Preparation method of ferric oxide/spiral nano carbon fiber composite negative electrode material

A nano-carbon fiber, ferric oxide technology, applied in the direction of negative electrode, nanotechnology, nanotechnology, etc., can solve the problems of cumbersome and complicated process operation, potential safety hazards for experimenters, and inability to industrialize production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of ferric oxide / helical nano-carbon fiber composite negative electrode material, comprising the following steps:

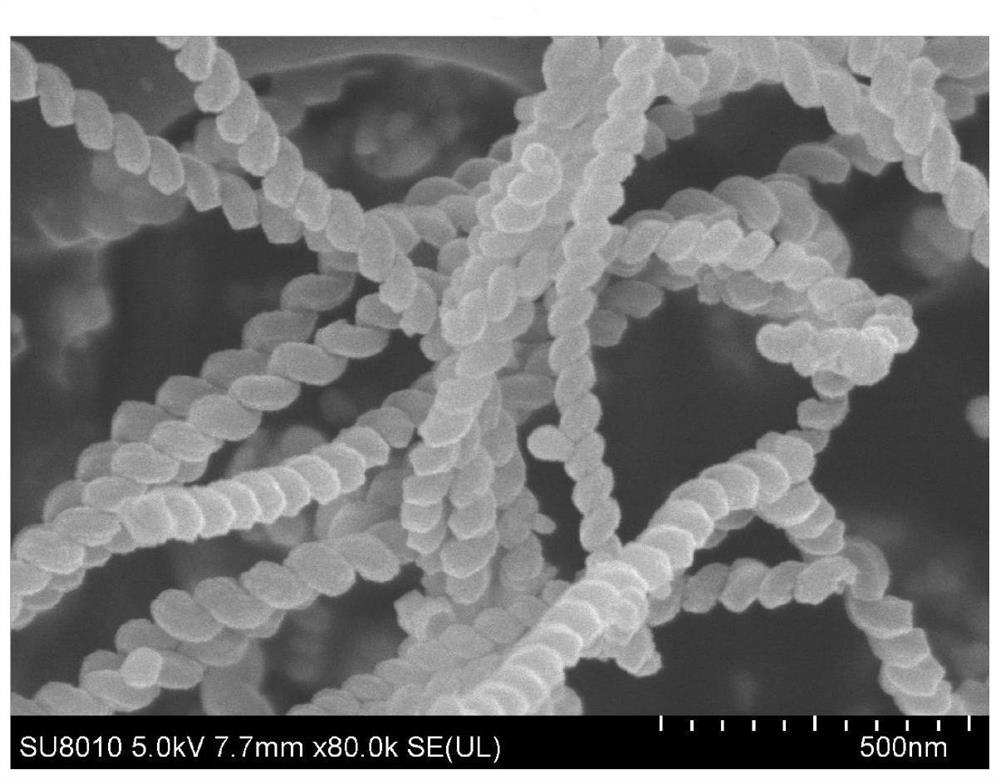

[0029] (1) Place the helical carbon nanofibers in a vacuum environment, and heat-treat at 700-900°C for 2-4 h, and set aside;

[0030] (2) Add the heat-treated helical carbon nanofibers into the mixture of water and ethanol, and obtain solution A after ultrasonic dispersion;

[0031] (3) Fe(NO 3 ) 3 •9H 2 O was added to solution A, and solution B was obtained after ultrasonic dispersion;

[0032] (4) Place solution B in an oil bath at 100-140°C for 4-6 hours, then filter and dry to obtain a solid reactant;

[0033] (5) Place the solid reactant obtained in step (4) in a tube furnace, then raise the temperature to 300-600 °C at a rate of 5-10 °C / min, and calcinate for 2-4 h to obtain the ferric oxide / Helical nano-carbon fiber composite anode material.

[0034] The invention adopts the helical nano-carbon fiber with a mass fraction ...

