Method for aqueous two-phase extraction, separation and purification of dendrobium officinale polysaccharide

A technology for the separation and purification of Dendrobium officinale polysaccharides, which is applied in the field of extraction, can solve the problems of multiple repetitions, high loss rate of polysaccharides, complicated operation, etc., and achieve the effects of improved purity, safe extraction, and improved polysaccharide extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

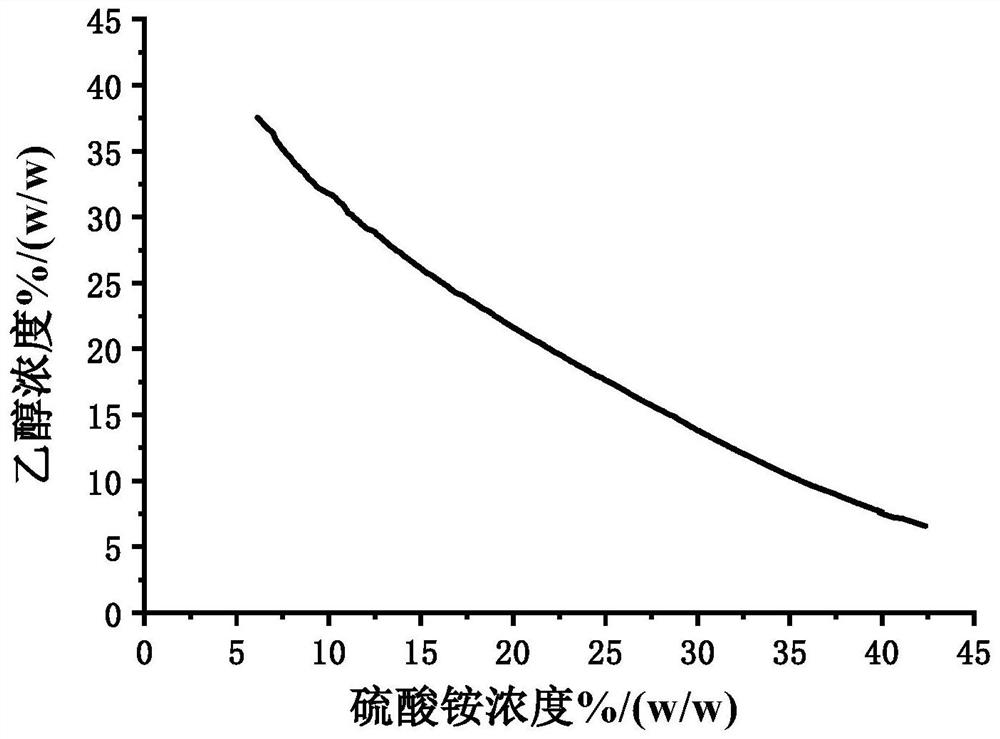

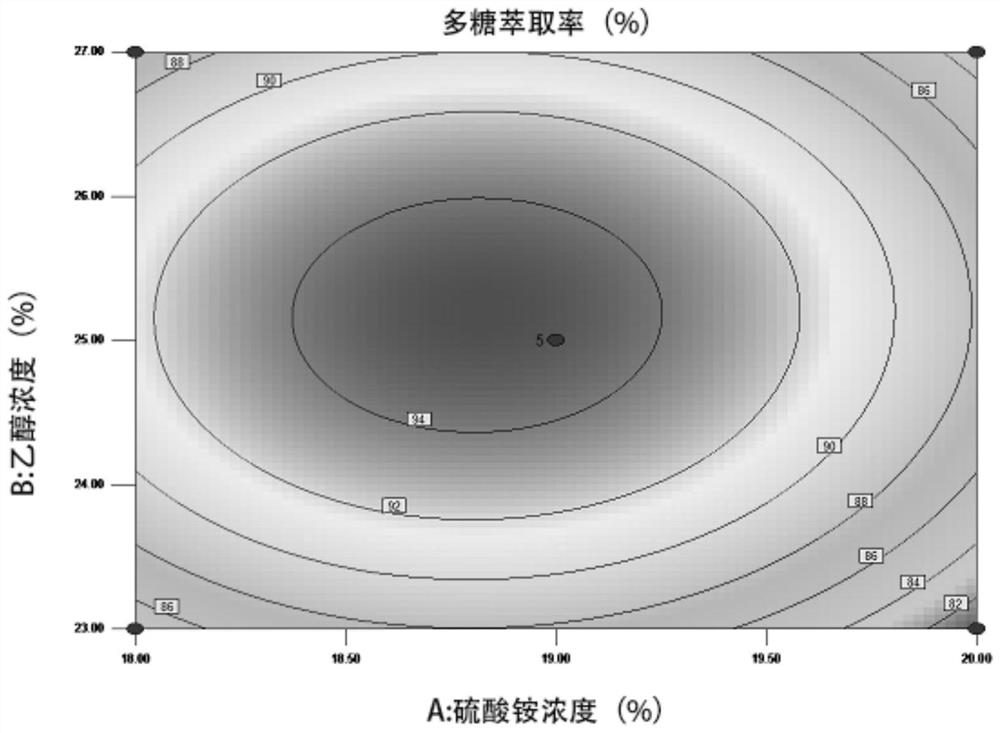

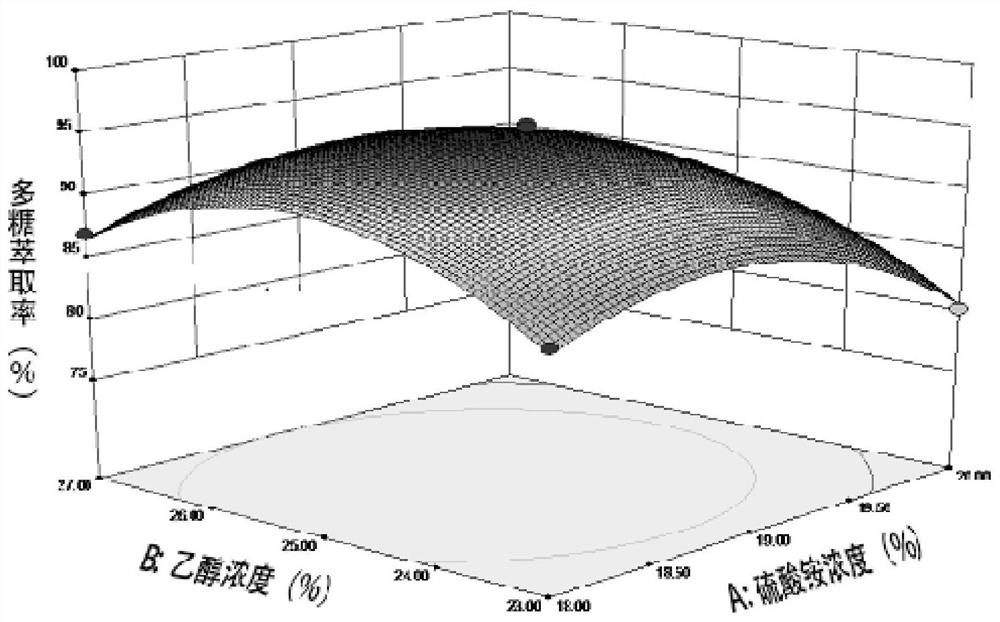

Embodiment 1

[0032] (1) A method for separating and purifying the polysaccharides of Dendrobium officinale by two-phase extraction, drying the fresh stems of Dendrobium officinale at 50°C, and pulverizing them to 200 mesh with a traditional Chinese medicine pulverizer; accurately weighing 10.0g of Dendrobium officinale powder, according to 1:25 feed solution Add 250mL of deionized water to the mass volume ratio, stir well; keep the solution temperature at 55-60°C, extract twice, each time for 1h; combine the two extracts, filter with gauze, centrifuge at 7500r / min for 10min, and take the supernatant The clarified extract was obtained, concentrated to 30mL with a rotary evaporator at 60°C, then added 120mL of 95% ethanol, shaken well, refrigerated at 4°C for 12h, taken out and centrifuged at 5000r / min for 15min, discarded the supernatant and left the precipitate, and the precipitate Freeze-drying was carried out for 2 days, and the white solid was ground to obtain a crude polysaccharide powd...

Embodiment 2

