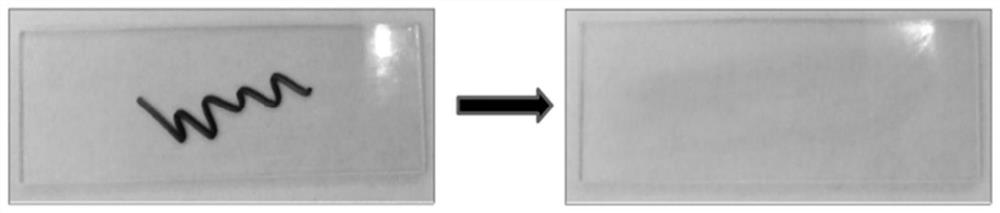

A kind of light curing anti-graffiti paint with self-healing function and its preparation method and application

A light-curing and anti-graffiti technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of no self-repair function, the decline of surface anti-graffiti performance, and the long-term service of the coating, so as to achieve less energy consumption, The function is not easy to lose, and the effect of high-quality weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

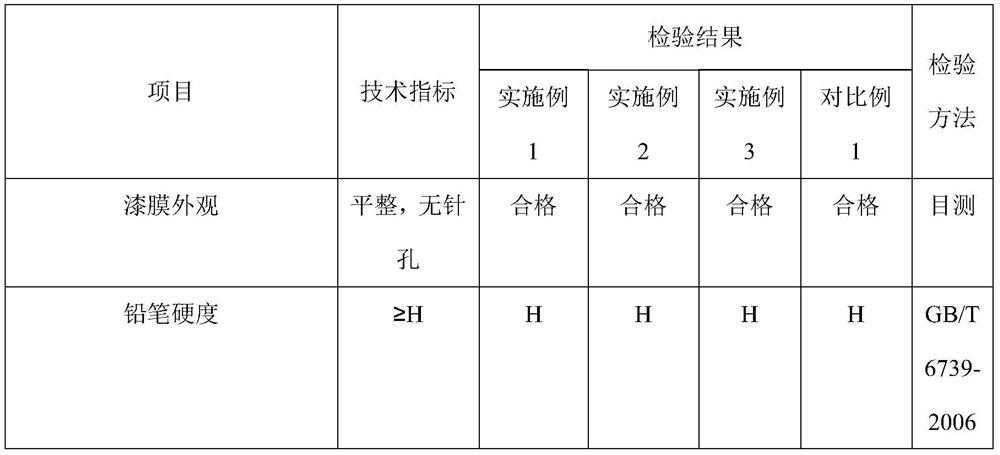

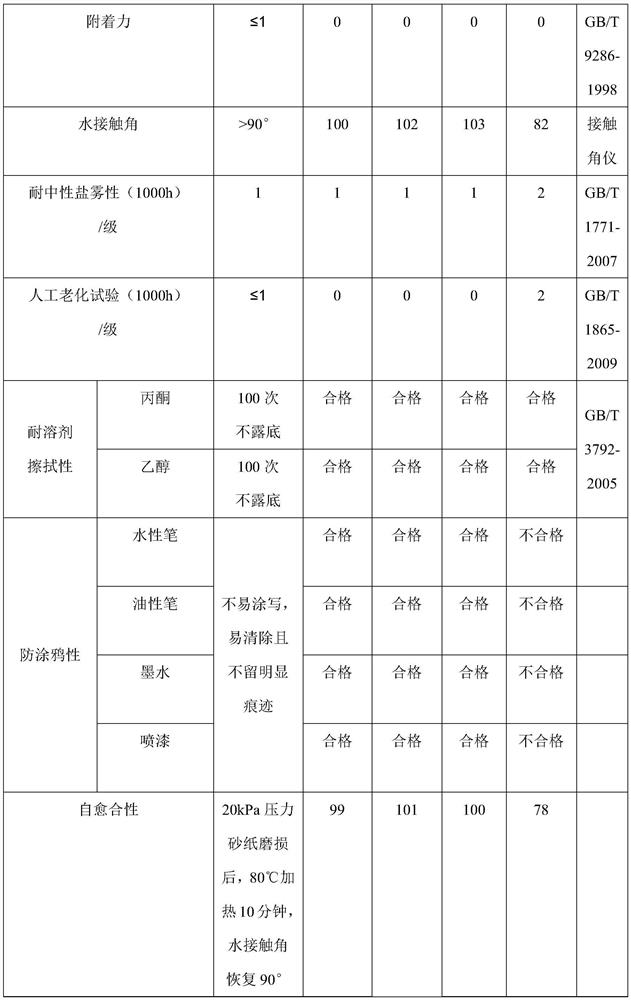

Examples

Embodiment 1

[0036](1) First add 100 mL of ethanol and 1.2 parts by mass of tridecafluorooctyltriethoxysilane (the mass volume ratio of fluorosilane to ethanol is 12 g / L) in a 250 mL beaker, and then add 9 parts by mass of titanium dioxide after stirring evenly Nanoparticles and 0.6 parts by mass of ammonia water (mass fraction 28%) were sonicated for 10 minutes, stirred and reacted at a temperature of 60° C. for 24 hours, washed and dried to obtain modified titanium dioxide nanoparticles.

[0037] (2) 4 parts by mass of isophorone diisocyanate, 7 parts by mass of polyethylene glycol (molecular weight: 400 g / mol) and 8 parts by mass of hydroxyl-terminated fluorine-containing silicone oil (molecular weight: 1000 g / mol) were dissolved in 10 parts by mass A uniform mixed solution was obtained in acetone, 0.2 parts by mass of dibutyltin dilaurate was added, and the reaction was stirred at 60 °C for 4 hours, then slowly cooled to 40 °C, and then 5 parts by mass of pentaerythritol triacrylate, 0....

Embodiment 2

