Artwork manufacturing method adopting 3D-printed sand mold

A technology of 3D printing and production method, applied in the field of 3D printing, can solve the problems of printing surface roughness, uneven printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

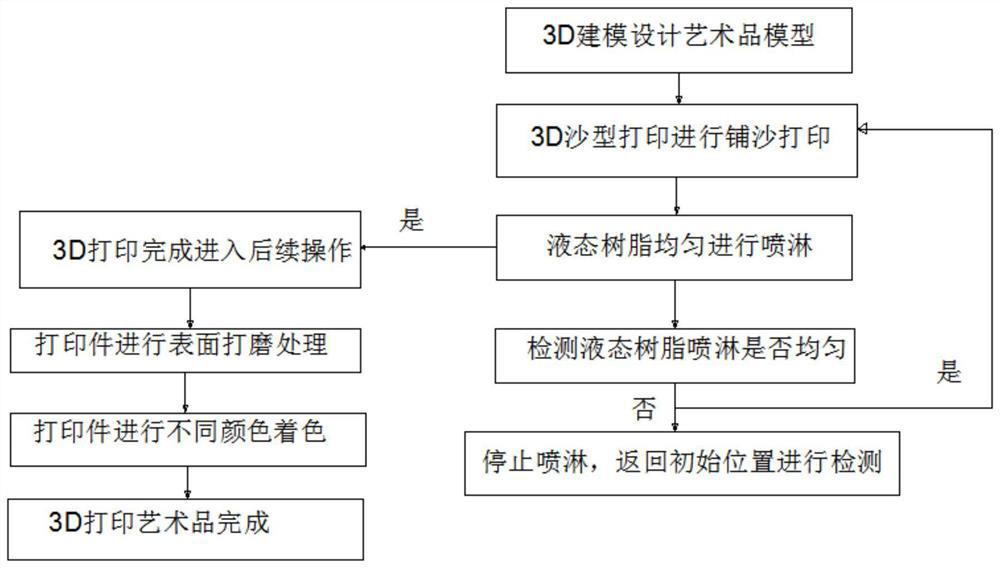

[0033] A kind of 3D printing sand mold artwork production method, comprises the following steps:

[0034] S1: Complete the initial modeling of artworks through 3D modeling, and print the modeling drawings through 3D printing equipment;

