Pluggable rapid installation high-voltage bushing

A high-voltage bushing, plug-in technology, applied in the direction of transformer/inductor coil/winding/connection, insulator, etc., can solve the problem of incorrect position, oil pressure buffer between transformer bushing and base, bushing current-carrying rod and base The connecting rod is not concentric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

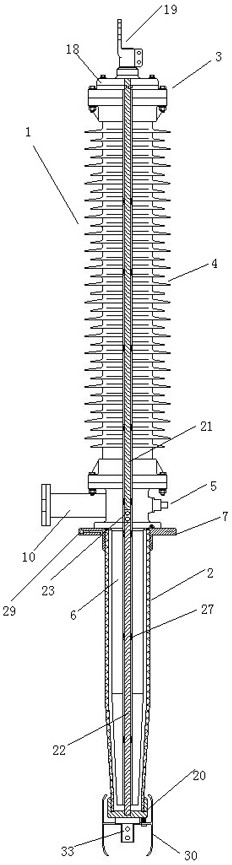

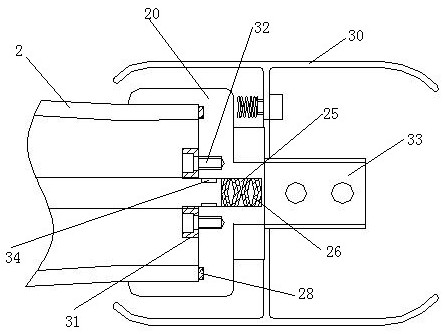

[0028] Such as Figure 1-4 Shown: This embodiment is a pluggable quick-installation high-voltage bushing, including a high-voltage bushing 1 and a base glass fiber reinforced plastic cylinder 2, and the high-voltage bushing 1 includes an upper head 3, a hollow composite sleeve 4, and a bushing flange 5 and the capacitor core 6, the upper head 3 is set on the top of the capacitor core 6, the sleeve flange 5 is set in the middle section of the core body of the capacitor core 6, and the hollow composite sleeve 4 is set on the upper cover 3 and the sleeve Outside the capacitor core 6 between the pipe flanges 5, the two ends of the hollow composite sleeve 4 are respectively flange-connected with the upper head 3 and the sleeve flange 5, and the capacitor core 6 located below the sleeve flange 5 is arranged on The interior of the base glass fiber reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com