Barium silicate microspheres as well as preparation method and application thereof

A technology of barium silicate and microspheres, applied in silicates, alkaline earth metal silicates, chemical instruments and methods, etc., can solve problems such as high energy consumption, environmental pollution, and complicated synthesis steps, and achieve low energy consumption, Strong controllability and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

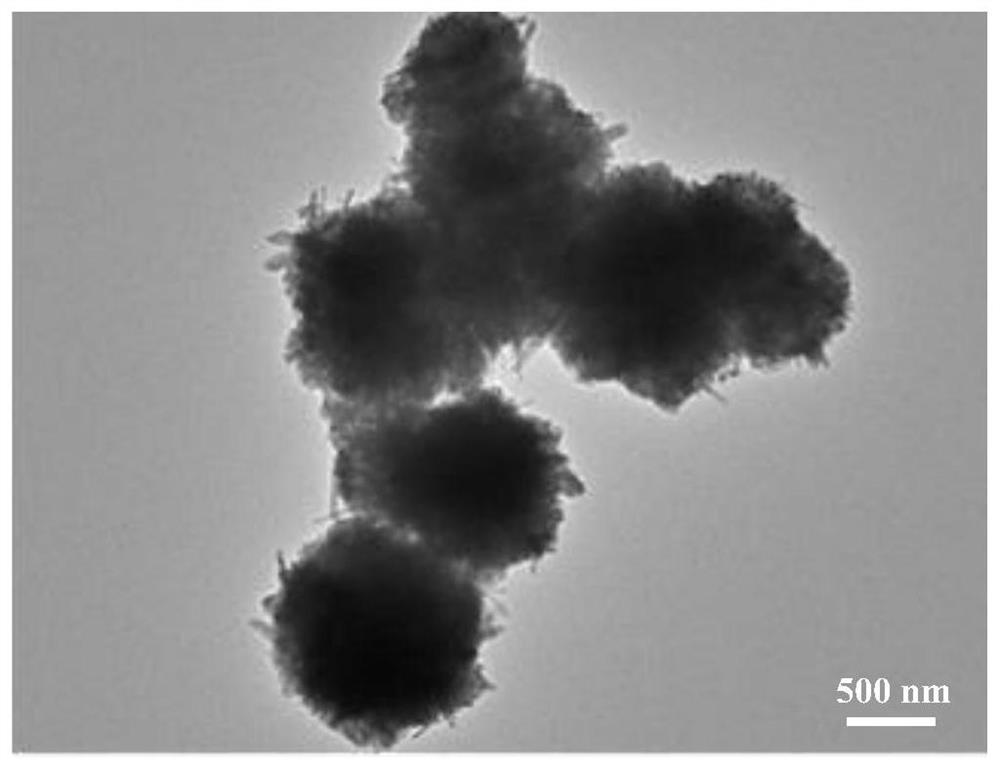

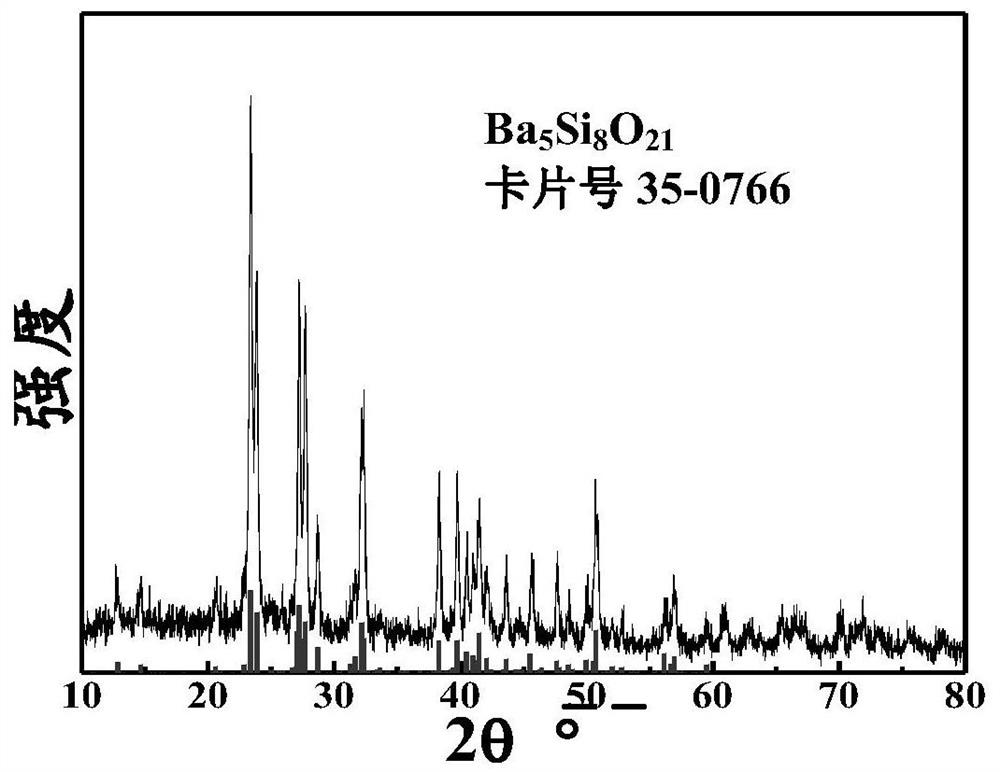

[0039] A barium silicate (Ba 5 Si 8 o 21 ) microspheres, the preparation method of which is as follows:

[0040] (1) 5mmol BaCl 2 and 10 mmol Na 2 SiO 3 The solid was added to 30mL and 20mL deionized water respectively, and after magnetic stirring (300r / min) for 20min, colorless and clear solutions A and B were obtained;

[0041] (2) Under magnetic stirring at 300r / min, add solution B dropwise to solution A at a rate of 10 drops / min, and continue stirring at 20°C for 10 minutes to obtain white suspension C;

[0042] (3) The suspension C was transferred to a polytetrafluoroethylene liner for sealing, and under the condition that the rotation frequency of the homogeneous reactor (JXF-0-200) was 10Hz, the temperature was raised to 120°C at a heating rate of 5°C / min. After constant temperature reaction for 6.0 h, it was naturally cooled to room temperature to obtain a hydrothermal product;

[0043] (4) The hydrothermal product was washed 3 times with deionized water and 1 t...

Embodiment 2

[0047] A barium silicate (Ba 5 Si 8 o 21 ) microspheres, the preparation method of which is as follows:

[0048] (1) 2.5mmol BaCl 2 and 5 mmol Na 2 SiO 3 The solid was added to 30mL and 20mL deionized water respectively, and magnetically stirred (250r / min) for 25min to obtain colorless and clear solutions A and B;

