Preparation method of adhesive-feeling-free heat-shrinkable heat-sticking universal high-transmittance protective film

A protective film, heat shrinking technology, applied in the direction of adhesive, film/sheet adhesive, adhesive type, etc., can solve the problem of not enough environmental protection, anti-scratch, waterproof and other properties, liquid crystal panel easy to yellow, Dirt and other problems, to achieve high transparency and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

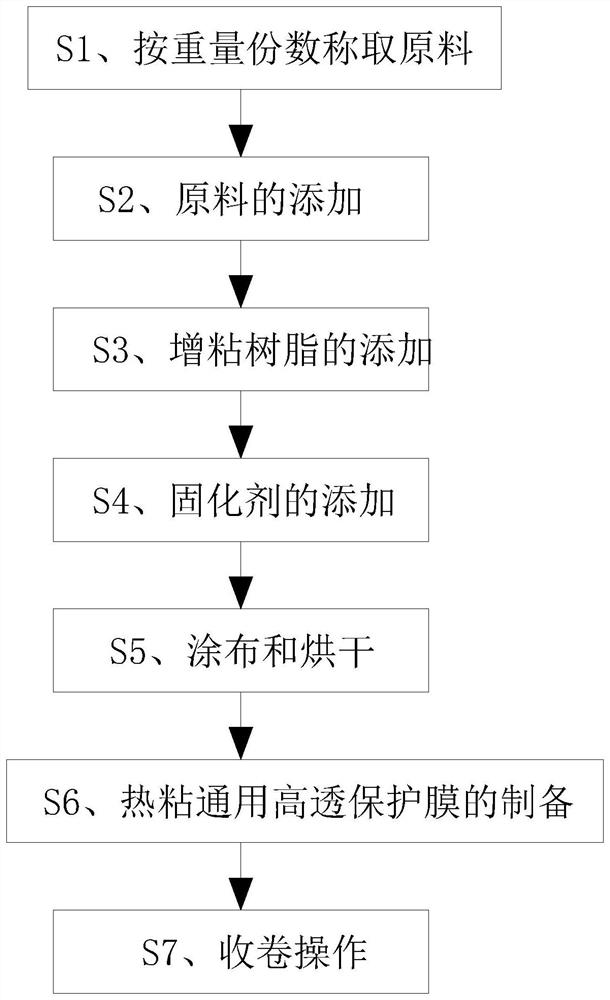

[0026] Example 1: Please refer to figure 1 , the invention discloses a method for preparing a heat-adhesive universal high-transparency protective film that can be heat-shrinkable without glue feeling, comprising the following steps:

[0027] S1. Weigh raw materials by weight: 15 parts of tackifying resin, 25 parts of acrylate pressure-sensitive adhesive, 3 parts of auxiliary agent, 12 parts of inorganic filler, 1 part of coupling agent, 20 parts of curing agent and 10 parts of solvent.

[0028] S2, addition of raw materials: put the auxiliary agent and coupling agent weighed in step S1 into the reaction kettle, add the solvent in step S1 to the reaction kettle, and add the diluted auxiliary agent and coupling agent under the condition of stirring Inorganic filler is added to the mixed solution of coupling agent, the coupling agent is aluminate coupling agent, the auxiliary agent is silicon dioxide, the solvent is ethyl acetate, and the inorganic inorganic filler is aluminum o...

Embodiment 2

[0034] Example 2: Please refer to figure 1 , the invention discloses a method for preparing a heat-adhesive universal high-transparency protective film that can be heat-shrinkable without glue feeling, comprising the following steps:

[0035] S1. Weigh raw materials by weight: 18 parts of tackifying resin, 30 parts of acrylate pressure-sensitive adhesive, 4 parts of auxiliary agent, 11 parts of inorganic filler, 3 parts of coupling agent, 22 parts of curing agent and 13 parts of solvent.

[0036] S2, addition of raw materials: put the auxiliary agent and coupling agent weighed in step S1 into the reaction kettle, add the solvent in step S1 to the reaction kettle, and add the diluted auxiliary agent and coupling agent under the condition of stirring Inorganic fillers are added to the mixed solution of the coupling agent, the coupling agent is an aluminate coupling agent, the auxiliary agent is silicon dioxide, the solvent is acetone, and the inorganic inorganic filler is alumin...

Embodiment 3

[0042] Example 3: Please refer to figure 1 , the invention discloses a method for preparing a heat-adhesive universal high-transparency protective film that can be heat-shrinkable without glue feeling, comprising the following steps:

[0043] S1. Weigh raw materials by weight: 20 parts of tackifying resin, 35 parts of acrylate pressure-sensitive adhesive, 5 parts of auxiliary agent, 15 parts of inorganic filler, 3 parts of coupling agent, 25 parts of curing agent and 15 parts of solvent.

[0044] S2, addition of raw materials: put the auxiliary agent and coupling agent weighed in step S1 into the reaction kettle, add the solvent in step S1 to the reaction kettle, and add the diluted auxiliary agent and coupling agent under the condition of stirring Inorganic filler is added to the mixed solution of coupling agent, the coupling agent is titanate coupling agent, the auxiliary agent is organic resin microspheres, the solvent is propylene glycol methyl ether acetate, and the inorgan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com