Wall surface grinding machine for decoration

A technology for grinding machines and grinding discs, which is applied in the direction of grinding racks, machine tools suitable for grinding workpiece planes, and parts of grinding machine tools. It can solve problems such as equipment damage, hidden safety hazards for decoration workers, and hands-off problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

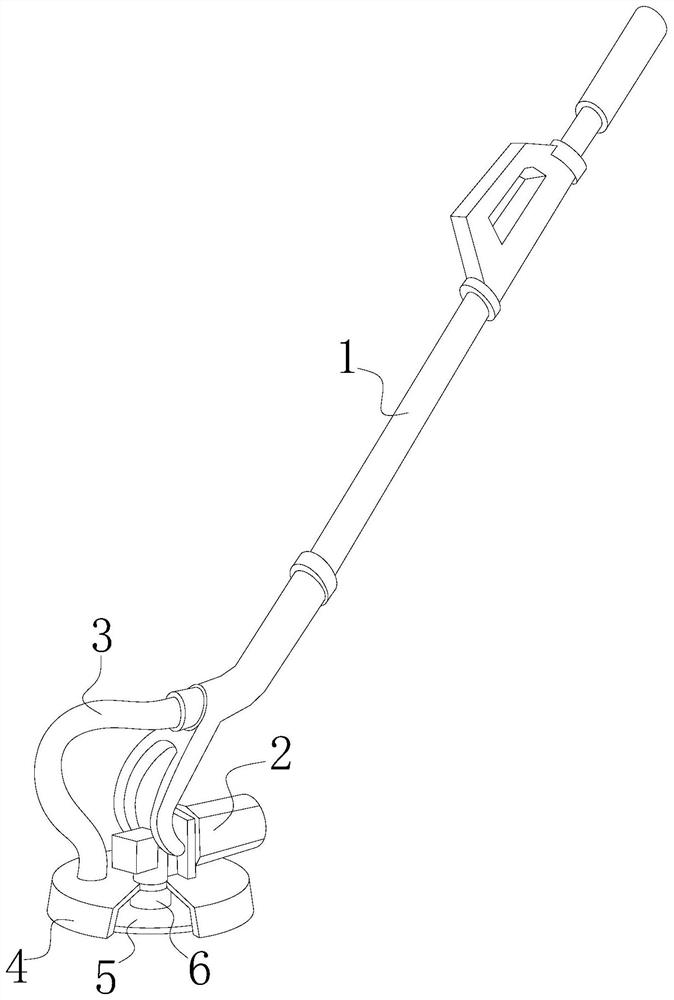

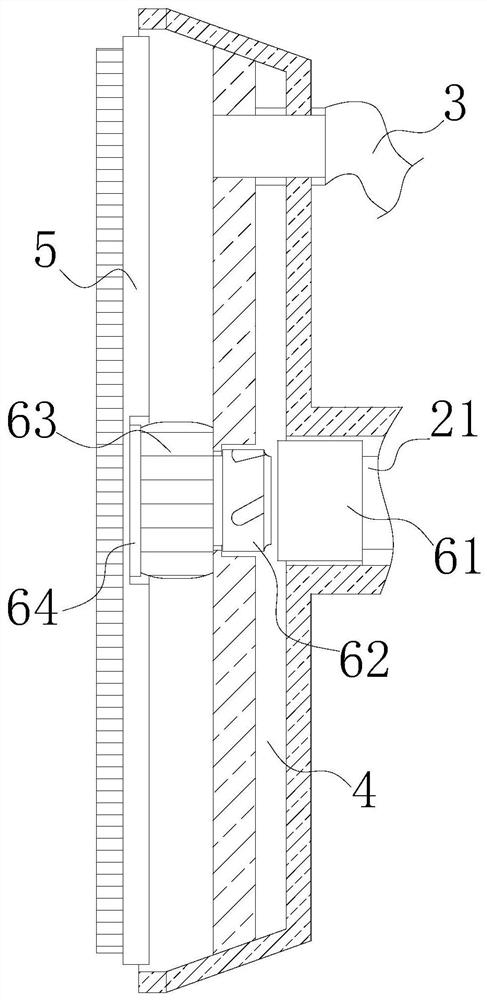

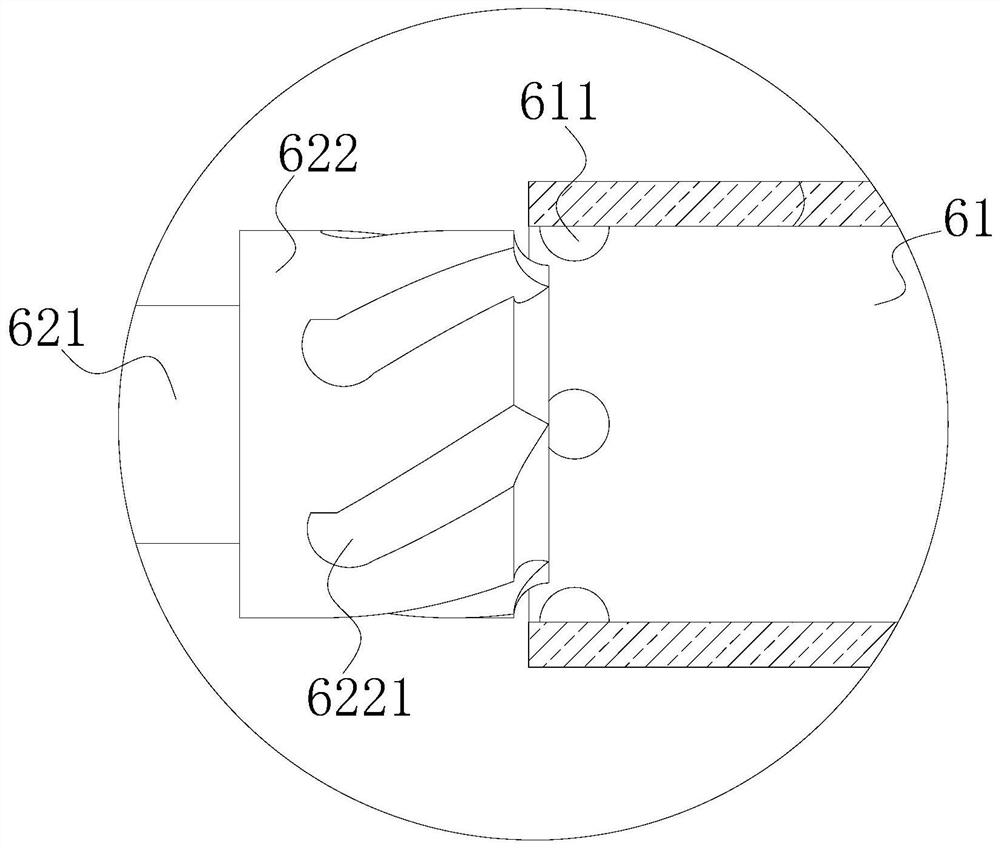

[0029] Such as figure 1 , figure 2 As shown, the present invention provides a wall grinder for decoration, its structure includes: a handle 1, a carbon brush motor 2, a conduit 3, a head shell 4, a grinding disc 5, a connecting device 6, and the head shell 4 snaps Closed on the front end of the handle 1, the conduit 3 is arranged in the handle 1 and communicates with the head case 4, the carbon brush motor 2 is arranged on the back of the head case 4, and the grinding disc 5 is arranged on the front of the head case 4 Inside the front end, the grinding disc 5 is connected to the carbon brush motor 2 through the connection device 6 provided inside the head shell 4. The connection device 6 is composed of a main shaft 61, a transmission shaft 62, a compression sleeve 63, and a bearing 64. The main shaft 61 is connected to the carbon brush motor 2, the left end of the transmission shaft 62 is vertically fixed to the grinding disc 5, the right end of the transmission shaft 62 is ...

Embodiment 2

[0035] Such as figure 1 , figure 2As shown, the present invention provides a wall grinder for decoration, its structure includes: a handle 1, a carbon brush motor 2, a conduit 3, a head shell 4, a grinding disc 5, a connecting device 6, and the head shell 4 snaps Closed on the front end of the handle 1, the conduit 3 is arranged in the handle 1 and communicates with the head case 4, the carbon brush motor 2 is arranged on the back of the head case 4, and the grinding disc 5 is arranged on the front of the head case 4 Inside the front end, the grinding disc 5 is connected to the carbon brush motor 2 through the connection device 6 provided inside the head shell 4. The connection device 6 is composed of a main shaft 61, a transmission shaft 62, a compression sleeve 63, and a bearing 64. The main shaft 61 is connected to the carbon brush motor 2, the left end of the transmission shaft 62 is vertically fixed to the grinding disc 5, the right end of the transmission shaft 62 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com