Method for treating vanadium-containing waste catalyst

A waste catalyst, sodiumization technology, applied in the direction of improving process efficiency, etc., can solve the problems of reducing the leaching rate of sodiumized clinker, affecting the conversion rate of soluble sodium salt, vanadium wrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

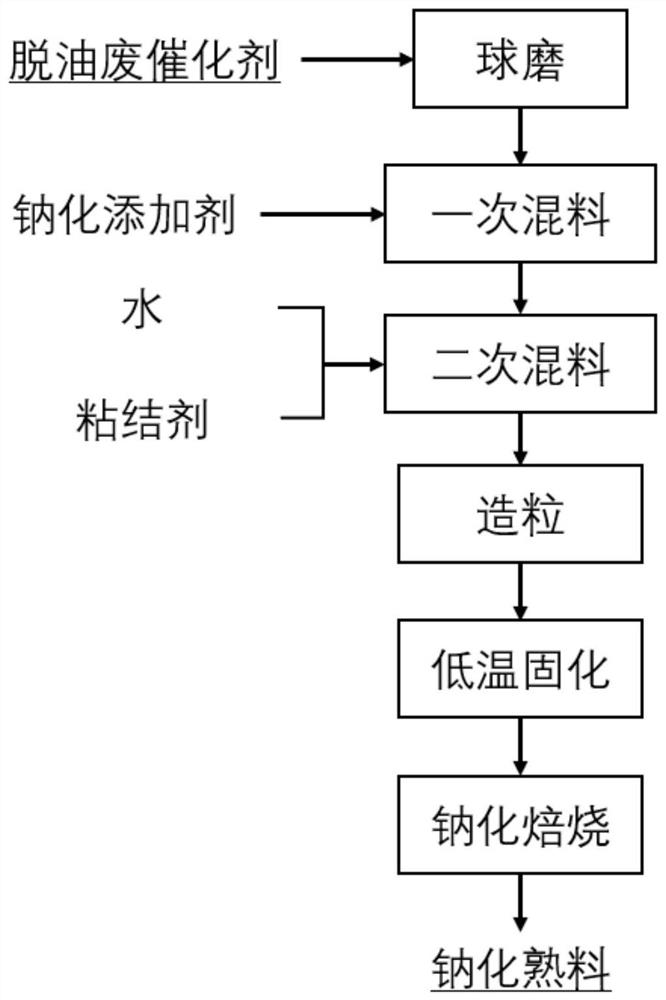

Method used

Image

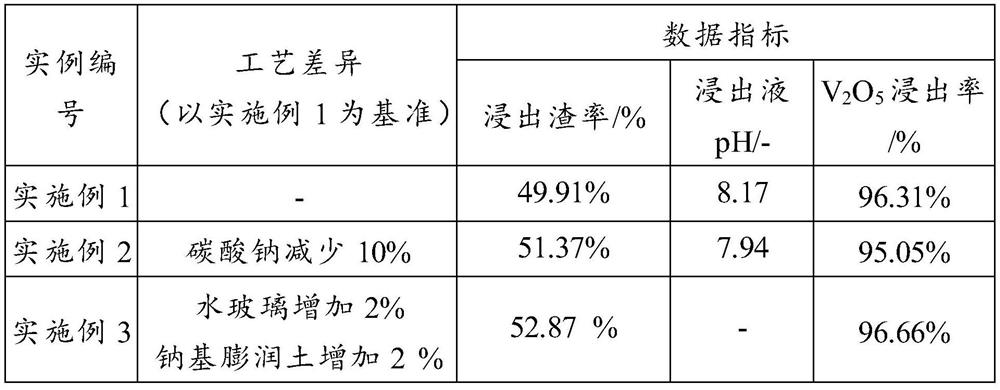

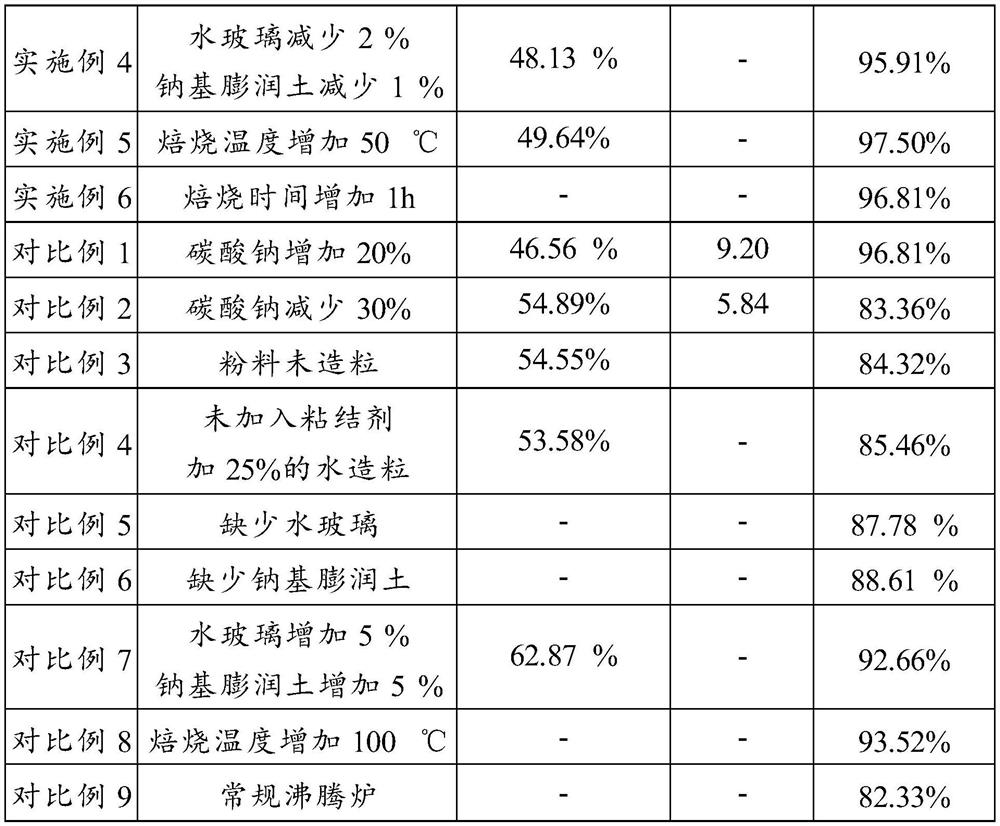

Examples

Embodiment 1

[0036] (1) Get 500kg of deoiled vanadium-containing waste catalyst, the original material is columnar particles, the length is 5-15mm, and the raw material composition is as shown in Table 1; the raw material is put into high-energy ball mill to grind until the waste catalyst particle size D90=0.147mm ;

[0037] Table 1 Composition Data Table of Vanadium-containing Waste Catalyst

[0038] substance V 2 o 5

Mo Ni co Fe C S P al 2 o 3

oily hydrocarbons content(%) 16.30 2.02 6.82 0.15 1.38 15.49 9.61 0.30 19.58 12.53

[0039] (2) with the Na 2 CO 3 (200kg) add simultaneously in the roller mixer and carry out once rolling, and the rolling time is 15min; Then add the water glass of powdery spent catalyst gross mass 3%, the sodium bentonite of 2% and the water of 7%, secondary Roll and mix for 15 minutes to obtain the mixed material;

[0040] (3) Add the mixed material obtained in step (2) into the disc granulator, and sp...

Embodiment 2

[0045] (1) Get the same deoiled vanadium-containing waste catalyst 500kg as in Example 1, put it into high-energy ball milling, until the waste catalyst particle size D90=0.147mm;

