Geshi metal glaze with copper red metal texture and processing technology thereof

A technology of metal texture and processing technology, applied in the field of Grignard metallic glaze, can solve the problems of restricting the wide application of glaze, discounting and monotony of decorative embellishment effect of products, and achieve increased added value and market competitiveness, excellent decorative embellishment effect, The effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

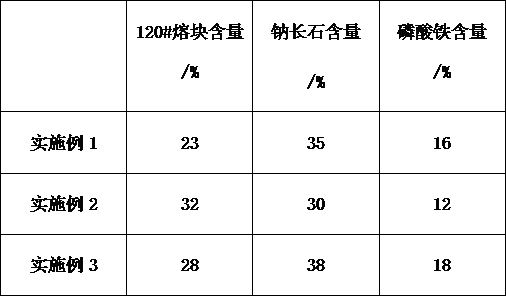

[0027] A Grignard metallic glaze with a copper-red metallic texture, the formula includes: ultra-white washing mud, lithified silicon powder, 120# frit, albite, iron phosphate, zinc oxide, color developer and cerium oxide, each group The mass percentages of the points are: 6% ultra-white washing mud, 3% lithified silicon powder, 23% 120# frit, 35% albite, 16% iron phosphate, 2% oxidized Zinc, 6% developer and 9% cerium oxide.

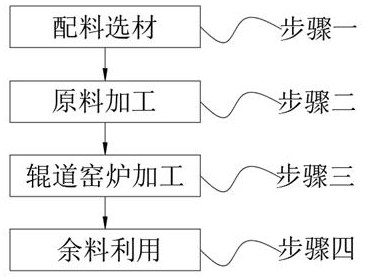

[0028] A processing technique for Grignard metallic glaze with a copper-red metallic texture, comprising the following steps: Step 1, ingredient selection; Step 2, raw material processing; Step 3, roller kiln processing; Step 4, surplus material utilization;

[0029] Wherein in the above-mentioned step one, the mass percent composition by each component is respectively: 6% ultra-white washing mud, 3% lithified silicon micropowder, 23% 120# frit, 35% albite, 16 % ferric phosphate, 2% zinc oxide, 6% developer and 9% cerium oxide are selected, and weighed...

Embodiment 2

[0040] A Grignard metallic glaze with a copper-red metallic texture, the formula includes: ultra-white washing mud, lithified silicon powder, 120# frit, albite, iron phosphate, zinc oxide, color developer and cerium oxide, each group The mass percentages of the points are: 6% ultra-white washing mud, 3% lithified silicon powder, 32% 120# frit, 30% albite, 12% iron phosphate, 2% oxidized Zinc, 6% developer and 9% cerium oxide.

[0041] A processing technique for Grignard metallic glaze with a copper-red metallic texture, comprising the following steps: Step 1, ingredient selection; Step 2, raw material processing; Step 3, roller kiln processing; Step 4, surplus material utilization;

[0042] Wherein in the above-mentioned step 1, the mass percent composition by each component is respectively: 6% ultra-white washing mud, 3% lithified silicon micropowder, 32% 120# frit, 30% albite, 12 % ferric phosphate, 2% zinc oxide, 6% developer and 9% cerium oxide are selected, and weighed a...

Embodiment 3

[0053] A Grignard metallic glaze with a copper-red metallic texture, the formula includes: ultra-white washing mud, lithified silicon powder, 120# frit, albite, iron phosphate, zinc oxide, color developer and cerium oxide, each group The mass percentages of the points are: 6% ultra-white washing mud, 3% lithified silicon powder, 28% 120# frit, 38% albite, 18% iron phosphate, 2% oxidized Zinc, 6% developer and 9% cerium oxide.

[0054] A processing technique for Grignard metallic glaze with a copper-red metallic texture, comprising the following steps: Step 1, ingredient selection; Step 2, raw material processing; Step 3, roller kiln processing; Step 4, surplus material utilization;

[0055] Wherein in the above-mentioned step 1, the mass percent composition by each component is respectively: 6% ultra-white washing mud, 3% lithified silicon micropowder, 28% 120# frit, 38% albite, 18% % ferric phosphate, 2% zinc oxide, 6% developer and 9% cerium oxide are selected, and weighed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com