Unlimited-grade well cementation sliding sleeve for preventing cement solidification and assembling and operating method thereof

An infinite level, cement technology, applied in wellbore/well valve device, earthwork drilling, wellbore/well components, etc., can solve the problems of reducing the number of applications of cementing sliding sleeves, cumbersome, and reducing perforation operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

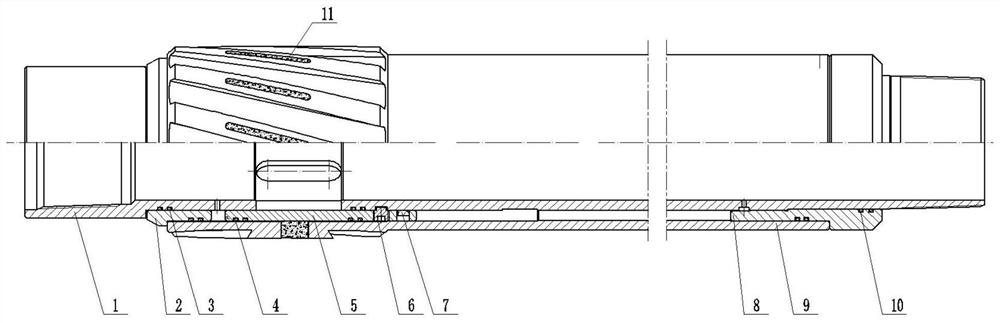

[0043]An infinity-level well-formed slide jacket that prevents cement consolidation, from central tube 1, upper positioning ring 2, first O-ring 3, second O-ring 4, piston sleeve 5, shear 6, lock ring 7, The lower positioning ring 8, the outer casing 9, the third O-ring 10, the solid fat 11, and the mounting nail 12 are composed.

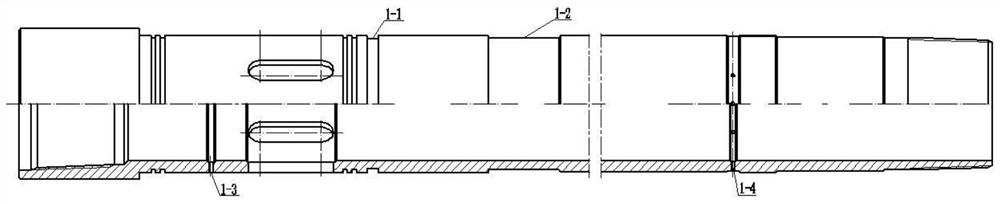

[0044]The center of the center tube 1 is the mother thread connected to the sleeve, the right diameter of the mother thread is the sealing surface, the female thread and the sealing surface transition passing 45 degrees, so as not to scratch the internal rubber member, the center tube 1 outermost side The surface is a clamping surface, which can be clamped and solid well. The right side of the clamping surface is the sealing surface, the outer diameter of the sealing surface is smaller than the outer diameter of the clamping surface, thereby forming a step, the sealing surface is from left to the left, respectively, two O 6 long elliptical holes and other tw...

Embodiment 2

[0050]An assembly process for preventing cement-consolidated infinite solid wells:

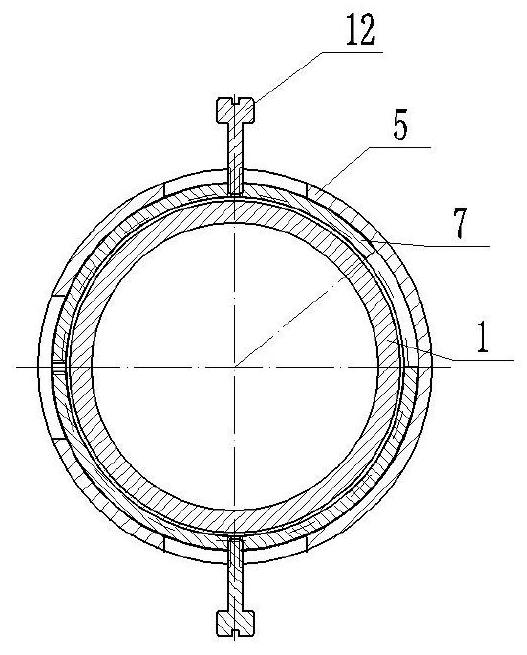

[0051]In the assembly process, the lock ring 7 is prejected into the piston sleeve 5, and then the piston sleeve 5 is set together from the center tube 1 to the right side of the center tube 1, and the lock ring 7 enters into the center tube during the kit 7 1 When the outer lock ring limit slot 1-2, the lock ring 7 will shrink, so that the straight step is blocked by the left side, and the assembly cannot be continued. At this time, 2 mounting nail 12 need to be loaded into the lock ring 7 thread. During the hole, such asfigure 2 , Then need two people to cooperate, one person uses two hands to do the nail 12, forcing the outer diameter of the lock ring 7, when the lock ring 7 is much larger than the outer diameter of the left straight step of the lock ring limit slot 1-2 The lock ring 7 and the piston sleeve 5 can pass the straight steps and assembled, and the assembly of other components is conventi...

Embodiment 3

[0053]An open process for preventing cement-consolidated infinite solid well slide

[0054]The present invention is connected to the sleeve, and the number is the same as the number of segments to be fractured. The number of segments of each pressure fracturing corresponds to one of the present invention. When it is below a predetermined position, the internal service tool, the internal service tool has bottom. The packer, the bottom packer is seal between the transfer ports 1-3 and the balance holes 1-4, and the hydraulic pressure in the present invention, the piston sleeve 5 is moving toward the right, when the liquid pressure The shear value of the shear nice 6 is reached, and the shear 6 is cut, the piston sleeve 5 is moved to the right, and the piston sleeve 5 reaches the maximum displacement through the bevel 9 in the outer casing 9. At this time, the lock ring inside the piston sleeve 5 The lock ring limit groove 1-2 in the outer side of the center tube 1 is inserted, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com