Novel UHPC (Ultra High Performance Concrete) partition plate

An ultra-high-strength concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as partition leaks, cover plate displacement, and center plate detachment, and improve the degree of cross-linking of the system , Fast curing speed and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

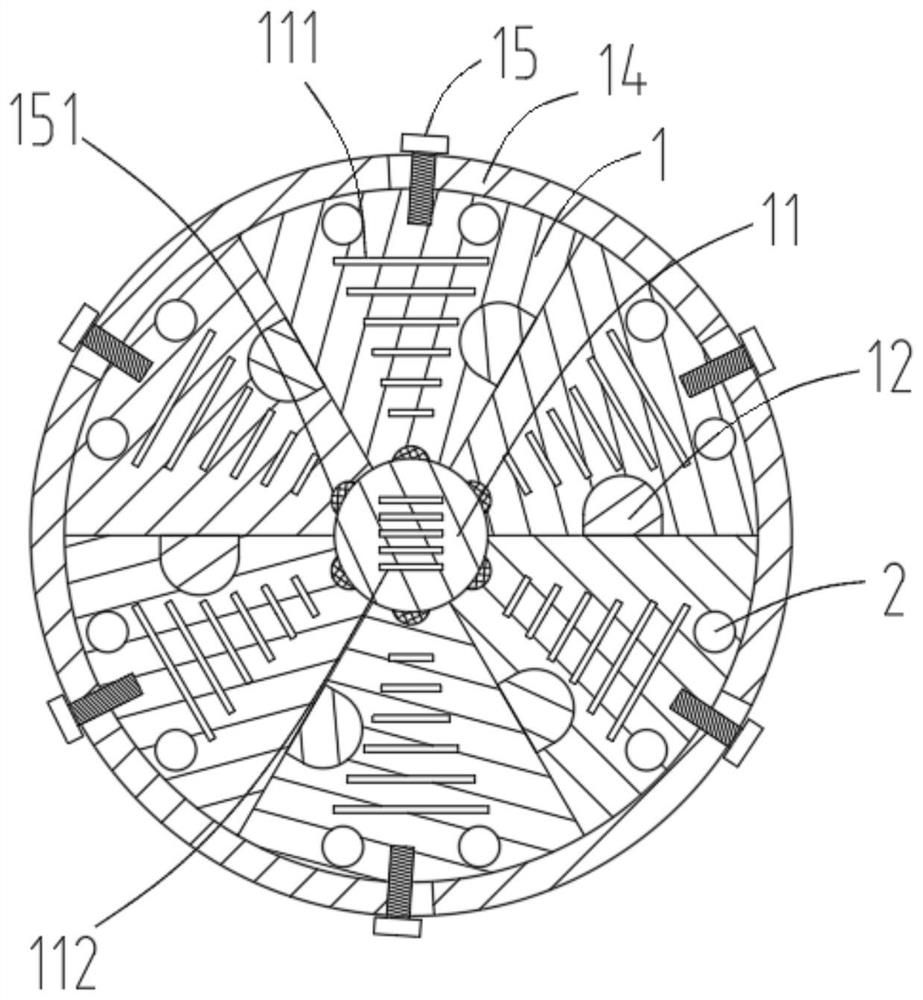

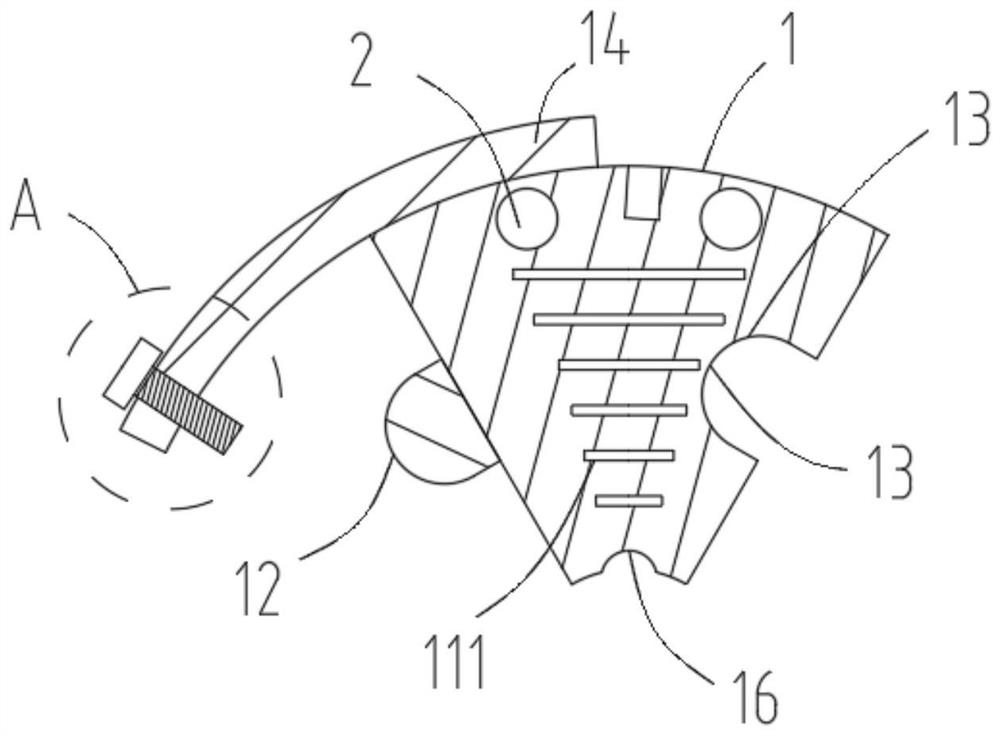

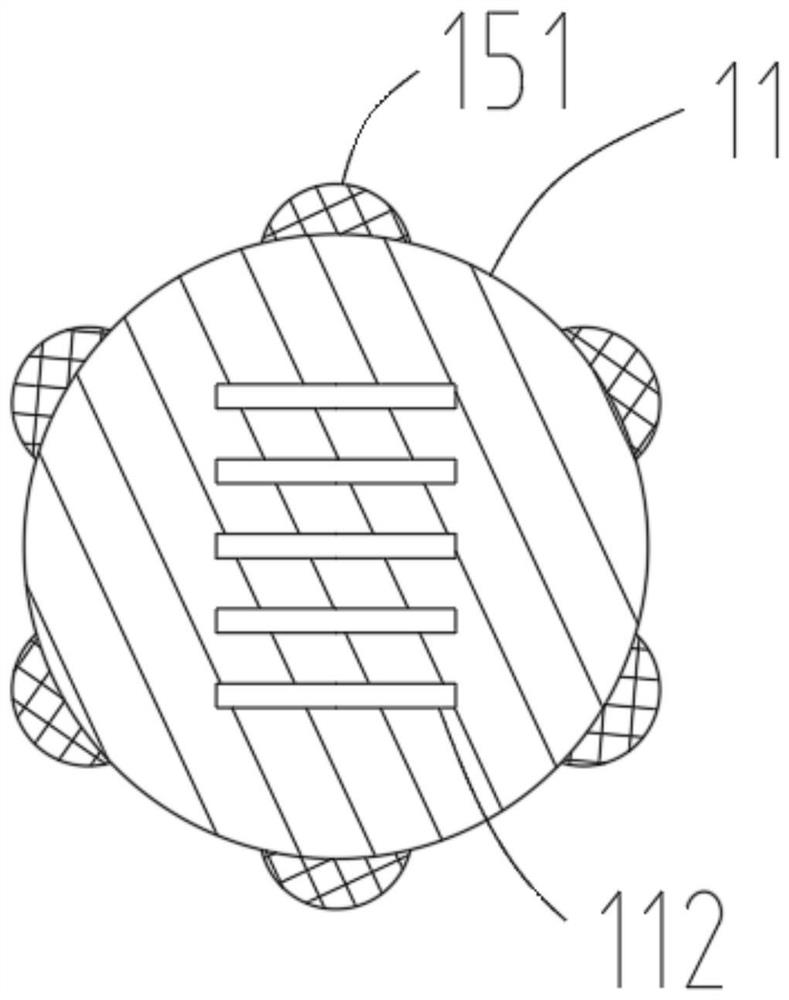

[0031] Such as Figure 1-4 As shown, the novel ultra-high-strength concrete UHPC compartment plate provided by the present invention includes six grate plates 1 and a central plate 11, and the six grate plates 1 are spliced into a 360-degree circular plate around the central plate 11, and each grate plate There are two second through-holes 2 on the plate 1, and the grate plate 1 is fixed in the working position by driving nails into the second through-holes 2, and each grate plate 1 is provided with a number of first filter grooves 111, the central plate 11 is provided with a number of second filter tanks 112, and the grinding body that has been roughly ground in the first warehouse of the ball mill enters the second warehouse through the first filter tank 111 and the second filter tank 112, and each grate plate One end of 1 is fixedly connected with a clamping plate 12, the surface of one side of the clamping plate 12 is curved, and the other side of each grate plate 1 is p...

Embodiment 2-1

[0050] The preparation method of grate plate or center plate, the steps are as follows:

[0051] (1) Add 100 parts of Portland cement, 50 parts of fly ash, 3 parts of expansion agent, 10 parts of silica fume, 60 parts of quartz sand, 30 parts of steel fiber, and 60 parts of aggregate into the mixer at 200r / min After fully mixing for 100 seconds, Mixture 1 was obtained;

