Method for increasing zinc doping concentration in indium phosphide

A technology of doping concentration and indium phosphide, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that it is difficult to obtain P-type InP, etc., and achieve the goal of improving internal quantum efficiency, reducing thickness and manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

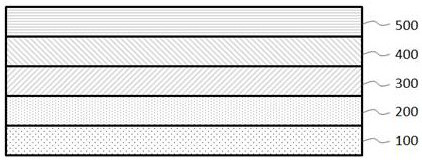

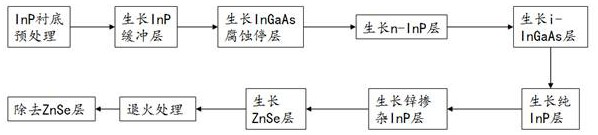

[0086] In this embodiment, a semi-finished infrared epitaxial wafer is prepared, and the specific process is as follows:

[0087] S1. Using Veeco K475 MOCVD, under the pressure of 39torr and temperature of 620℃, the surface pretreatment of InP substrate was carried out for 6min;

[0088]S2. Using the above-mentioned MOCVD instrument, grow a 0.5um thick InP buffer layer on the surface of the InP substrate at a temperature of 580°C, with a growth rate of 0.5um / h;

[0089] S3. Using the above-mentioned MOCVD instrument, grow a 0.2um thick InGaAs corrosion stop layer on the surface of the InP buffer layer at a temperature of 630°C, with a growth rate of 2.6um / h;

[0090] S4. Using the above-mentioned MOCVD instrument, grow a 0.1um thick n-InP layer on the surface of the InGaAs etching stop layer at a temperature of 580°C, with an n-type doping concentration of 4×10 18 cm -3 , the growth rate is 0.5um / h;

[0091] S5. Using the above-mentioned MOCVD instrument, grow a 2.5um thick...

Embodiment 2

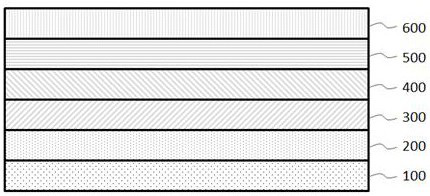

[0093] In this embodiment, an infrared epitaxial wafer comprising indium phosphide material with a high zinc doping concentration is prepared, and the specific process is as follows:

[0094] S1. Using the same MOCVD instrument as in Example 1, at a temperature of 580° C., on the surface of the i-InGaAs layer of the semi-finished infrared epitaxial wafer obtained in Example 1, grow a 0.2um thick p-InP layer. The average zinc (p type) with a doping concentration of 10 19 cm -3 , the growth rate is 0.5um / h; where the p-InP layer includes a 0.14um thick pure InP layer grown sequentially on the surface of the i-InGaAs layer, and a 0.06um thick zinc-doped InP layer; when growing a zinc-doped InP layer, The zinc source is dimethyl zinc, the zinc source feed time is 140s, and the feed rate is 30 sccm;

[0095] Using the above-mentioned MOCVD instrument, grow a 0.05um thick ZnSe layer on the surface of the p-InP layer at a temperature of 500°C, with a growth rate of 5um / h;

[0096]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com