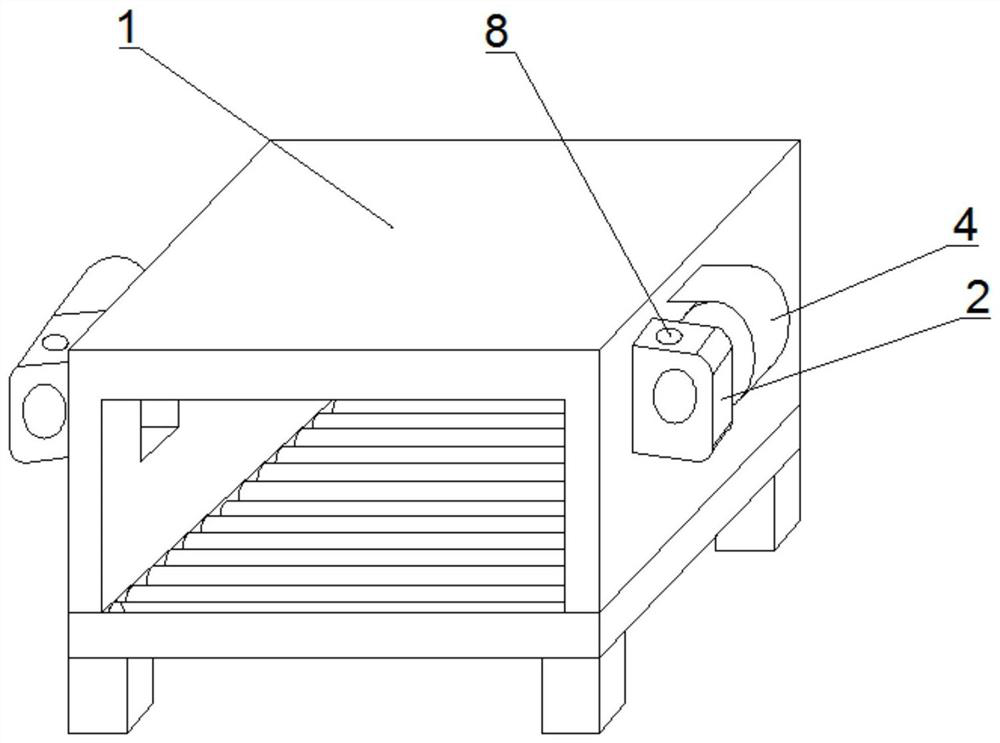

[0035] S2: Perform multi-layer sand topping operation according to the sand topping device of the 3D printing equipment, and the thickness of each layer of sand topping is controlled at 0.1-0.35mm;

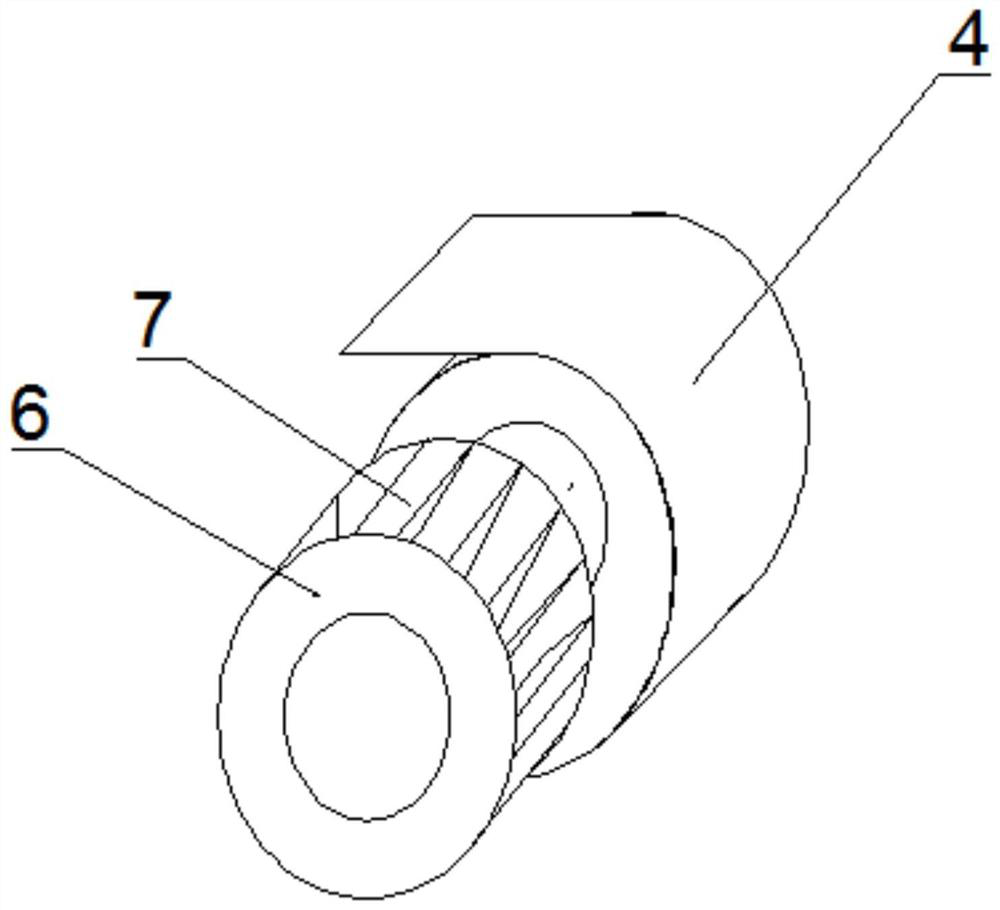

[0036] S3: After the sand topping is completed, the liquid resin is evenly sprayed through the spray micropores of the spray device;

[0037] S4: After step S3 is completed, scan and detect the spraying position through the detection device, and compare the cross-section of the three-dimensional modeling figure with the spraying figure of the spraying device through the scanning test to check whether the spraying position and spraying are uniform, if Spray evenly and continue to step S2;

[0038] S5: When the spraying is uneven, the spraying mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com