A thermal barrier coating service life measuring and calculating method and device

A technology of thermal barrier coating and life prediction model, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve problems such as inaccurate results and inability to achieve self-calibration and self-correction of algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

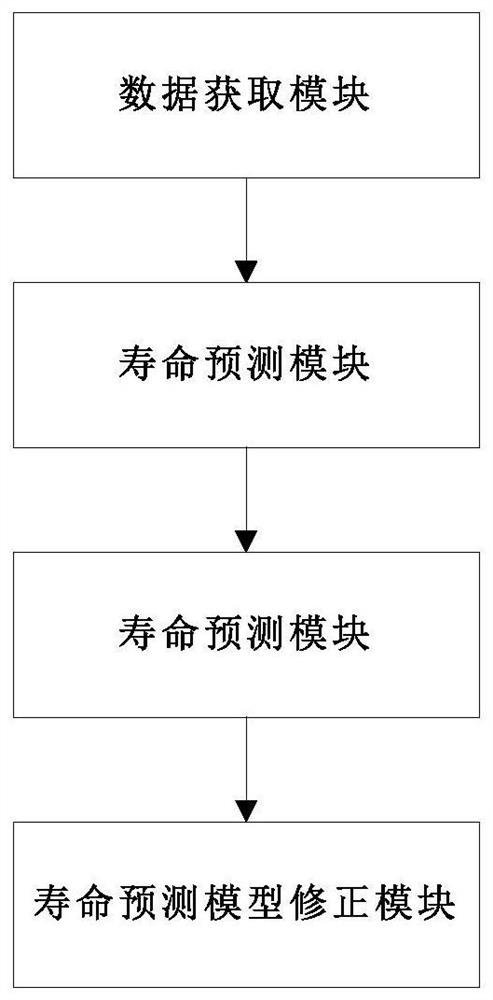

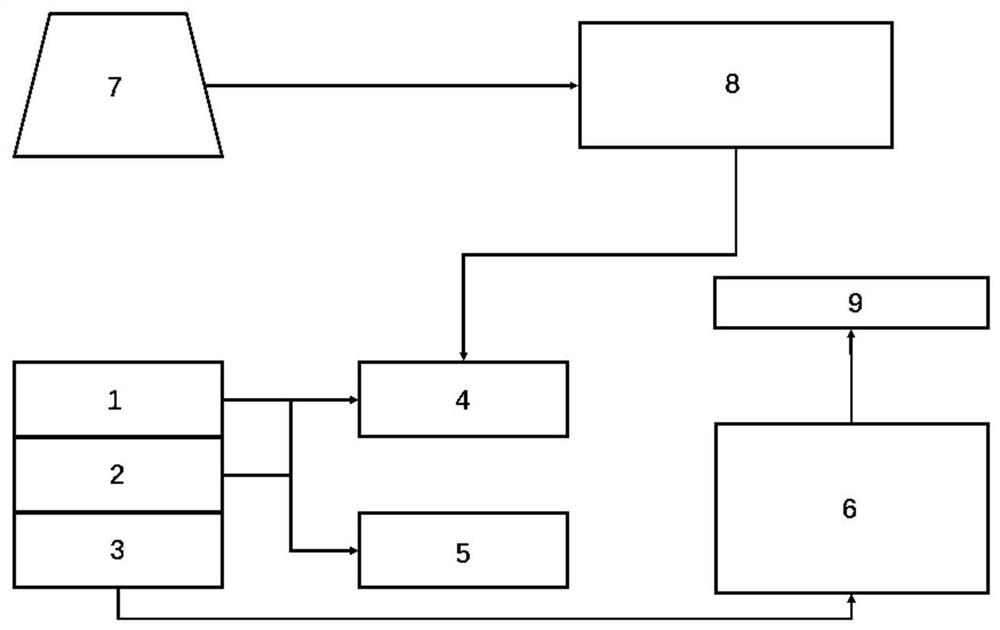

[0037] Such as figure 1 As shown, a thermal barrier coating life measurement equipment, including:

[0038] The data acquisition module acquires the user's historical use data, the component structure information of the thermal barrier coating, and the planned use condition of the component;

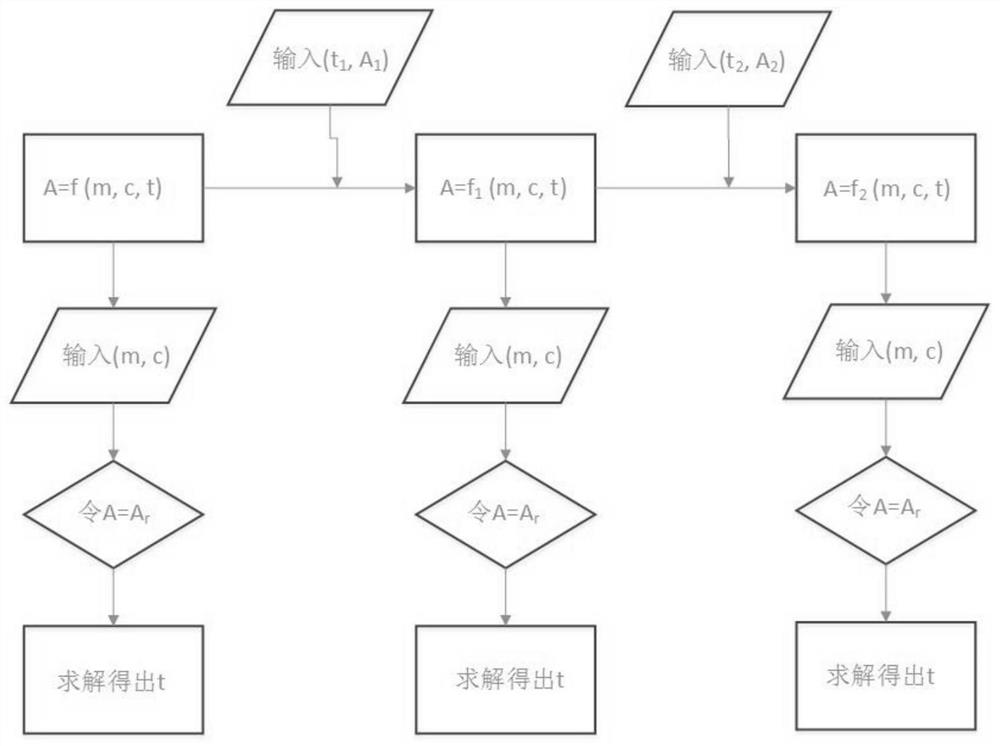

[0039] The life prediction module obtains the life prediction model of the thermal barrier coating according to the obtained user historical use data, the component structure information of the thermal barrier coating, and the planned operating conditions of the components;

[0040] The non-destructive testing module measures the microstructural damage factor of thermal barrier coatings;

[0041] The life prediction model correction module corrects the fitting coefficient of the life prediction model through the measured microstructure damage factor of the thermal barrier coating, obtains the corrected life prediction model, and obtains the life of the thermal barrier coating.

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com