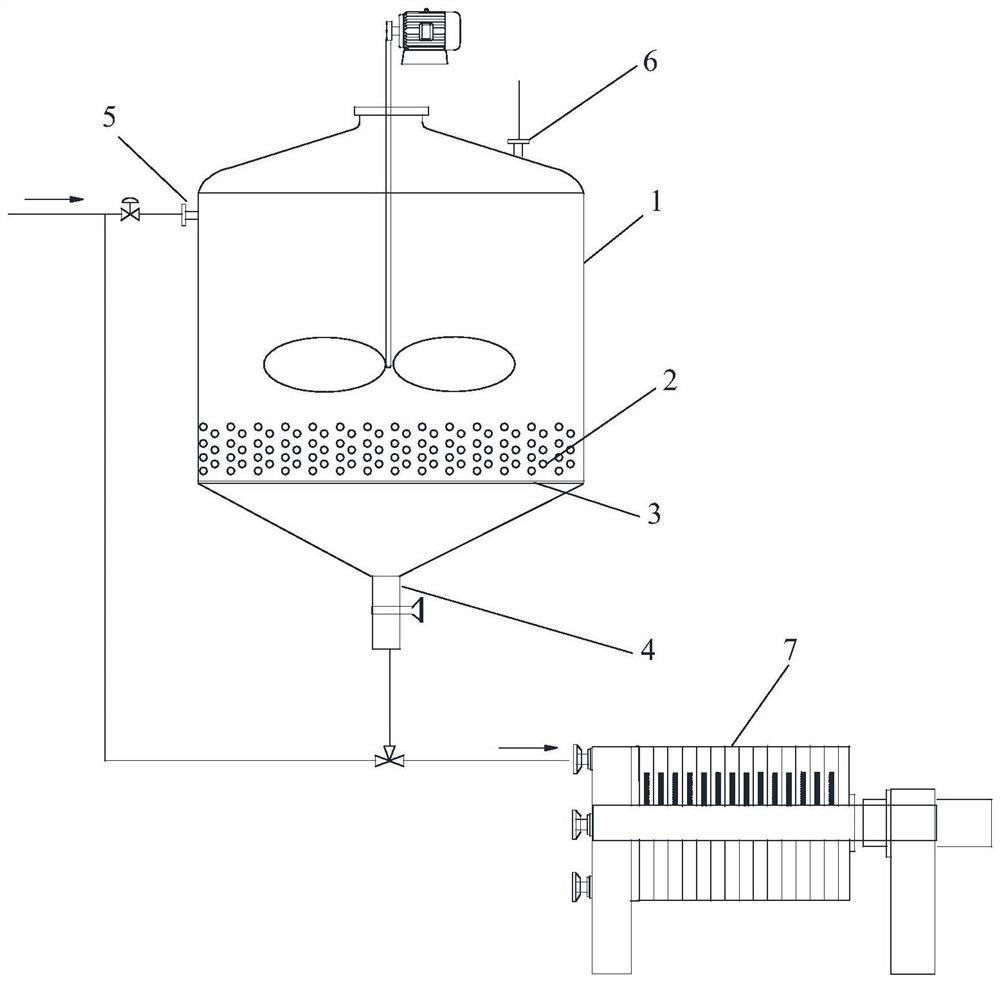

Method and equipment for treating pollutants in water by using aluminum alloy particles

A technology for aluminum alloys and pollutants, applied in water/sewage treatment, chemical instruments and methods, reduced water/sewage treatment, etc., can solve problems such as the existence of surface oxide layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Melting the aluminum ingot and adding a catalyst, the catalyst is an indium-bismuth alloy (the mass ratio of indium and bismuth is 2:1), and the mass of the catalyst accounts for 0.1% of the total mass of the raw material; after all the metals are melted into molten alloy liquid , using a vacuum metal granulator to cast the molten alloy liquid into aluminum alloy particles with a particle size of 2-5mm;

[0042] 2) adding the aluminum alloy particles to the sewage processor, adding sewage with a neutral pH value (pH7) for reaction, sampling and monitoring changes in pollutant concentration during the reaction until all pollutants are removed;

[0043] 3) After the reaction is complete, the reaction mixture is removed from the processor and filtered to obtain clear water.

[0044] In this embodiment, methyl orange is used to prepare simulated sewage, and a water treatment test is carried out to obtain suitable water treatment conditions.

[0045] Weigh 0.5g of alumin...

Embodiment 2

[0047] The aluminum alloy particles with a particle size of 2-5mm are prepared in the same way as in Example 1.

[0048] Weigh 0.5g of aluminum alloy particles with a particle size of 2mm, put them into 100mL of water with a methyl orange concentration of 10mg / L, the water temperature is 25°C, and the stirring speed is 50r / min. The concentration of pollutants is detected by colorimetry, and the methyl orange is recorded. Fade time, the time for complete fading is 20min.

[0049] The use of aluminum alloy particles with small particle size and large specific surface area can significantly improve the efficiency of water treatment.

Embodiment 3

[0051] The aluminum alloy particles with a particle size of 2-5mm are prepared in the same way as in Example 1.

[0052]Put 10g of aluminum alloy particles with a particle size of 2mm into 500ml of wastewater prepared with copper sulfate with a copper ion content of 100mg / L. The water temperature is 25°C and the stirring speed is 50r / min. After 30min, the copper ion content reaches undetectable , to achieve the effective removal of copper ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com