Degradable medical epidemic prevention packaging film and production process thereof

A production process and packaging film technology, applied in the field of medical anti-epidemic packaging film, can solve the problems of high production cost, mismatch between layers, incomplete degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

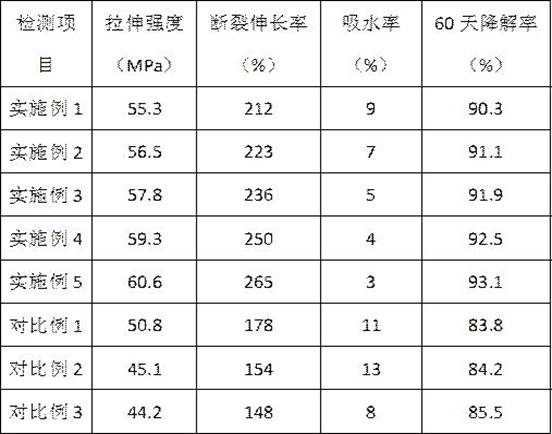

Examples

Embodiment 1

[0028] A kind of production technology of degradable medical anti-epidemic packaging film is characterized in that, comprises the steps:

[0029] Step S1, preparation of copolymer: allyl succinimidyl carbonate, GAMMA-butyrolactone-3-yl methacrylate, 5-vinylbicyclo[2.2.1]hept-2-ene, 2 -[3-(2H-Benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2-methacrylate and initiator are added to the high boiling point solvent, stirred at 70°C in an inert gas atmosphere After reacting for 3 hours, it was precipitated in water, and the precipitated polymer was washed 3 times with dichloromethane, and then dried to a constant weight in a vacuum oven at 85°C to obtain a copolymer;

[0030] Step S2, forming the primary product of the packaging film: mix the copolymer, epoxy vegetable oil, and hyperbranched starch prepared in step S1 evenly to obtain a mixed material, and then heat-melt the mixed material through a single-screw extrusion film blowing machine Extruded and blown into plastic film to obtain...

Embodiment 2

[0037] A kind of production technology of degradable medical anti-epidemic packaging film is characterized in that, comprises the steps:

[0038] Step S1, preparation of copolymer: allyl succinimidyl carbonate, GAMMA-butyrolactone-3-yl methacrylate, 5-vinylbicyclo[2.2.1]hept-2-ene, 2 -[3-(2H-Benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2-methacrylate and initiator are added to the high boiling point solvent, stirred at 73°C in an inert gas atmosphere After reacting for 3.5 hours, it was precipitated in water, and the precipitated polymer was washed 4 times with dichloromethane, and then dried in a vacuum oven at 87°C to constant weight to obtain a copolymer;

[0039] Step S2, forming the primary product of the packaging film: mix the copolymer, epoxy vegetable oil, and hyperbranched starch prepared in step S1 evenly to obtain a mixed material, and then heat-melt the mixed material through a single-screw extrusion film blowing machine Extruded and blown into plastic film to obtain...

Embodiment 3

[0045] A kind of production technology of degradable medical anti-epidemic packaging film is characterized in that, comprises the steps:

[0046] Step S1, preparation of copolymer: allyl succinimidyl carbonate, GAMMA-butyrolactone-3-yl methacrylate, 5-vinylbicyclo[2.2.1]hept-2-ene, 2 -[3-(2H-Benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2-methacrylate and initiator are added to the high boiling point solvent, stirred at 75°C in an inert gas atmosphere After reacting for 4 hours, it was precipitated in water, and the precipitated polymer was washed 6 times with dichloromethane, and then dried in a vacuum oven at 90°C to constant weight to obtain a copolymer;

[0047] Step S2, forming the primary product of the packaging film: mix the copolymer, epoxy vegetable oil, and hyperbranched starch prepared in step S1 evenly to obtain a mixed material, and then heat-melt the mixed material through a single-screw extrusion film blowing machine Extruded and blown into plastic film to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com