Corrosion-resistant thermal insulation ceramic material and preparation method thereof

A thermal insulation ceramic and corrosion-resistant technology, applied in the field of ceramic materials, can solve problems such as affecting ceramic production and inconvenient ceramic sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

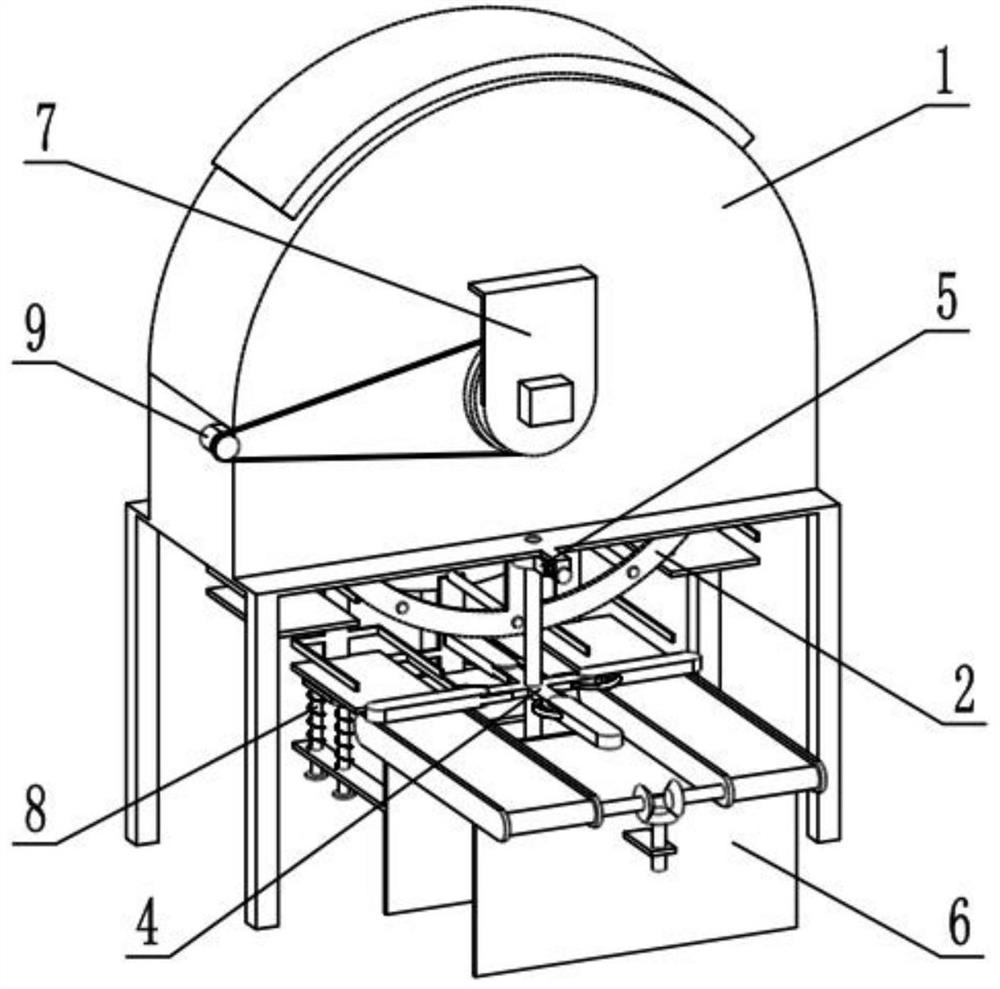

[0037] Such as Figure 1-13 Shown, a kind of corrosion-resistant thermal insulation ceramic material preparation method comprises the following steps:

[0038] Step 1, mix the raw materials evenly;

[0039] Step 2, heating and extruding the mixture obtained in Step 1 into a ceramic green body;

[0040] Step 3, sintering the ceramic green body, and naturally cooling to room temperature to obtain a corrosion-resistant and heat-preserving ceramic material;

[0041] The above-mentioned method for preparing a corrosion-resistant and heat-preserving ceramic material also involves a preparation device for a corrosion-resistant and heat-preserving ceramic material;