[0036] (1) A method for separating and purifying the polysaccharides of Dendrobium officinale by two-phase extraction, drying the fresh stems of Dendrobium officinale at 50°C, and pulverizing them to 200 mesh with a traditional Chinese medicine pulverizer; accurately weighing 10.0g of Dendrobium officinale powder, and mixing it according to the ratio of 1:20 feed solution Add 250mL of deionized water and stir evenly; keep the temperature of the solution at 60°C, extract twice, 1h each time; combine the two extracts, filter with gauze, centrifuge at 7500r / min for 10min, and take the supernatant to obtain clarification Concentrate the extract to 30mL with a rotary evaporator at 60°C, then add 120mL of 95% ethanol, shake well, refrigerate at 4°C for 12h, take it out and centrifuge at 5000r / min for 15min, discard the supernatant to save the precipitate, and freeze the precipitate After drying for 2 days, the white solid was ground to obtain a crude polysaccharide powder. The crude...

Embodiment 3

[0040] (1) A method for separating and purifying the polysaccharides of Dendrobium officinale by two-phase extraction, drying the fresh stems of Dendrobium officinale at 50°C, and pulverizing them to 200 mesh with a traditional Chinese medicine pulverizer; accurately weighing 10.0 g of Dendrobium officinale powder, and feeding it according to the ratio of 1:30 feed solution Add 250mL of deionized water and stir evenly; keep the solution temperature at 55°C, extract twice, 1h each time; combine the two extracts, filter with gauze, centrifuge at 7500r / min for 10min, and take the supernatant to obtain clarification Concentrate the extract to 30mL with a rotary evaporator at 60°C, then add 120mL of 95% ethanol, shake well, refrigerate at 4°C for 12h, take it out and centrifuge at 5000r / min for 15min, discard the supernatant to save the precipitate, and freeze the precipitate After drying for 2 days, the white solid was ground to obtain a crude polysaccharide powder. The crude poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com