Wet cooling unit cold end performance monitoring and intelligent diagnosis system for

An intelligent diagnosis and unit technology, applied in the direction of machine/structural component testing, water testing, measuring devices, etc., to achieve the effect of ensuring safe and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

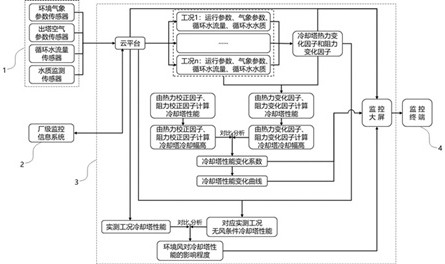

[0037] Such as figure 1As shown, a cold-end performance monitoring and intelligent diagnosis system of a wet-cooling unit in the present invention is mainly composed of a data acquisition system 1, a plant-level monitoring information system 2, an Internet of Things cloud platform 3, and a monitoring terminal 4. The data acquisition system 1 is equipped with an environmental meteorological Parameter sensor, tower air parameter sensor, circulating water flow sensor and water quality monitoring sensor, the monitoring data of each sensor can be sent to the Internet of Things cloud platform 3 by wireless transmission through the intelligent gateway; the factory-level monitoring information system 2 and the Internet of Things cloud platform 3 Data can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com