[0042] The preparation device for a corrosion-resistant and heat-preserving ceramic material includes a calcining box 1, a carrier frame 2, a transmission mechanism 3, a toggle mechanism 4, a control mechanism 5, a conveying mechanism 6, an air suction mechanism 7 and a motor 9. The bearing frame 2 is rotatably connect...

specific Embodiment approach 2

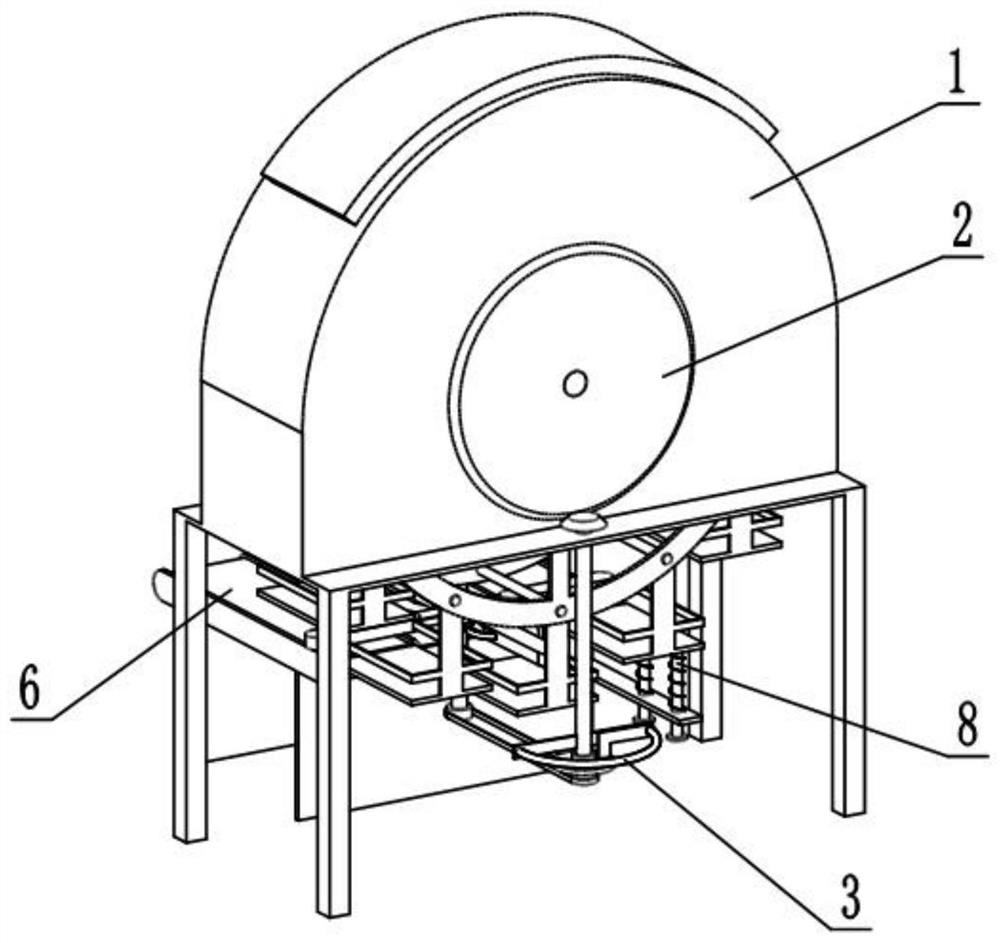

[0045] Such as Figure 1-13 As shown, the calcined box 1 includes a semicircle box 1-1, a leg frame 1-2 and a connecting plate 1-3, the inside of the semicircle box 1-1 is provided with a heating plate, and the semicircle box 1-1 The lower end of the semicircular box body 1-1 is hollowed out, the front and rear sides of the lower end of the semicircular box body 1-1 are fixedly connected with outriggers 1-2, and the middle part of the outriggers 1-2 on the front side is fixedly connected with a connecting plate 1-3, and the motor 9 It is fixedly connected to the semicircular box body 1-1.

