Fluorine-containing industrial wastewater treatment system and treatment method thereof

A technology for industrial wastewater and treatment systems, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large amount of sludge generation, high moisture content, high treatment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

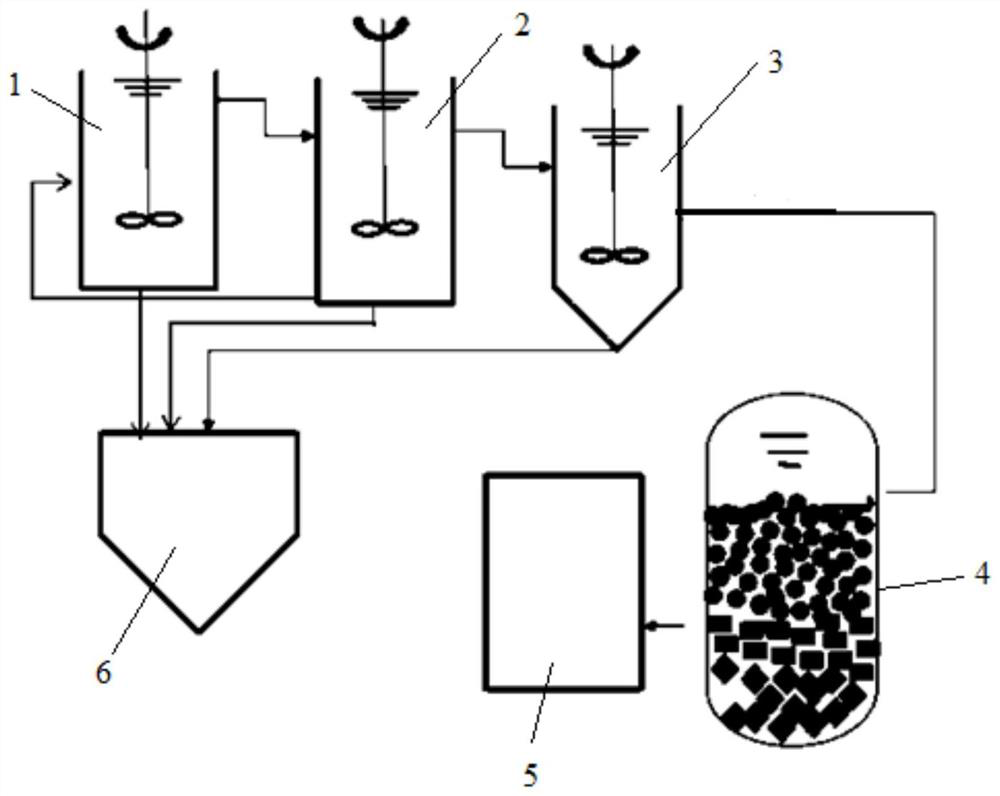

[0047] Such as figure 1 As shown, a fluorine-containing industrial wastewater treatment system includes a first-stage coagulation-sedimentation reaction tank 1, a second-order coagulation-sedimentation reaction tank 2, a mechanical stirring clarifier 3, a fluorine-removing resin tank 4 and a clear water tank 5 connected in sequence; And the first-level coagulation-sedimentation reaction tank 1, the second-level coagulation-sedimentation reaction tank 2, and the mechanical agitation clarification tank 3 adopt sequential drop settings, so that the waste water is automatically sequenced in the first-level coagulation-sedimentation reaction tank 1 and the second-level coagulation-sedimentation reaction tank Pond 2, mechanical agitation clarifier 3 continuous processing; The first-stage coagulation-sedimentation reaction tank 1, the second-stage coagulation-settling reaction tank 2 and mechanical agitation clarification tank 3 are also connected to the sludge sedimentation tank 6 by...

Embodiment 2

[0054] A method for treating fluorine-containing industrial wastewater, the method comprising the steps of:

[0055] (1) pH adjustment: Pour 5L of industrial wastewater with a fluorine concentration of 150ppm into the primary coagulation sedimentation reaction tank 1, and add calcium chloride to adjust the pH of the industrial wastewater to 11.5;

[0056] (2) One-time defluorination: according to Ca 2+ :F - =5:1 (molar ratio) add calcium chloride, stir for 30 minutes, then add calcium phosphate, and ensure that the added calcium ions and the fluoride ions in the initial solution are in accordance with the Ca 2+ : calcium phosphate: F - =5:3:1 Dosing of medicaments, stirring for 30min, and finally, separating the sedimentation and supernatant of the treated wastewater; in addition, during a defluorination period, the sedimentation is discharged into the sludge sedimentation tank 6 every 30min, every Second row 3min;

[0057] (3) Secondary defluorination: import the waste wa...

Embodiment 3

[0063] For the hydrofluoric acid soaking liquid wastewater in the photovoltaic semiconductor industry, the concentration of fluoride ions contained in the wastewater is 5g / L.

[0064] A method for treating fluorine-containing industrial wastewater, the method comprising the steps of:

[0065] (1) Evaporation: After putting 1L of high fluorine-containing wastewater into the PE raw water bucket, add 13g of sulfuric acid with a content of 98% to increase the concentration of hydrofluoric acid in the wastewater, and then transport it to the evaporation tower through a rubber-lined PTFE pipeline. Hydrofluoric acid is concentrated and purified, and hydrofluoric acid wastewater is converted into hydrofluoric acid raw material, and the generated hydrofluoric acid can be reused in industry, such as etching glass, or removing oxides in the semiconductor industry, so as to realize the recycling of wastewater; finally , Collect about 400-600ml of high-concentration hydrofluoric acid for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com