Semi-synthesis method of morin

A semi-synthetic technology of Morin, which is applied in the direction of organic chemistry, can solve the problems of low yield, limited raw materials, and low content of Morin, and achieve high yield and simple and easy-to-operate process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 20 grams of dihydromorphin dry product, 150 grams of purified water and 0.8 grams of sodium hydroxide into a 250 ml reaction bottle, heat up and stir, and feed in oxygen. After the temperature reaches 95°C, time the reaction for 5 hours and then detect the raw material dihydrophyllin by liquid phase. If the remaining phyllin is less than 1%, the reaction is stopped to obtain a reaction solution containing morphin;

[0027] After cooling the reaction solution containing Morphein to room temperature, dilute hydrochloric acid was added to neutralize the reaction solution until it was neutralized, and then suction filtered to obtain 39 grams of the wet crude product of Morin.

[0028] Dissolve 39 grams of the crude product of Morinin in 100 grams of ethanol and recrystallize it to obtain 15 grams of Morinin fine product. The liquid phase detection content of Morinin fine product is 98.12%, and the yield of Morinin fine product is 75%.

Embodiment 2

[0030] Put 30 grams of dihydromorphin dry product, 210 grams of purified water and 1.05 grams of sodium hydroxide into a 500 ml reaction bottle, heat up and stir, and feed in oxygen. After the temperature reaches 95 ° C, time the reaction for 5 hours, and then liquid phase detection of raw material dihydrophyllin If the remaining phyllin is less than 1%, the reaction is stopped to obtain a reaction solution containing morphin;

[0031] After cooling the reaction solution containing Morphein to room temperature, dilute hydrochloric acid was added to neutralize the reaction solution until it was neutralized, and then suction filtered to obtain 61 grams of the wet crude product of Morin.

[0032] Dissolving 61 grams of the crude product of Morinin in 150 grams of ethanol and recrystallizing to obtain 21 grams of Morinin fine product, the liquid phase detection content of Morinin fine product was 97.89%, and the yield of Morinin fine product was 70%.

Embodiment 3

[0034] 50 grams of dihydromorin dry product, 300 grams of purified water and 1.5 grams of sodium hydroxide are dropped into 500 milliliters of reaction flasks and are heated and stirred and fed into oxygen, such as figure 1 As shown, after the temperature reached 95°C, the timing reaction was performed for 6 hours, and the liquid phase detection of the raw material dihydromorin was less than 1%, and the reaction was stopped, and the reaction solution containing morin was obtained;

[0035] After cooling the reaction liquid containing morin to room temperature, dilute hydrochloric acid was added to neutralize the reaction liquid to neutrality, and then suction filtered to obtain 98 grams of wet crude product of morin, and the yield of refined morin was 70-74%.

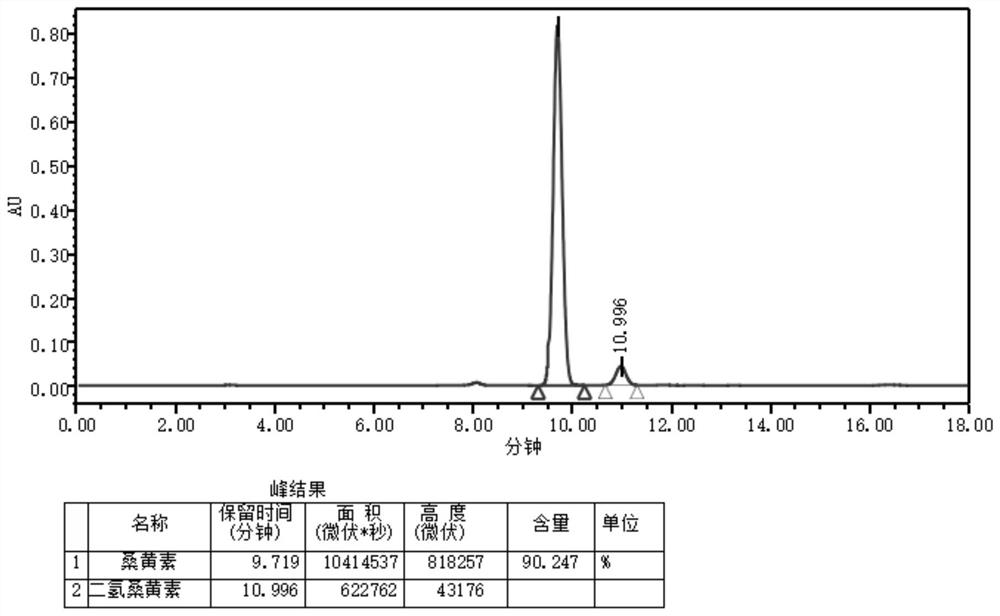

[0036] After 98 grams of the crude product of Morin are dissolved in 250 grams of ethanol and recrystallized, 36 grams of the fine product of Morin are obtained, as figure 2 As shown, the liquid phase detection content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com