Heat dissipation device for electric power engineering equipment

A technology for heat dissipation of equipment and power engineering, applied in the direction of cooling/ventilation of substations/switchgears, etc., can solve problems such as unfavorable saving of water resources, inability to reduce the temperature of power equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

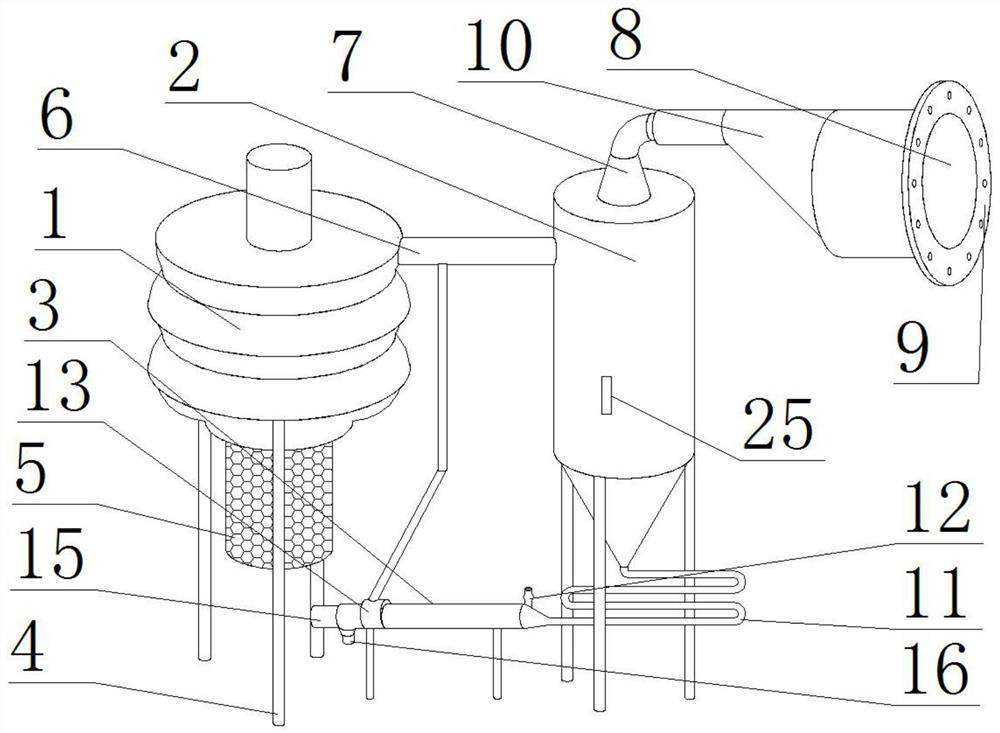

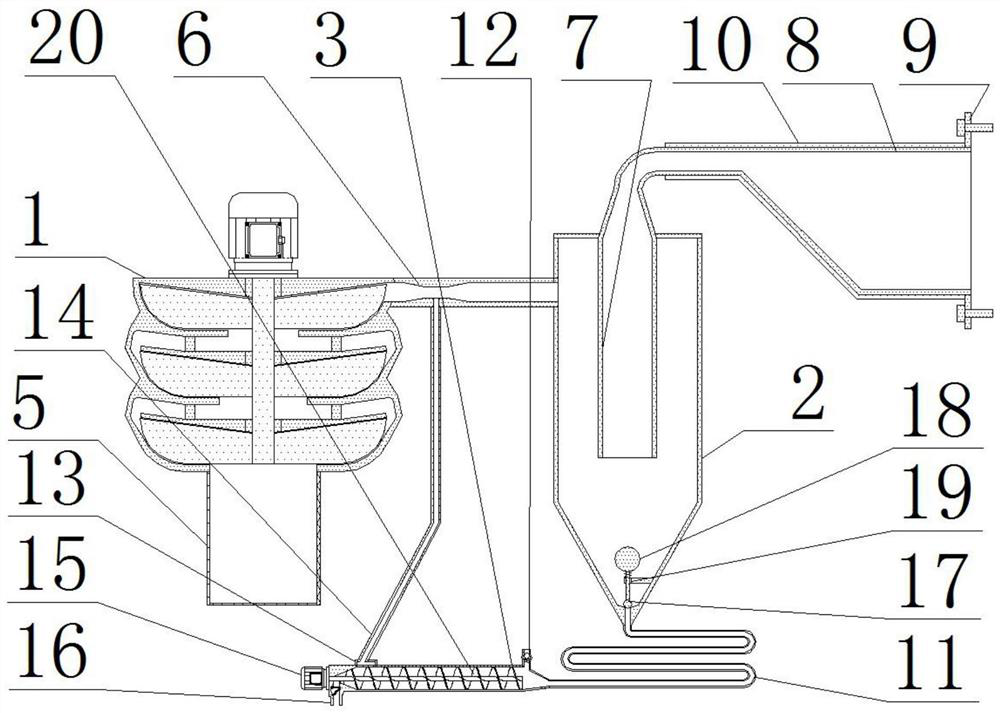

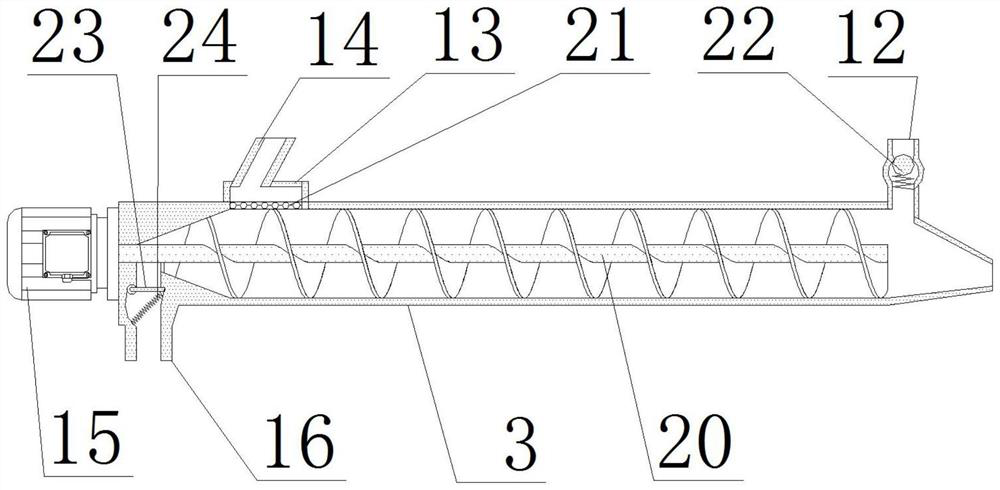

[0025]As a preferred embodiment of the present invention, the high-pressure fan 1 communicates with one side of the cyclone 2 through the Venturi tube 6, and the bottom end of the outlet pipe 7 passes through the cyclone 2 and extends to the bottom of the cyclone 2. In the middle part, the high-pressure air forms a high-speed airflow in the middle of the Venturi tube 6. At this time, the water is dispersed and atomized by the high-speed airflow in the Venturi tube 6, and after fully contacting with the high-temperature air, the water mist can absorb the heat in the high-temperature air , to cool down the high temperature gas.

[0026] As a preferred embodiment of the present invention, the bottom of the cyclone 2 is provided with a through hole, the cyclone 2 communicates with the heat dissipation pipe 11 through the through hole, and the bottom end of the plug 17 is stuck in the through hole. top.

[0027] As a preferred embodiment of the present invention, one side of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com