[0049] (2) Under magnetic stirring at 250r / min, add solution B dropwise to solution A at a rate of 20 drops / min, and continue stirring at 18°C for 10 minutes to obtain white suspension C;

[0050] (3) Transfer the suspension C to a polytetrafluoroethylene liner and seal it. Under the condition that the rotation frequency of the homogeneous reactor (JXF-0-200) is 10Hz, the temperature is raised to 200°C at a heating rate of 8°C / min. After constant temperature reaction for 6.0 h, it was naturally cooled to room temperature to obtain a hydrothermal product;

[0051] (4) The hydrothermal product was washed twice with deionized water, washed twice with absolute...

Embodiment 3

[0055] A barium silicate (Ba 5 Si 8 o 21 ) microspheres, the preparation method of which is as follows:

[0056] (1) 2.5mmol BaCl 2 and 5 mmol Na 2 SiO 3 The solid was added to 30mL and 20mL deionized water respectively, and magnetically stirred (500r / min) for 5min to obtain colorless and clear solutions A and B;

[0057] (2) Under 500r / min magnetic stirring, add solution B dropwise to solution A at a rate of 10 drops / min, and continue stirring at 35°C for 10 minutes to obtain white suspension C;

[0058] (3) The suspension C was transferred to a polytetrafluoroethylene liner and sealed, and the temperature was raised to 150°C at a heating rate of 5°C / min in a static state, and after a constant temperature reaction for 12.0 hours, it was naturally cooled to room temperature to obtain a hydrothermal product;

[0059] (4) The hydrothermal product was washed 3 times with deionized water and 2 times with absolute ethanol, filtered with a Buchner funnel, and dried at 100°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com