[0040] (1) First add 130 mL of tetrahydrofuran and 1.5 parts by mass of heptadecafluorodecyltrimethoxysilane (the mass volume ratio of fluorosilane to tetrahydrofuran is 11.5 g / L) in a 250 mL beaker, and then add 8 parts by mass of two Silica nanoparticles and 1 mass part of ammonia water (mass fraction 28%) were sonicated for 10 min, stirred and reacted at a temperature of 65° C. for 24 h, washed and dried to obtain modified silica nanoparticles.

[0041] (2) 2 parts by mass of hexamethylene diisocyanate, 9 parts by mass of polycarbonate diol (molecular weight: 1000 g / mol) and 6 parts by mass of hydroxyl-terminated fluorosilicone oil (molecular weight: 2000 g / mol) were dissolved in 20 parts by mass of 0.2 parts by mass of pentamethyldiethylenetriamine was added into the tetrahydrofuran and 0.2 parts by mass of pentamethyldiethylenetriamine was added. After stirring and reacting at 60 ° C for 5 hours, the temperature was slowly lowered to 40 ° C. Then 4 parts by mass of dipenta...

Embodiment 3

[0044] (1) First add 120 mL of butyl acetate and 2 parts by mass of dodecafluoroheptylpropyl trimethoxysilane (the mass volume ratio of fluorosilane to butyl acetate is 16.7 g / L) in a 250 mL beaker, and after stirring evenly 10 parts by mass of zirconium dioxide nanoparticles and 1.5 parts by mass of ammonia water (28% by mass) were added, and after sonication for 15 minutes, the reaction was stirred at a temperature of 65° C. for 24 hours, washed and dried to obtain modified zirconium dioxide nanoparticles.

[0045] (2) 4.5 parts by mass of hexamethylene diisocyanate, 8 parts by mass of polypropylene glycol (molecular weight: 600 g / mol) and 9 parts by mass of hydroxyl-terminated fluorine-containing silicone oil (molecular weight: 1000 g / mol) were dissolved in 15 parts by mass of tetrahydrofuran A uniform mixed solution was obtained, 0.3 parts by mass of N,N'-lutidine was added, and after stirring and reacting at 60 °C for 4 hours, the temperature was slowly lowered to 40 °C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com