[0052] (2) Add 3 parts of water reducer to 30 parts of water, and mix well to obtain Mixture 2;

[0053] (3) Add 1 part of amino-containing polybenzimidazole into 5 parts of dimethyl sulfoxide, and after fully dissolving, mixture 3 is obtained;

[0054] (4) Add 1 part of sulfonated polyphenylene and 1 part of KH-560 into 10 parts of ethanol, and mix thoroughly to obtain Mixture 4;

[0055] (5) After fully mixing the above-mentioned mixtures 1, 2, 3 and 4 at 200r / min at 50°C for 150 seconds, the ultra-high performance concrete is obtained;

[0056] (6) After the ultra-high-performance concrete is molded, for...

Embodiment 2-2

[0058] The preparation method of grate plate or center plate, the steps are as follows:

[0059] (1) Add 100 parts of Portland cement, 54 parts of fly ash, 7 parts of expansion agent, 13 parts of silica fume, 77 parts of quartz sand, 35 parts of steel fiber, and 78 parts of aggregate into the mixer at 200r / min After fully mixing for 100 seconds, Mixture 1 was obtained;

[0060] (2) Add 6 parts of water reducer to 65 parts of water, and mix well to obtain Mixture 2;

[0061] (3) Add 3 parts of amino-containing polybenzimidazole into 8 parts of dimethyl sulfoxide, and after fully dissolving, mixture 3 is obtained;

[0062] (4) Add 3 parts of sulfonated polyphenylene and 4 parts of KH-560 into 12 parts of ethanol, and mix thoroughly to obtain Mixture 4;

[0063] (5) After fully mixing the above-mentioned mixtures 1, 2, 3 and 4 at 200r / min at 50°C for 150 seconds, the ultra-high performance concrete is obtained;

[0064] (6) After the ultra-high-performance concrete is molded, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com