Laser-microwave composite deicing system and method

A laser and microwave technology, applied in the field of laser applications, can solve problems such as normal operation of high-voltage wires affecting blade life, icing of fan blades and high-voltage wires, safety hazards of units and on-site personnel, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to make the techniques, creative characteristics, objective and efficacy of the present invention, which will be further illustrated in connection with the accompanying drawings and specific embodiments.

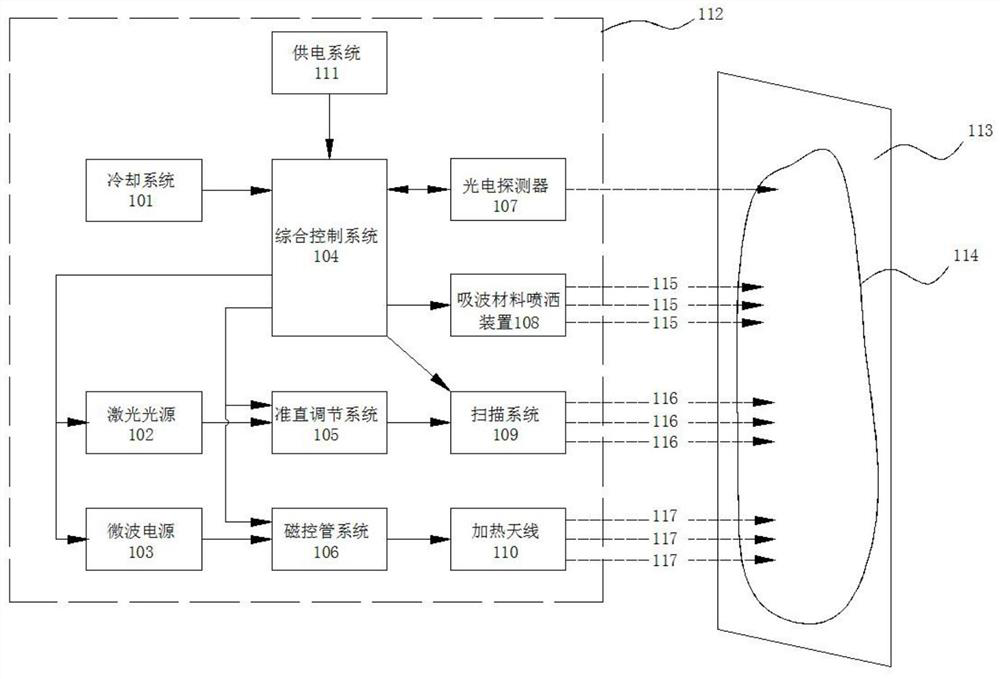

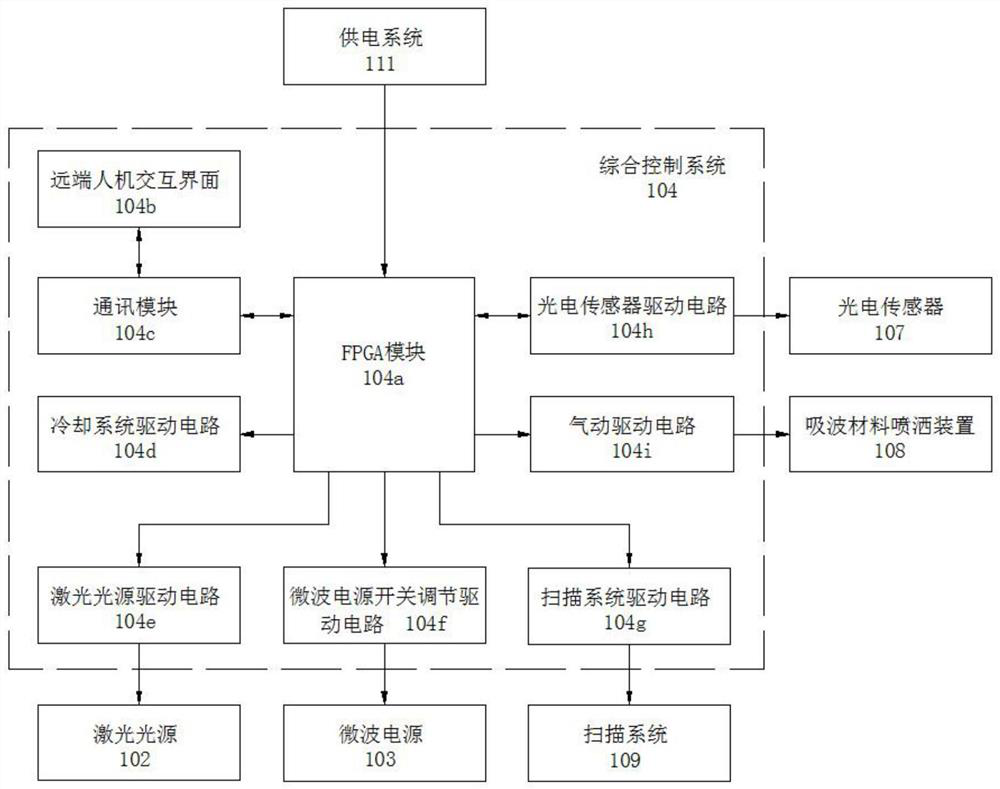

[0049]Seefigure 1 As shown, the laser-microwave composite de-ice system provided by the present invention includes a cooling system 101, a laser light source 102, a microwave power source 103, a composite control system 104, a collimator adjustment system 105, a magnetron system 106, and a photoelectric sensor 107. , The absorbing material spraying device 108, the scanning system 109, and the heating antenna 110, the integrated control system 105 respectively corresponds to the cooling system 101, a laser light source 102, a microwave power source 103, a collimation adjustment system 106, a magnetron system 106, a photoelectric sensor 107, The absorbing material spraying device 108 and the scanning system 109 are electrically connected;

[0050]Wherein, the cooling system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com