Melt-blown polypropylene material as well as preparation method and application thereof

A technology of melt-blown polypropylene and polypropylene, applied in the field of modified polypropylene, which can solve problems such as unstable adsorption of peroxide, collapse of cells, and high cost of dual-functional masterbatches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

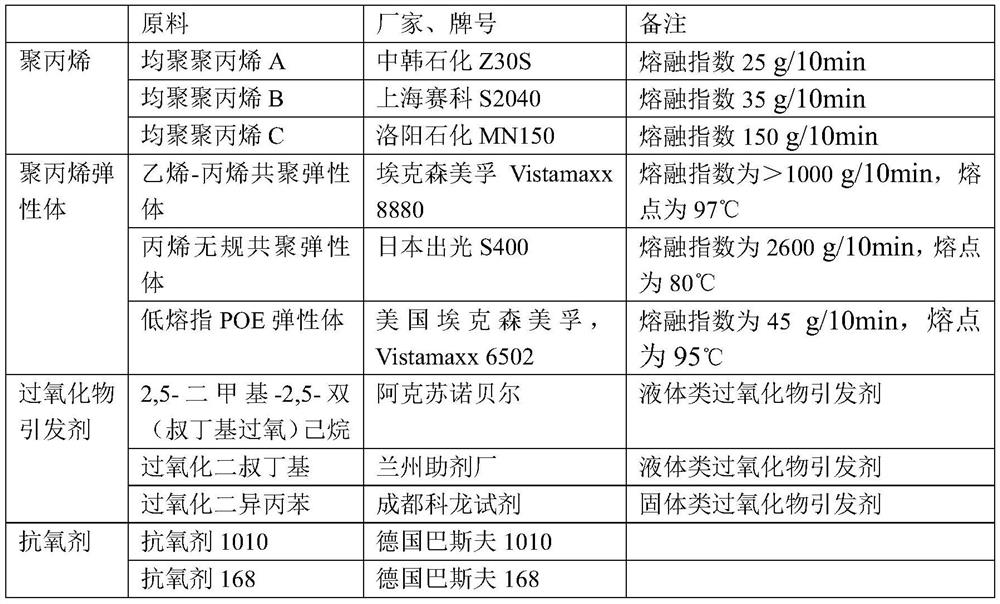

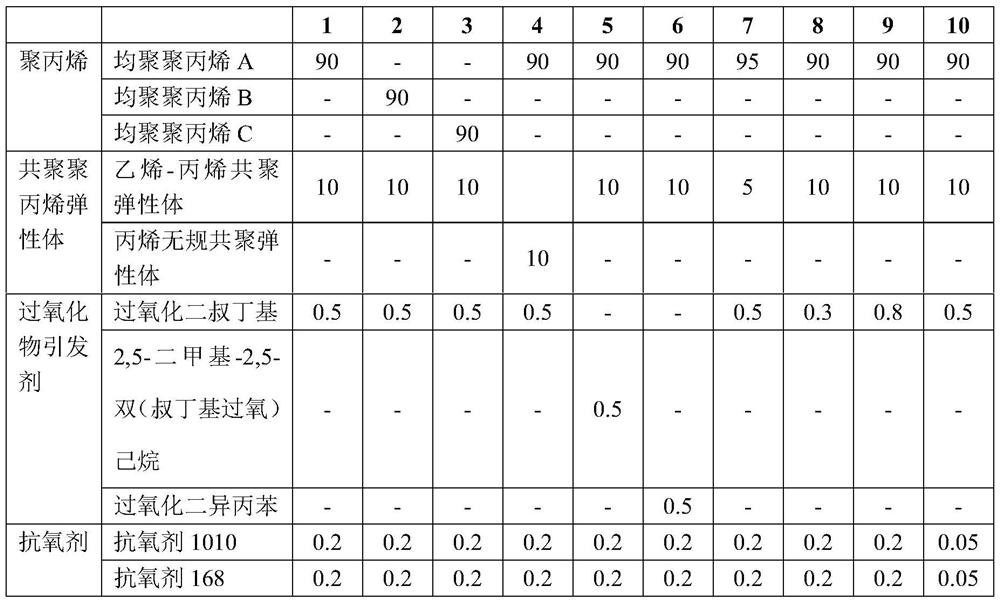

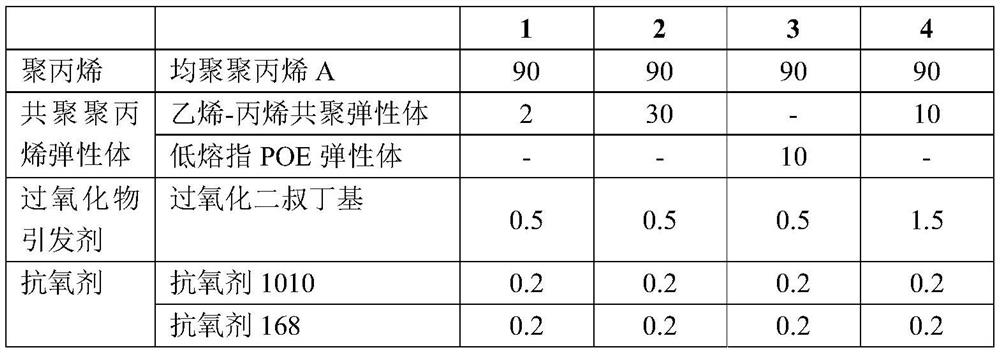

[0049] See Table 1 for the content of each component of the melt-blown polypropylene material in Examples 1-10.

[0050] Its preparation method is:

[0051] S1. Stir and blend the peroxide initiator, copolymerized polypropylene elastomer, and antioxidant at 80-120°C under the protection of an inert gas, and prepare the peroxide masterbatch through underwater granulation;

[0052] S2. After mixing the peroxide masterbatch and polypropylene, add them to a twin-screw extruder, and melt and granulate to obtain a melt-blown polypropylene material.

[0053] The screw length-to-diameter ratio of the twin-screw extruder is 48:1~64:1, the extrusion temperature is 180~250°C, and the screw speed is 200~500rpm. Underwater granulation is to melt and mix peroxide initiator, copolymerized polypropylene elastomer, and antioxidant, scrape off by blades in the melt state, and solidify into particles after cooling by circulating water, which is used for underwater granulation The equipment is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com