A kind of film with high luminous intensity, preparation method and use thereof

A technology of thin film preparation and luminous intensity, which is applied in the field of chemical modification, can solve the problems of randomness in the enhancement area, insignificant enhancement effect, and long preparation cycle, and achieve the effects of short preparation cycle, low cost and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

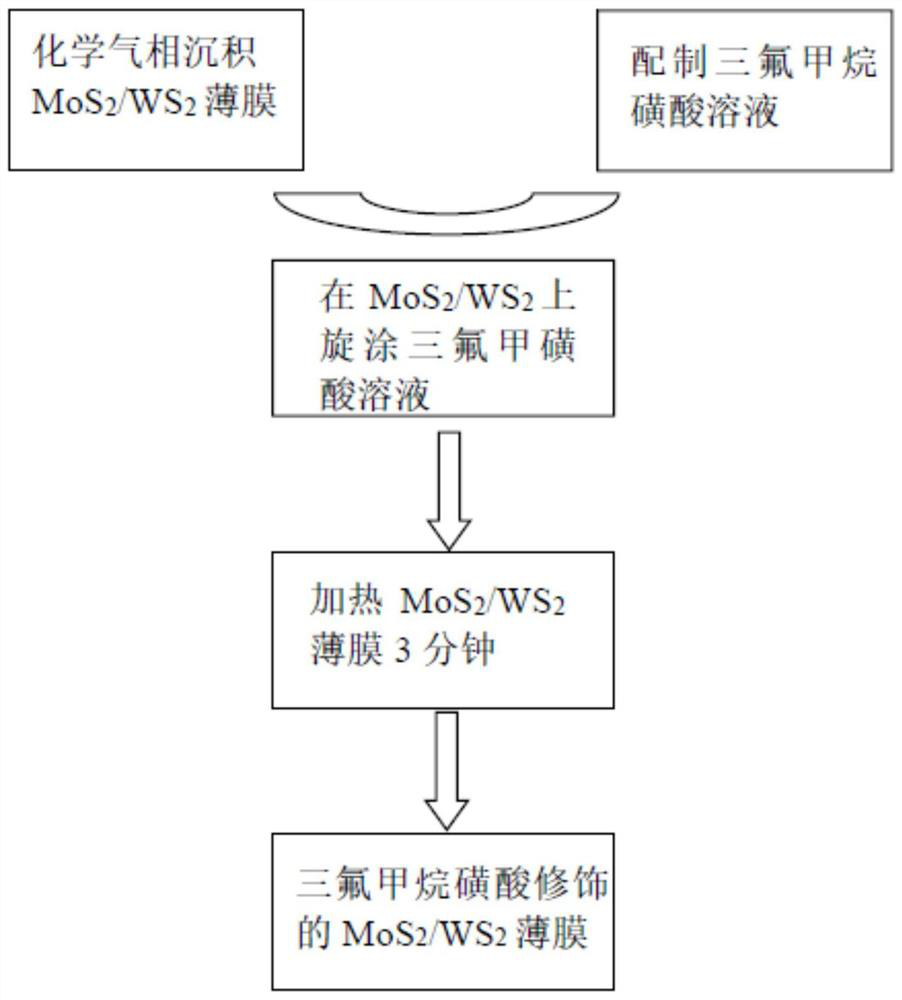

[0049] The preparation process flow diagram of Example 1 can be referred to figure 1 , figure 1 It is a process flow diagram of the thin film preparation method of the present invention.

[0050] like figure 1 As shown, the film preparation method includes the following steps:

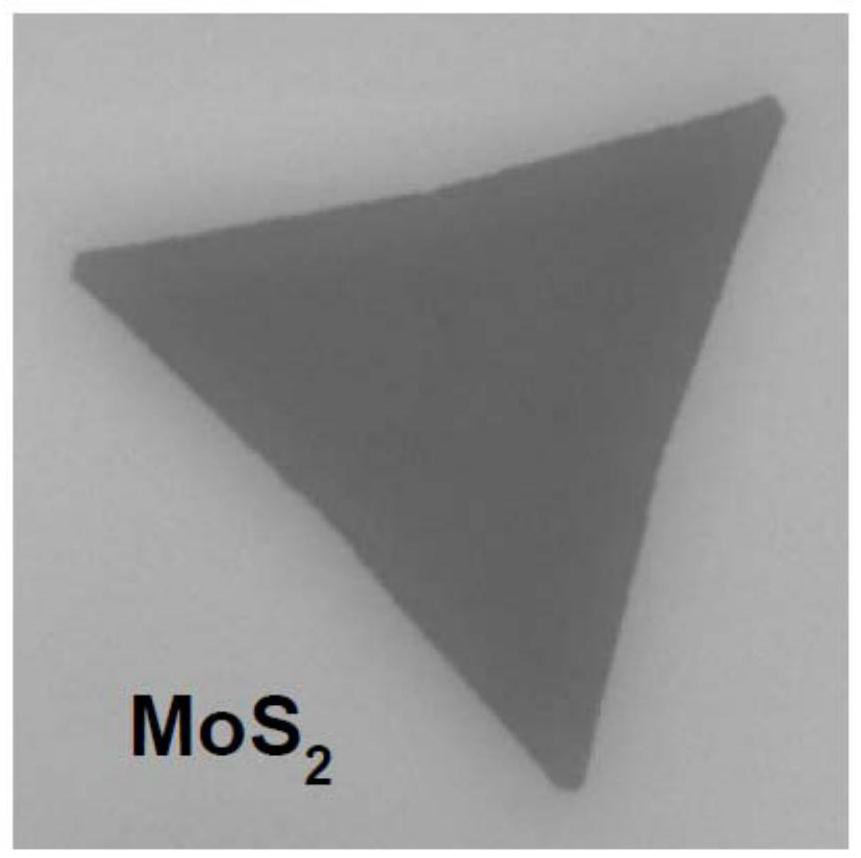

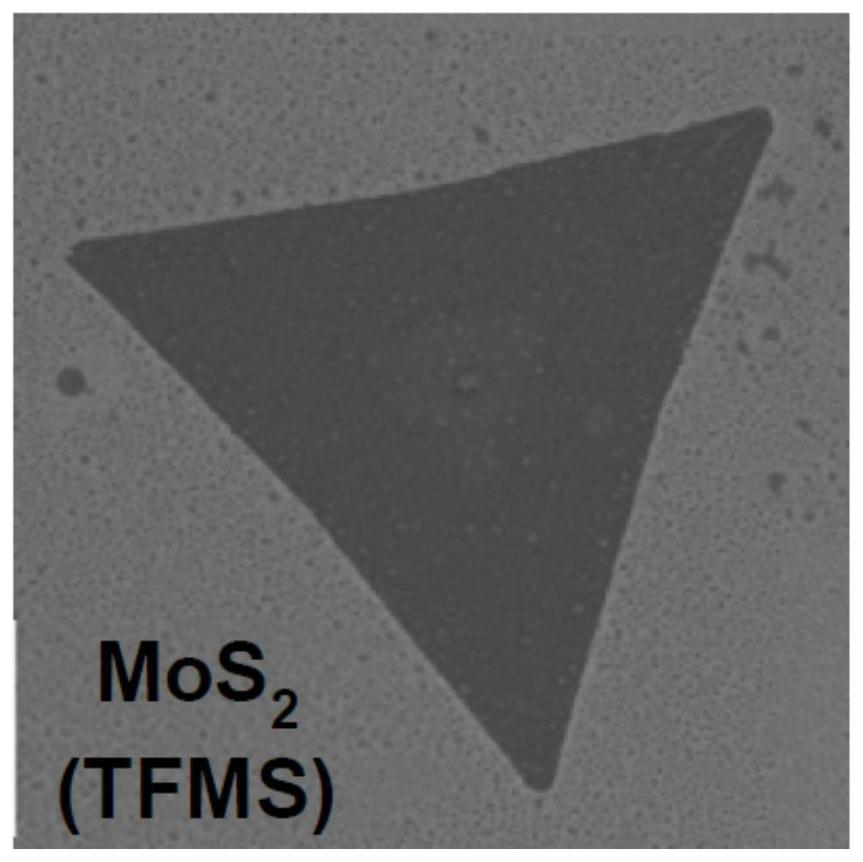

[0051] Step 1: Preparation of molybdenum disulfide: using sulfur powder and molybdenum trioxide powder as raw materials, wherein, sulfur powder (product source: Sigma-Aldrich, 99.99%, 500mg) and molybdenum trioxide powder (product source: Sigma-Aldrich, 99.98%, 5mg), sulfur powder and molybdenum trioxide powder were placed in the upstream and central positions of the tube furnace respectively with a distance of 31cm, the substrate was placed 2cm downstream of the molybdenum trioxide powder, and then passed through chemical vapor Deposition method (wherein, the process adopted by chemical vapor deposition method can be conventional process means, for example, the heating temperature is 850 ° C) to ob...

Embodiment 2

[0060] The preparation process flow chart of embodiment 2 can refer to figure 1 , figure 1 It is a process flow diagram of the thin film preparation method of the present invention.

[0061] like figure 1 As shown, the film preparation method includes the following steps:

[0062] Step 1: Preparation of tungsten disulfide: using sulfur powder and tungsten oxide powder as raw materials, wherein, sulfur powder (product source is Sigma-Aldrich, 99.99%, 1g) and tungsten trioxide powder (product source is Sigma-Aldrich, 99.98% , 5mg) were placed in two quartz boats, and 15mg of sodium chloride powder was added to the tungsten trioxide powder as a flux. The sulfur powder was placed in the center of the low temperature zone of the tube furnace, 55 cm away from the tungsten trioxide powder placed in the center of the high temperature zone of the tube furnace. Then, the substrate is placed downstream of the tungsten trioxide powder at a distance of 0.5 cm, and then a single-layered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com