[0046] The heating plate inside the semicircular box 1-1 is used to heat the inside of the semicircular box 1-1 to form the sintering of the ceramic green body.

specific Embodiment approach 3

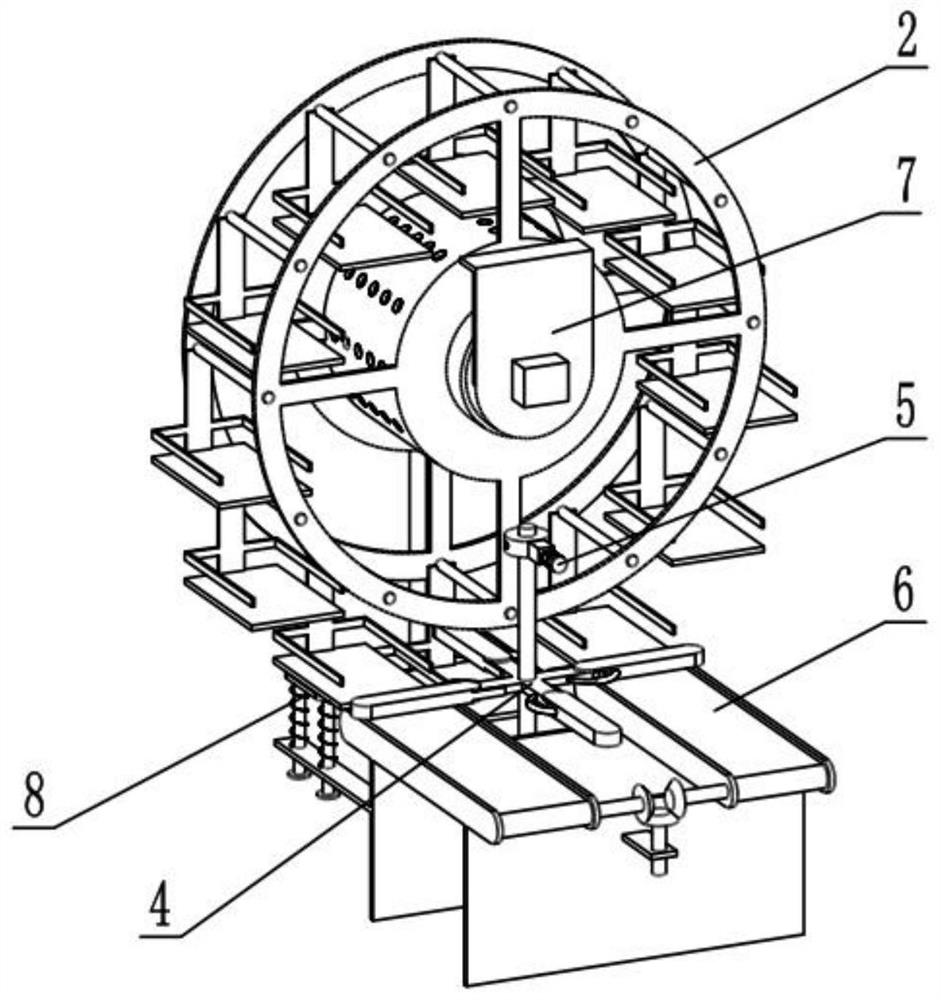

[0048] Such as Figure 1-13 As shown, the carrier frame 2 includes an outer connecting ring 2-1, a connecting shaft 2-2, a carrier frame 2-3, a limiting plate 2-4, a central tube 2-5, a rotating tube 2-6 and a transmission gear Ⅰ2-7, the central tube 2-5 is provided with a plurality of ventilation holes, the two ends of the central tube 2-5 are respectively fixedly connected with the rotating tube 2-6 and the transmission gear Ⅰ2-7, and the outer end of the central tube 2-5 is fixed Two outer connecting rings 2-1 are connected, and a plurality of connecting shafts 2-2 are evenly and fixedly connected in the circumferential direction between the two outer connecting rings 2-1, and a bearing frame 2 is connected to the plurality of connecting shafts 2-2 in rotation -3, the lower ends of the plurality of bearing frames 2-3 are provided with counterweights, and the plurality of bearing frames 2-3 are provided with limiting plates 2-4, and the central tube 2-5 is located in the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com