drag packer

A packer and sealing mechanism technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problem of packer being stuck by sand, so as to ensure the sealing performance and anti-high pressure performance , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a dragging packer. The up and down positions described herein are for the use state of the dragging packer after entering the oil well. To be precise, the dragging packer The connector position of the device is down.

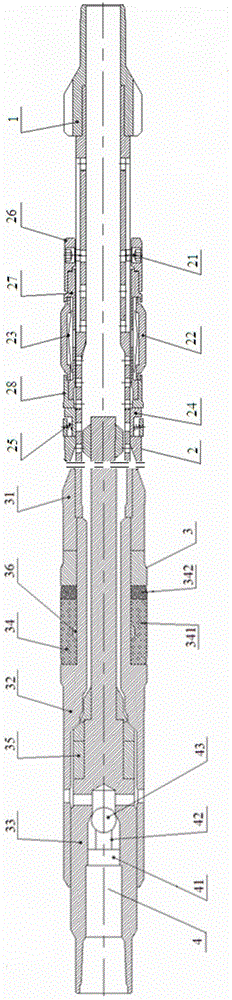

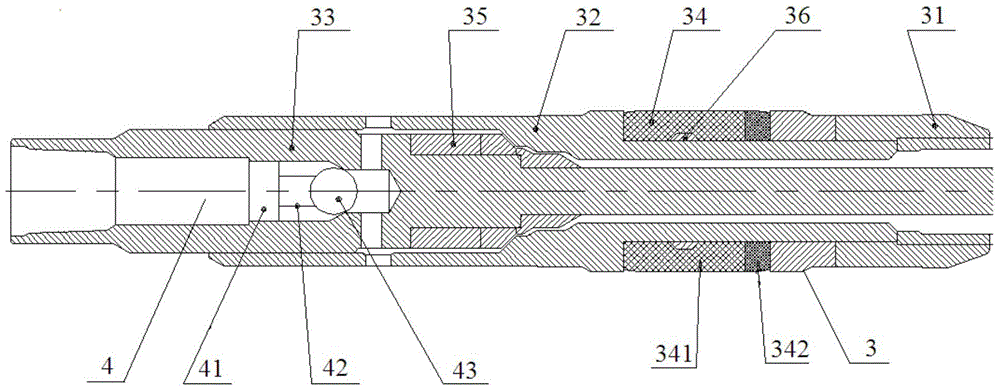

[0024] The structure of the dragging packer is as follows: Figure 1-Figure 3 As shown, it includes a joint 1 , a reversing mechanism 2 and a sealing mechanism 3 connected sequentially from bottom to top.

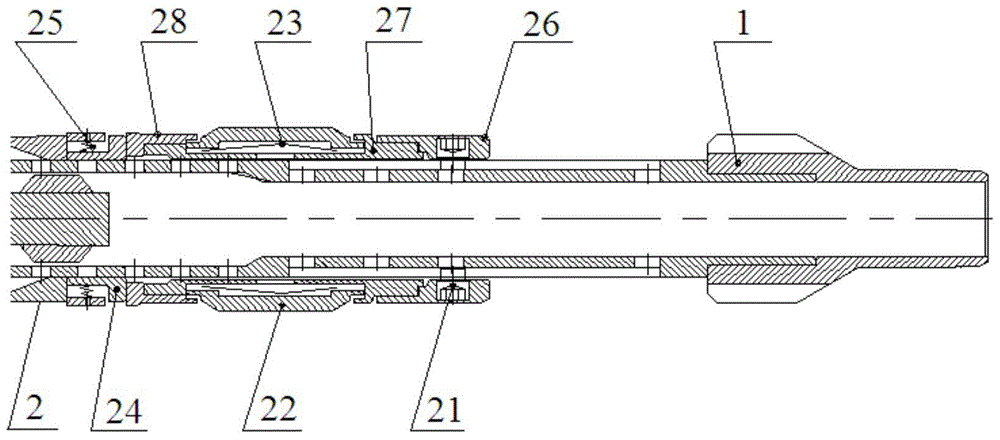

[0025] Such as image 3 As shown, the reversing mechanism 2 includes a guide head 21, a righting block 22, a righting block spring 23, a slip 24 and a slip spring 25, the guide head 21 is threaded on the guide head seat 26, the righting block 22 and the righting block spring 23 Installed on the righting block seat 27, the guide head seat 26 and the righting block seat 27 are threaded, the slips 24 and the slip spring 25 are installed on the slip seat 28, and the slip seat 28 and the righting block seat 27 are threaded, the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com