[0046] (2) with step (1) gained powdery waste catalyst and 30% Na 2 CO 3 (150kg) is added in the roll mixer simultaneously and carries out once rolling, and the rolling time is 15min; Then add the water glass of powdery spent catalyst gross mass 3%, the sodium bentonite of 2% and the water of 7%, secondary Roll and mix for 15 minutes to obtain the mixed material;

[0047] (3) Add the mixed material obtained in step (2) into the disc granulator, and spray water into it at the same time to prepare the mixed material granules, whose particle size is controlled as D90=3mm;

[0048] (4) Flatten the mixed material granules obtained in step (3), blow in hot air at 150° C. for 1 hour to dry the mixed material granules, and naturally freeze the obtained dried granules in the air for 4 hours to obtain cold...

Embodiment 3

[0052] (1) Get the same deoiled vanadium-containing waste catalyst 500kg as in Example 1, put it into high-energy ball milling, until the waste catalyst particle size D90=0.147mm;

[0053] (2) with step (1) gained powdery waste catalyst and 40% Na 2 CO 3 (200kg) add simultaneously in the roller mixer and carry out once rolling, and the rolling time is 15min; Then add the water glass of powdery spent catalyst gross mass 5%, the sodium bentonite of 4% and the water of 7%, secondary Roll and mix for 15 minutes to obtain the mixed material;

[0054] (3) Add the mixed material obtained in step (2) into the disc granulator, and spray water into it at the same time to prepare the mixed material granules, whose particle size is controlled as D90=3mm;

[0055] (4) Flatten the mixed material granules obtained in step (3), and blow hot air at 150°C for 1 hour to dry the mixed material granules. The resulting dried granules are naturally cooled in the air for 4 hours to obtain cold-set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com