Embodiment 1

[0045] (1) Place the helical carbon nanofibers in a vacuum environment and heat-treat at 700 °C for 2 h, and set aside;

[0046] (2) Weigh 0.2 g of heat-treated helical carbon nanofibers and add them to a mixture containing 100 mL of water and 100 mL of ethanol, and ultrasonically disperse for 1 hour to obtain solution A;

[0047] (3) Weigh 1.6 g Fe(NO 3 ) 3 •9H 2 O was added to solution A, and solution B was obtained after ultrasonic dispersion for 10 minutes;

[0048] (4) Pour solution B into a 250 ml round bottom flask, and put it in an oil bath at 120 °C for 4 h. The product was suction filtered and dried at 80 °C for 12 h to obtain a solid reactant;

[0049] (5) Put the solid reactant obtained in step (4) in a corundum boat and place it in the middle of the tube furnace, then raise the temperature to 350°C at a rate of 5°C / min, and calcinate for 2 hours to obtain the Iron / helical nano-carbon fiber composite anode material.

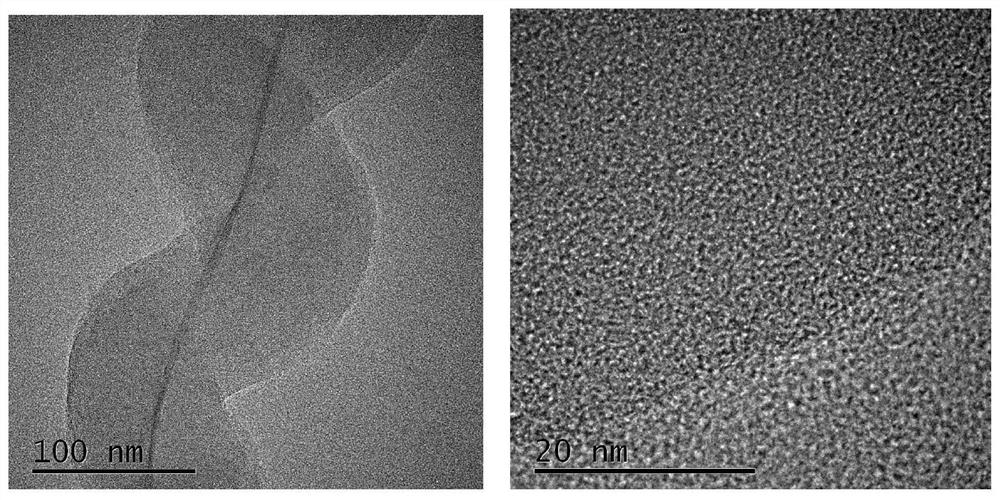

[0050] In this embodiment, the electron m...

Embodiment 2

[0055] (1) Place the helical carbon nanofibers in a vacuum environment and heat-treat at 700 °C for 2 h, and set aside;

[0056] (2) Weigh 0.2 g of heat-treated helical carbon nanofibers and add them to a mixture containing 100 mL of water and 100 mL of ethanol, and ultrasonically disperse for 1 hour to obtain solution A;

[0057] (3) Weigh 2.0 g Fe(NO 3 ) 3 •9H 2 O was added to solution A, and solution B was obtained after ultrasonic dispersion for 10 minutes;

[0058] (4) Pour solution B into a 250 ml round bottom flask, and put it in an oil bath at 120 °C for 4 h. The product was suction filtered and dried at 80 °C for 12 h to obtain a solid reactant;

[0059] (5) Put the solid reactant obtained in step (4) in a corundum boat and place it in the middle of the tube furnace, then raise the temperature to 350°C at a rate of 5°C / min, and calcinate for 2 hours to obtain the Iron / helical nano-carbon fiber composite anode material.

[0060] The method in Example 1 was used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First charge and discharge capacity | aaaaa | aaaaa |

| First charge and discharge capacity | aaaaa | aaaaa |

| First charge and discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com