Defoaming device for biochemical treatment of sewage

A defoaming device and biochemical treatment technology, applied in water/sewage multi-stage treatment, degassed water/sewage treatment, water/sludge/sewage treatment, etc. The problem of large consumption, etc., can achieve the effect of reducing the operating failure rate, reducing moving parts, and high defoaming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

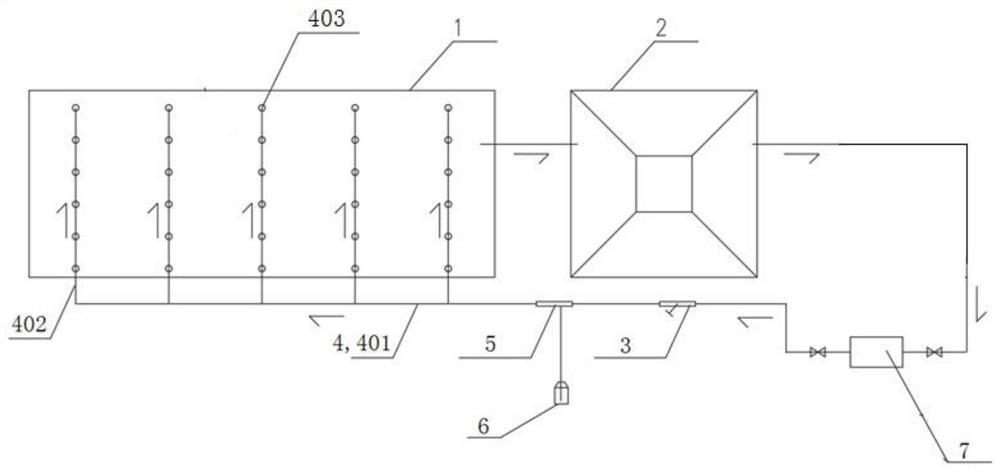

[0043] The defoaming device used for sewage biochemical treatment described in this embodiment, such as figure 1 As shown, it includes an aerobic tank 1, a sedimentation tank 2, a filter 3, a water injector 5 connected to a defoamer storage 6, and a spray pipeline 4. The aerobic tank 1 is connected to a sedimentation tank 2, and the sedimentation tank 2 is sequentially The spray pipeline 4 is connected with the circulation pump 7, the filter 3 and the water ejector 5, and the circulation pump 7 transfers the supernatant of the sedimentation tank 2 into the water ejector 5, and the water ejector 5 sucks the defoamer and mixes with the supernatant After mixing, enter the spray pipeline 4.

[0044] The spray pipeline 4 includes a main pipe 401 and five branch pipes 402 connected in parallel with it. The water inlet end of the main pipe 401 is connected to the water outlet end of the water ejector 5. The branch pipes 402 are perpendicular to the water flow direction in the aerobic...

