Method of forming a perovskite film for an optoelectronic device

A technology for optoelectronic devices and perovskites, which is applied in the fields of electric solid devices, capacitors, photovoltaic power generation, etc., can solve the problem of not developing high-quality 2D perovskite film scalable technology, organic cations prone to hydrolysis reactions, affecting the device. performance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

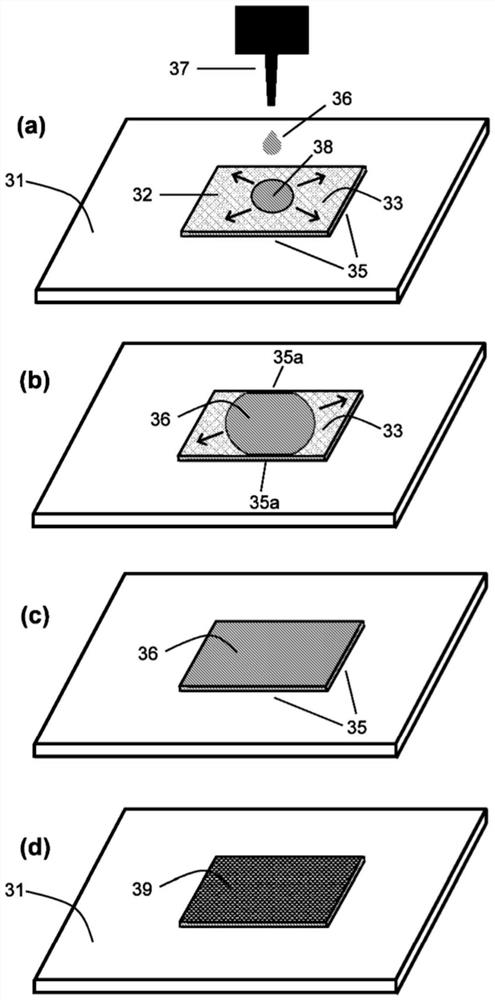

[0122] will now refer to figure 2 Embodiments of the present invention are described. As described herein, a hydrophilic layer 32 (eg, a printed PEDOT:PSS coating of about 30 nm thickness) is selectively positioned on a hydrophobic substrate 31 (eg, a PET film). Thus, the surface of the hydrophilic layer 32 presents a rectangular hydrophilic region 33 delimited by hydrophobic boundaries 35 formed by adjacent regions of the substrate 31 .

[0123] Substrate 31 is heated to a temperature of about 60°C to 70°C, for example by a heated backing plate (not shown). Such as figure 2 As shown in (a), the perovskite precursor solution 36 is then drop-coated from an applicator 37 (such as a needle) onto the central portion 38 of the hydrophilic region 33 . The perovskite precursor solution 36 may be a 2D perovskite precursor solution, for example, PbI in a molar ratio of 4:3:2 in DMF 2 , MAI and BAI solutions with a Pb concentration of about 0.3 mol / liter. Due to the hydrophilicit...

Embodiment 1

[0149] Embodiment 1. Preparation of perovskite precursor solution

[0150] 2D perovskite (BA) was prepared by 2 (MA) 3 Pb 4 I 13 Precursor solution: PbI with a molar ratio of 4:3:2 in dimethylformamide (DMF) at 70 °C 2 , MAI and BAI were stirred for 1 hour. Prepare Pb in this way 2+ The concentration is 0.9mol L -1 , 0.7mol L -1, 0.5mol L -1 , 0.3mol L -1 and 0.2mol L -1 The solution.

[0151] 2D perovskite (iso-BA) was prepared by 2 (MA) 4 Pb 5 I 16 Precursor solution: PbI with a molar ratio of 5:4:2 in dimethylformamide (DMF) at 70 °C 2 , MAI and isobutylammonium iodide (iso-BAI) were stirred for 1 hour. Prepare Pb in this way 2+ The concentration is 0.3mol L -1 The solution.

[0152] 2D perovskite (BA) was prepared by 2 (MA) 4 Pb 5 I 16 Precursor solution: PbI with a molar ratio of 5:4:2 in dimethylformamide (DMF) at 70 °C 2 , MAI and BAI were stirred for 1 hour. Prepare Pb in this way 2+ The concentration is 0.3molL -1 The solution.

[0153] 2D ...

Embodiment 2

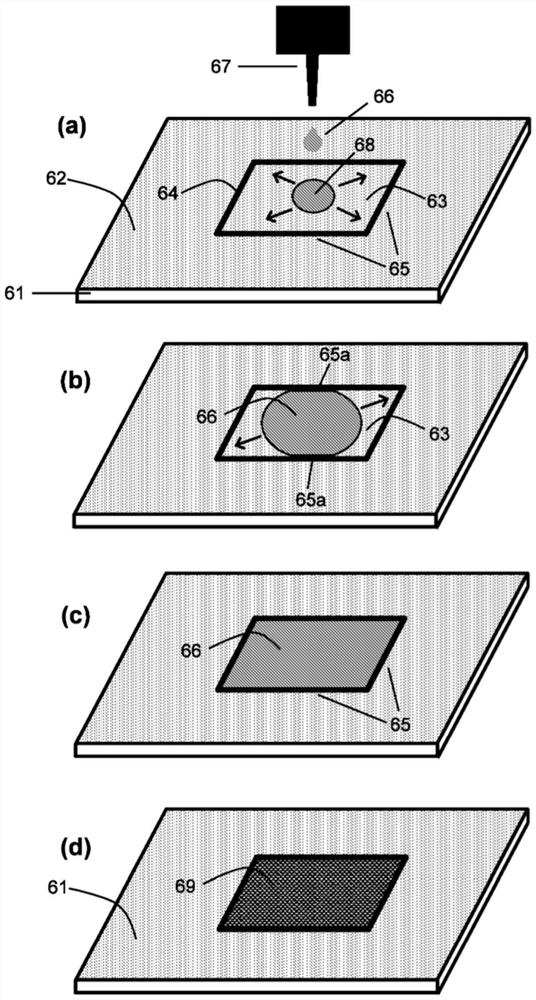

[0156] Example 2. Preparation of shaped 2D perovskite films on glass substrates

[0157] Use a size of 21G×1 1 / 4 A laboratory syringe needle, using an automatic pump to control the flow rate, draws a line of fluid composition onto the surface of an ITO glass substrate. The needle thus deposited a line of ink comprising the hydrophobic poly(triarylamine) (PTAA) polymer poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine on the substrate. The glass substrate has a hydrophilic surface characterized by a water contact angle of 36°±1.7. The water contact angle of PTAA exceeds 90° (about 105° reported in Nat Commun. 2015, 6, 7747). By drawing boundary lines on the surface of a hydrophilic substrate with a hydrophobic ink, it is possible to selectively cover shaped regions of the surface with a perovskite precursor solution by the following method.

[0158] The substrate was placed on a hot plate in air and heated to 50°C. Then Pb 2+ The concentration is 0.3mol L -1 of (BA) 2 (M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com