Water-based polyamide-imide anti-corrosion non-stick coating and preparation method thereof

A polyamide-imide, non-stick coating technology, used in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of poor safety, high VOCs emission, and anti-corrosion performance to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

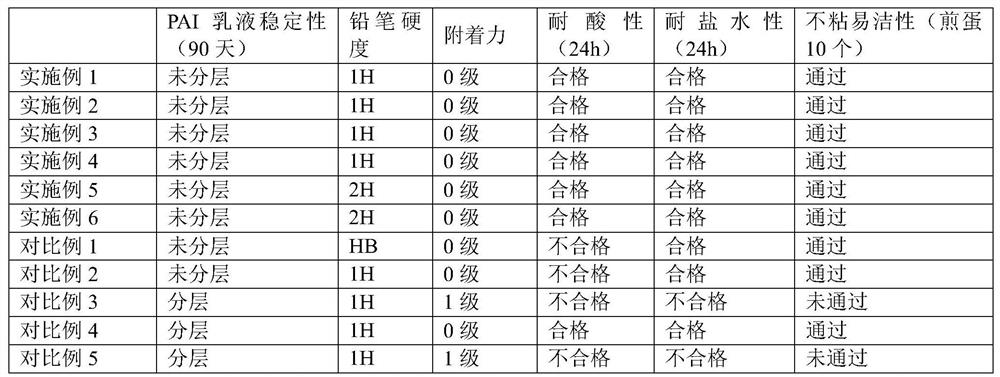

Examples

preparation example Construction

[0062] A preparation method of water-based polyamide-imide anti-corrosion non-stick coating, comprising the following steps:

[0063] 1) Preparation of PAI:

[0064] 1.1) Scheme 1: add trimellitic anhydride to the reaction flask and dissolve in N-methylpyrrolidone and xylene, under the protection of an inert gas, heat to 70-90°C, when the trimellitic anhydride is completely dissolved, add diphenylmethane-4, 4'-diisocyanate, heat preservation reaction for 1-3h, heat up to 120-140°C, continue heat preservation reaction for 3-5h, wash with absolute ethanol, suction filter and dry to obtain PAI; trimellitic anhydride and diphenylmethane-4,4 The molar ratio of '-diisocyanate is 1:1-1.05, the quality of N-methylpyrrolidone is 2-3 times of the sum of trimellitic anhydride and diphenylmethane-4,4'-diisocyanate, and the content of xylene is 5- 10 wt%.

[0065] 1.2) Option 2:

[0066] Preparation of isocyanate-terminated polyamide-imide: dissolve the acid anhydride in a solvent, heat...

Embodiment 1

[0075] 1) Preparation of PAI: Add trimellitic anhydride to the reaction flask and dissolve in NMP and xylene, under nitrogen protection, heat to 70°C, when trimellitic anhydride is completely dissolved, add diphenylmethane-4,4'-diisocyanate, Heat preservation reaction for 3 hours, heat up to 120°C, continue heat preservation reaction for 5 hours, wash with absolute ethanol, suction filter and dry to obtain PAI. The mol ratio of trimellitic anhydride and diphenylmethane-4,4'-diisocyanate is 1:1, the quality of NMP is 2 times of the sum of trimellitic anhydride and diphenylmethane-4,4'-diisocyanate, and the content of xylene is 5wt%.

[0076] 2) Preparation of PAI emulsion: Dissolve the PAI prepared in step 1) in 5wt% of NMP, add 1wt% of SDBS and TMN-10 with a mass ratio of 1:6, mix evenly with high-speed shear stirring, and the stirring rate is 6000rpm , and then dropwise add 70wt% deionized water until the viscosity of the system drops suddenly, less than 1Pa·s, add the unfin...

Embodiment 2

[0079] 1) Preparation of PAI: add trimellitic anhydride to the reaction flask and dissolve in NMP and xylene, under nitrogen protection, heat to 90°C, when the trimellitic anhydride is completely dissolved, add diphenylmethane-4,4'-diisocyanate, Heat preservation reaction for 1 hour, heat up to 140°C, continue heat preservation reaction for 3 hours, wash with absolute ethanol, suction filter and dry to obtain PAI. The mol ratio of trimellitic anhydride and diphenylmethane-4,4'-diisocyanate is 1: 1.05, the quality of NMP is 3 times of the sum of trimellitic anhydride and diphenylmethane-4,4'-diisocyanate, and the content of xylene is 10 wt%.

[0080] 2) Preparation of PAI emulsion: Dissolve the PAI prepared in step 1) in 10wt% NMP, add 2wt% of STBS and TMN-6 with a mass ratio of 1:2, mix evenly with high-speed shear stirring, and the stirring rate is 4000rpm , and then dropwise add 65wt% deionized water until the viscosity of the system suddenly drops to less than 1Pa·s, add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com