Embodiment 2

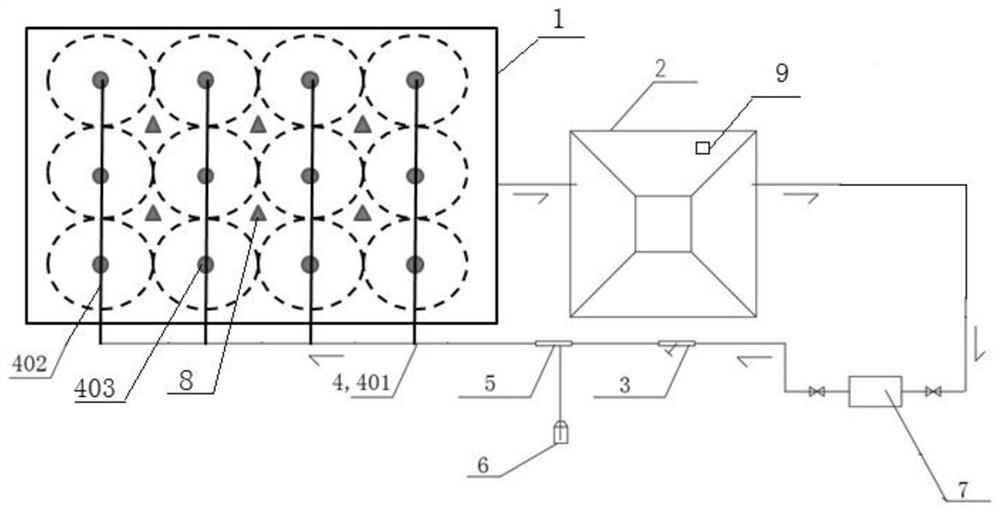

[0046] The defoaming device used for sewage biochemical treatment described in this embodiment, such as figure 2 and 3 As shown, it includes an aerobic tank 1, a sedimentation tank 2, a filter 3, a spray pipeline 4, and a water injector 5 connected to a defoamer storage 6. The aerobic tank 1 is connected to the sedimentation tank 2 through a pipeline, and biological treatment The final sewage enters the sedimentation tank 2 for mud-water separation, and the upper part of the sedimentation tank is the supernatant. The upper part of the sedimentation tank 2 is connected to the outlet pipe, and the sedimentation tank 2 is connected to the spray pipeline 4 through the circulation pump 7, the filter 3 and the water injector 5 in turn, and the circulation pump 7 inputs the supernatant of the sedimentation tank 2 into the water injector 5, The water ejector 5 inhales the defoamer and mixes it with the supernatant and then enters the spray pipeline 4; the supernatant of the sediment...

Embodiment 3

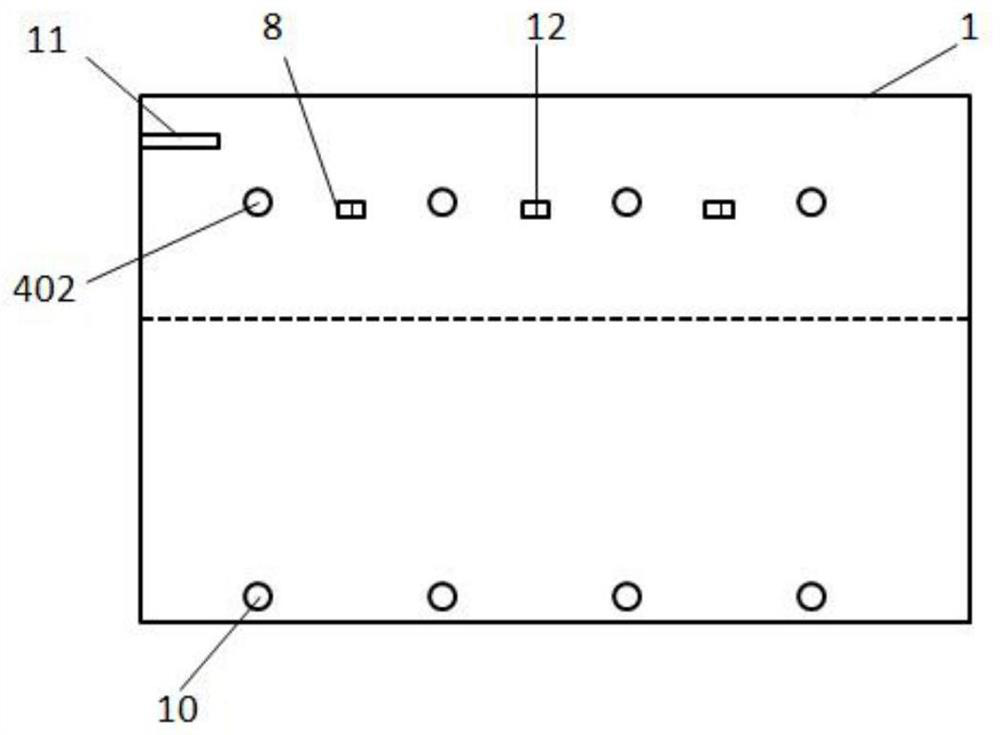

[0060] The defoaming device used for sewage biochemical treatment described in this embodiment, such as image 3 and 4 As shown, a pressure gauge 12 is added to the radio frequency admittance level switch, and the pressure gauge is connected to the control system as a supplement to the radio frequency admittance level switch.

[0061] Described defoaming device also comprises clear water tank 13 and the 3rd liquid level gauge 14, and clear water tank 13 is located at the downstream side of sedimentation tank 2, and is connected with sedimentation tank 2 by pipeline, and the outlet pipeline of clear water tank 13 is connected circulation pump 7, and the second Three liquid level gauges 14 are arranged in the clear water tank 13 to monitor the liquid level. The third liquid level gauge 14 is an ultrasonic liquid level gauge, and the third liquid level gauge 14 is connected to the control system. The supernatant in the sedimentation tank 2 is input into the clear water tank 13 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com