Preparation process for oil cooler pipe externally provided with reinforcing pieces

A preparation process and reinforcement sheet technology are applied in the field of preparation process of oil cooler tubes with outer reinforcement sheets, which can solve the problems of slow production, manual production, low work efficiency, etc., and achieve low production efficiency, slow operation speed, and heat exchange. effect reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

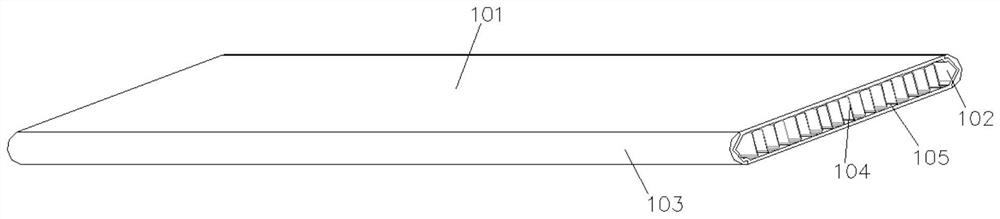

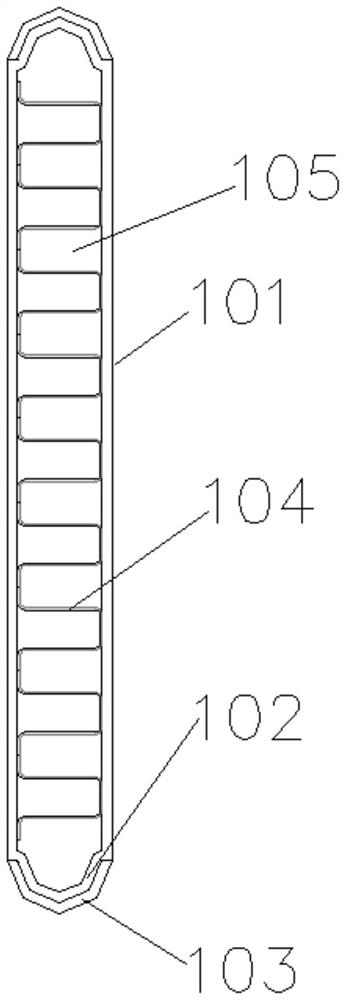

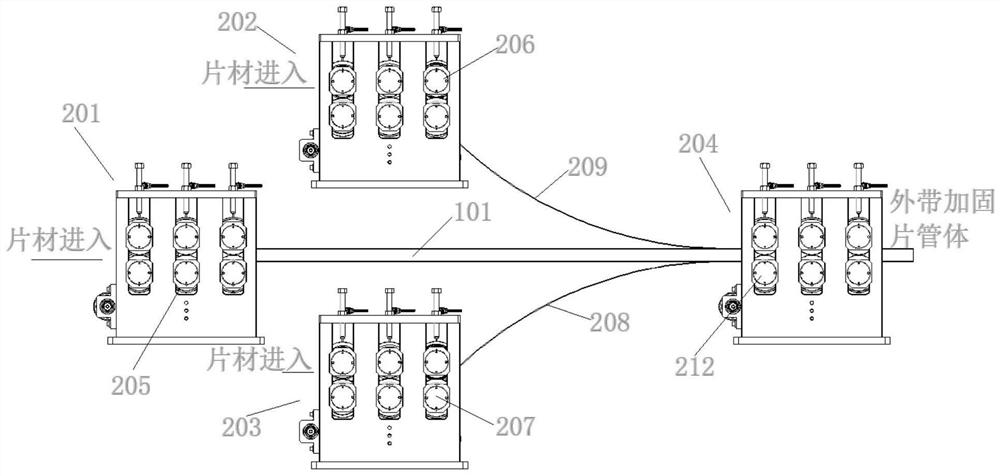

[0035] like figure 1 As shown in the figure, an oil cooler tube with outer reinforcement sheet includes a tube body 101, the tube body 101 is a flat tube body, and both sides of the tube body 101 are provided with arc-shaped convex strips 102. The outer side of the convex strip 102 is closely covered with an arc-shaped reinforcing piece 103, and the outer surface of the reinforcing piece 103 is smoothly connected with the upper and lower sides of the tube body 101. The tube body 101 is provided with fins 104, and the fins 104 The spoiler grooves 105 are arranged in a broken line to form a plurality of staggered notches, and the bearing capacity of the pipe body 101 can be increased by adding the reinforcement sheet 103. The reinforcement sheet 103 is arranged on the outside of the pipe body 101 to facilitate the use of mechanical equipment for automatic processing and assembly, speeding up production efficiency, and the prepared oil cooler tube is integrally bent from a sheet ...

Embodiment 2

[0053] In this embodiment, the material thickness of the reinforcing sheet is 0.5mm, the width of the bottom of the spoiler groove is 2.0mm, the angle between the two side walls of the spoiler groove is 4°, the cross-section of the pipe body is 30mm long, and the width is 4mm; other implementations are consistent with embodiment 1.

Embodiment 3

[0055] In this embodiment, the material thickness of the reinforcing sheet is 0.5 mm, the width of the bottom of the spoiler groove is 3.5 mm, the angle between the two side walls of the spoiler groove is 8°, the cross-section of the pipe body is 300 mm long, and the width is 20mm; other implementations are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com