Sewage treatment device with multi-mode operation

A sewage treatment device, multi-mode operation technology, applied in multi-stage water treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. And/or total phosphorus treatment to meet the standard and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

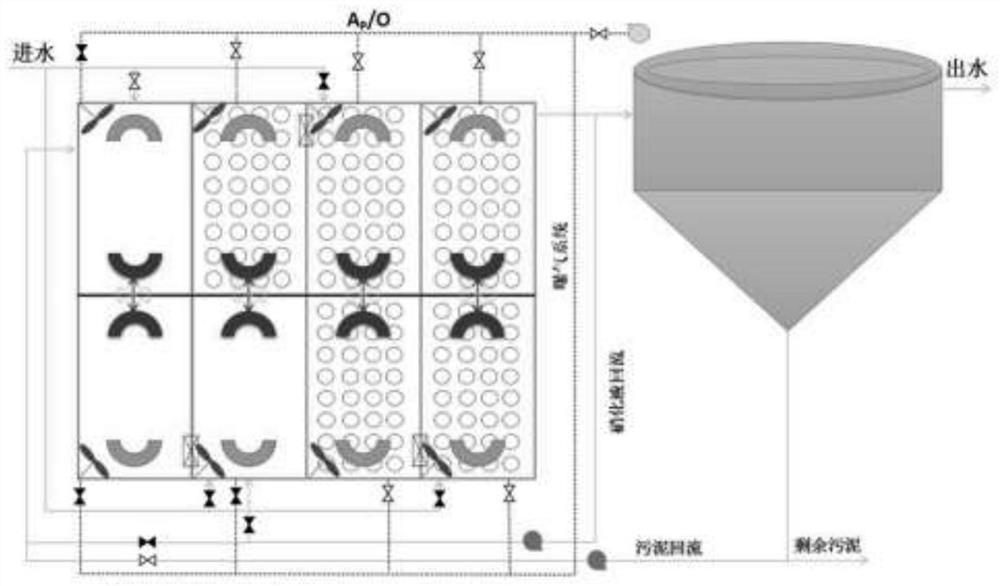

[0027] Operation mode one: anaerobic-aerobic (A P / O). Such as figure 2 As shown, open the water inlet valve V1, so that the sewage after the primary treatment of the sewage plant enters the anaerobic state (by closing the aeration valve AV1 corresponding to this small reverse tank, the anaerobic state is achieved, the same below) small reaction tank T1, in Under the impetus of the submersible flowmaker (M)) in the small reaction tank, the anaerobic (by closing the aeration valve AV2 corresponding to the small reaction tank to reach the anaerobic state, the same below) the small reaction tank T2, the anaerobic ( By closing the aeration valve AV3 corresponding to this small reaction tank, the anaerobic state is achieved, the same below) small reaction tank T3. The small reaction pools T1, T2, and T3 are connected through water holes at the bottom. At the same time, turn on the sludge return pump (P2) and return valve (RV3) of the system to return a certain amount of activat...

Embodiment 2

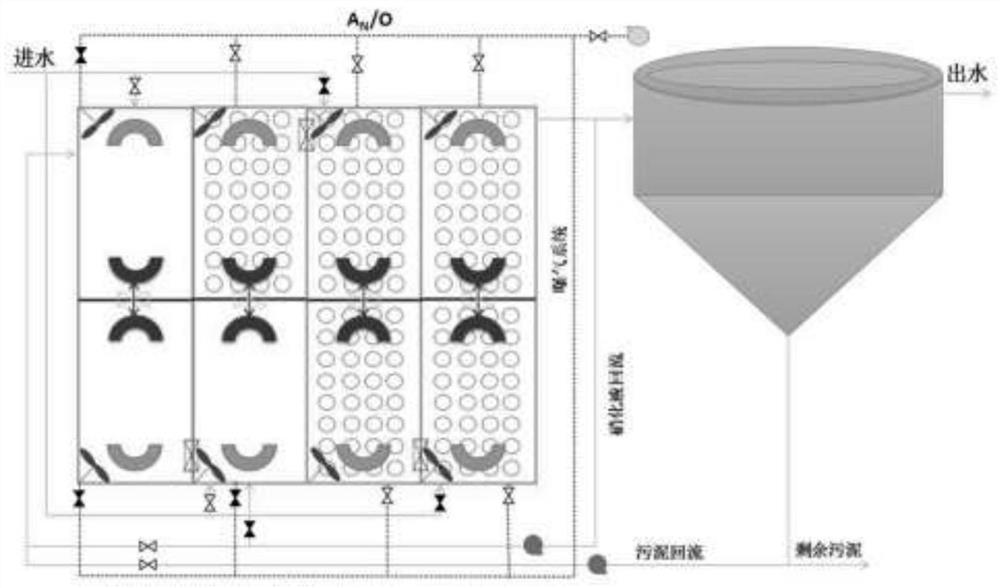

[0030]Operation mode two: anoxic-aerobic (A N / O). Such as image 3 As shown, open the water inlet valve V1, so that the sewage after the primary treatment of the sewage plant enters the anoxic state (by closing the aeration valve AV1 corresponding to this small reverse tank, the anoxic state is reached, the same below) small reaction tank T1, in Under the impetus of the submersible flowmaker (M) in the small reaction tank, the small reaction tank T2, the hypoxia (through Close the aeration valve AV3 corresponding to this small reaction tank to reach anoxic state, the same below) small reaction tank T3. The small reaction pools T1, T2, and T3 are connected through water holes at the bottom. At the same time, turn on the nitrification liquid return pump (P1), sludge return pump (P2) and return valve (RV2, RV3) of the system to transfer a certain amount of NO 3 -N and NO 2 -N aerobic tank mixed liquid is returned to the anoxic small reaction tank T1 to prepare for the denit...

Embodiment 3

[0033] Operation mode three: anaerobic-anoxic-aerobic (A / A / O). Such as Figure 4 As shown, open the water inlet valve V1, so that the sewage after the primary treatment of the sewage plant enters the anaerobic state (by closing the aeration valve AV1 corresponding to this small reverse tank, the anaerobic state is achieved, the same below) small reaction tank T1, in Under the impetus of the submersible flowmaker (M) in the small reaction tank, it enters the anaerobic (by closing the aeration valve AV2 corresponding to the small reaction tank, the anaerobic state is reached, the same below) small reaction tank T2. Afterwards, the sewage enters the anoxic (by closing the aeration valve AV3 corresponding to this small reverse tank, to reach the anoxic state, the same below) the small reaction tank T3, and under the impetus of the submersible flowmaker (M) in the small reaction tank, enters Hypoxia (by closing the aeration valve AV4 corresponding to this small reaction tank, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com