Wellhead water-mixing combination valve of oil production well

A technology for oil production wells and combined valves, which is applied to valve devices of wellbore/well, wellbore/well components, and earth-moving drilling and production, etc., can solve problems such as cost increase, pipeline freezing, combination, etc. The effect of slowing down the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

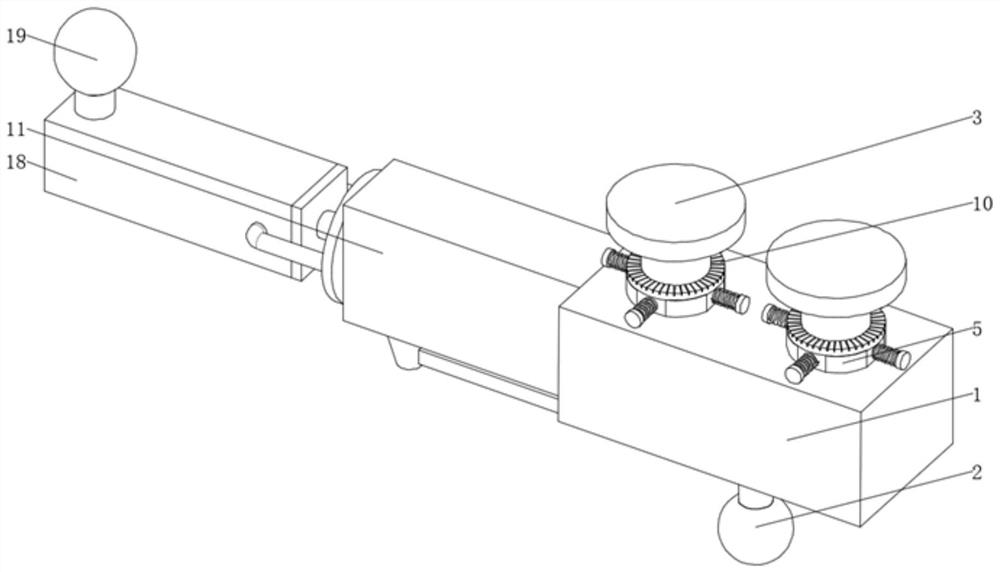

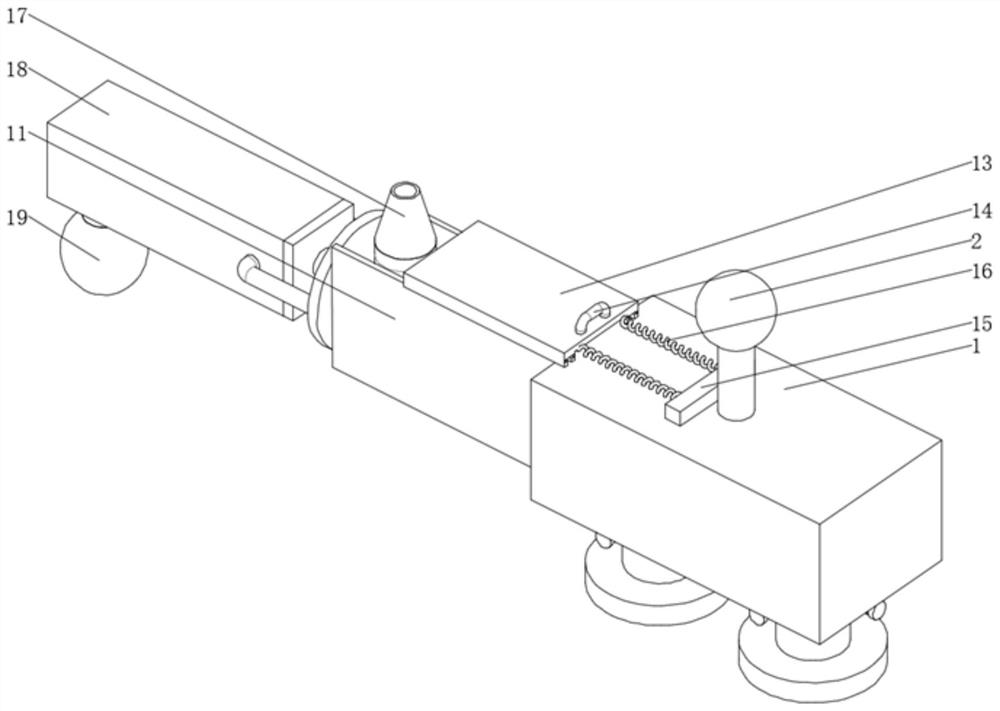

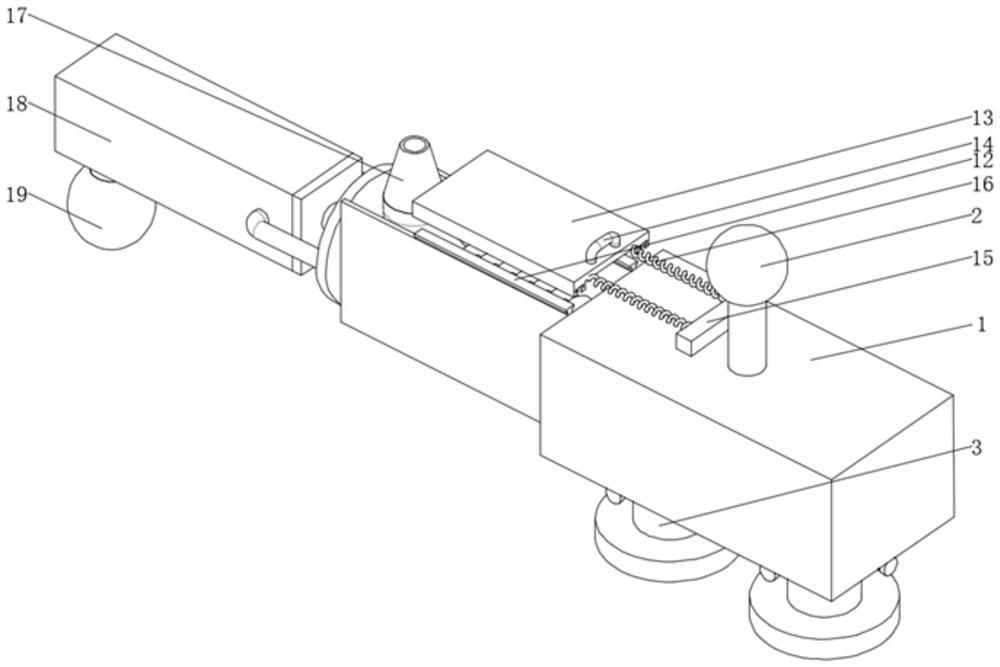

[0027]SeeFigure 1-7An oil absorbing well port is blended in combination valve, including the valve body 1, the left end fixation communication with the valve body 1, and the left end of the valve body 1 is fixedly mounted with a protective shell 11 on the outer side of the retorium pipe 17, the protective case 11 The left end fixation is mounted with a touched switch 23. The left end of the tap switch 23 is provided with a sealing sleeve 18. The top end of the sealing sleeve 18 is fixedly connected with the airbag 19, and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com