Double-effect air purification and sterilization equipment

A technology of air purification and equipment, which is applied in the field of double-effect air purification and sterilization equipment, can solve the problems of increasing quantity, slowing down of exhaust gas purification and sterilization, and slowing down of passing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

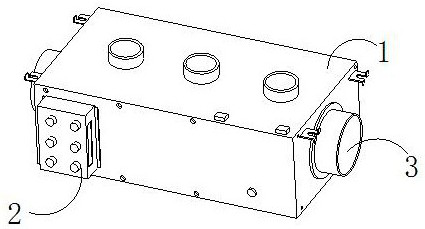

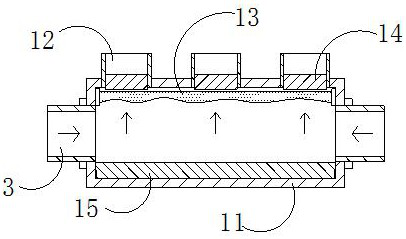

[0029]Appendfigure 1 AdherentFigure 6 Down:

[0030]The present invention provides a two-efficiency air purification and sterilization device comprising a body 1, a control case 2, a intake pipe 3, the receiving of the control box 2 on the back surface of the body 1 on the left end, and the air tube 3 is fixed in the body The middle of the two ends.

[0031]The body 1 includes a housing 11, an exhaust pipe 12, an absorbing web 13, a push mechanism 14, a collection mechanism 15, and the bottom end of the exhaust pipe 12 is fixed vertically at the top of the housing 11, and the absorbing network 13 and The housing 11 is coupled to the inner wall of the top end, and the push mechanism 14 is nested in the inner wall of the exhaust pipe 12, and the collecting mechanism 15 is attached to the bottom of the housing 11.

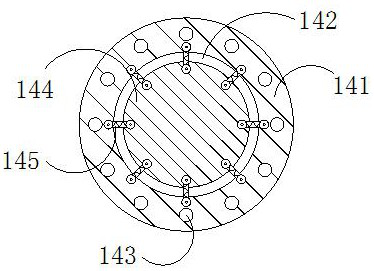

[0032]Wherein, the push mechanism 14 includes a support ring 141, a card slot 142, an exhaust hole 143, a sliding block 144, a reset strip 145, and the card slot 142 through the upp...

Embodiment 2

[0039]AppendFigure 7 AdherentFigure 9Down:

[0040]Wherein, the collecting mechanism 15 includes a support plate 15a, a collecting chamber 15b, a drainage groove 15c, a mating rod, a bounce 15e, and the collecting chamber 15b, the collecting chamber 15b is opened in the support plate 15a, and the introduction groove 15c penetrates the support plate 15a The upper surface and the interior, and in communication with the collecting chamber 15b, the bottom of the mating rod 15d is attached to the upper surface of the support plate 15a, and is located on the right side of the drainage groove 15c, the top of the bomb bar 15D and the middle bottom surface of the mating rod 15d Connection, the mating rod 15d is fitted with two identical rebound strips, respectively, can increase the driving force of the bounce 15e to the mating rod 15d, speed up the reset speed of the mating rod 15d, facilitating the top end of the drainage groove 15c is unblocked The shape such that the tar molecule flows alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com