Method for expanding, drawing and forming metal pipe

A technology for metal pipes and pipes, which is applied in the direction of wire drawing dies, etc., can solve the problems of low dimensional accuracy, uneven deformation of inner and outer diameters, and uneven wall thickness reduction in the production of pipes, so as to improve the forming quality and forming efficiency and reduce the uneven expansion. Uniformity, the effect of improving the forming quality and forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

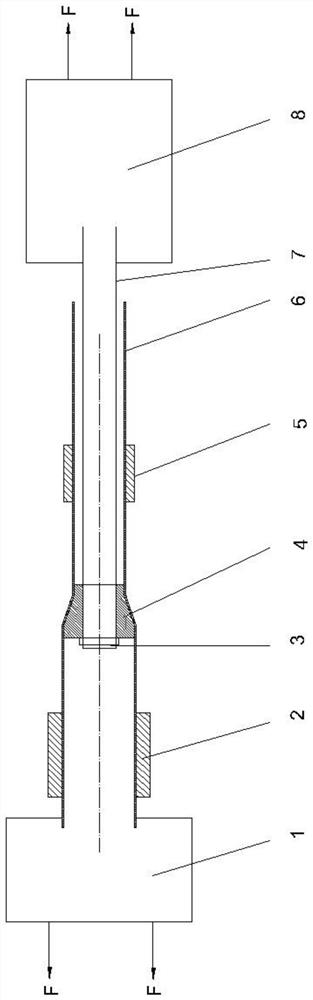

Image

Examples

Embodiment 1

[0032] The first step is to polish the surface of the stainless steel tube. After the grinding is completed, use the prepared mixed acid solution for pickling treatment. After pickling, wash with water to remove the residual mixed acid on the stainless steel tube. Dry after washing;

[0033] In the second step, one end of the stainless steel tube is heat-treated, and the diameter is simply expanded in a hot state, so that the diameter of the stainless steel tube is larger than the maximum diameter of the expanding die, so that the expanding die can smoothly enter the interior of the stainless steel tube;

[0034] The third step is to inject stretching oil into the stainless steel pipe;

[0035] The fourth step is to place the stainless steel pipe on the machine tool through the guide device and the sizing device;

[0036] The fifth step is to pass the core rod through the stainless steel tube. The front end of the core rod is equipped with a detachable expanding die, and the r...

Embodiment 2

[0046] The first step is to polish the surface of the GH4169 tube. After the grinding is completed, use the prepared mixed acid solution for pickling treatment. After pickling, wash with water to remove the residual mixed acid on the GH4169 tube. After washing, dry it;

[0047] In the second step, one end of the GH4169 tube is heat treated, and the diameter is simply expanded in a hot state, so that the diameter of the GH4169 tube is larger than the maximum diameter of the expanding die, so that the expanding die can smoothly enter the inside of the GH4169 tube;

[0048] The third step is to introduce stretching oil into the GH4169 pipe;

[0049] The fourth step is to place the GH4169 pipe on the machine tool through the guide device and the sizing device;

[0050] The fifth step is to pass the core rod through the GH4169 tube. The front end of the core rod is equipped with a detachable expansion die, and the rear end of the core rod is connected to the drawing machine;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com