Air bag sealing type side spraying pelleting structure

A technology of air bag sealing and pill making, which is applied in the field of fluidized bed, and can solve the problems of high failure rate, complex structure, high processing and assembly precision requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

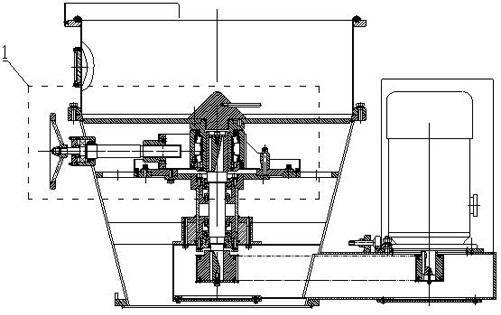

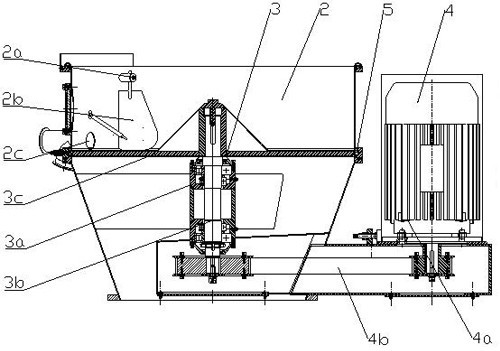

[0042] An airbag-sealed side shot peening structure, comprising:

[0043] A material cylinder 2, a spray gun 2a is installed inside the material cylinder 2;

[0044] The turntable assembly 3, the turntable assembly 3 is rotatably arranged inside the material cylinder 2, the turntable assembly 3 is in the shape of a disc, and there is a gap between the edge of the turntable assembly 3 and the inner wall of the material cylinder 2;

[0045] The rotary driver 4 is fixedly installed on the material cylinder 2, and the output end of the rotary driver 4 is connected to the turntable assembly 3 through transmission;

[0046] Also includes,

[0047] The hollow sealing ring 5 is coaxially installed inside the material cylinder 2, and the hollow sealing ring 5 is arranged between the material cylinder 2 and the turntable assembly 3;

[0048] Filling device (not shown in the figure), the filling device is fixedly installed on the material cylinder 2, and the filling device is used to f...

Embodiment 2

[0093] The difference from Example 1 is:

[0094] One side of the material cylinder 2 is provided with a discharge pipe 2c whose bottom end is flush with the top surface of the turntable assembly 3, and a valve (not shown in the figure) is installed on the discharge pipe 2c.

[0095] Specifically, except for the discharge state, the valve always closes the discharge pipe 2c, so that the material will not be removed through the discharge pipe 2c. When discharging is required, the valve is opened, so that the material can be discharged through the discharge pipe 2c, and the valve It can be a butterfly valve or a cylinder driven piston.

[0096] Working principle of embodiment two:

[0097] Step 1: start the air pump, the air pump fills the hollow sealing ring 5 with gas, and the hollow sealing ring 5 expands to block the gap between the material cylinder 2 and the turntable assembly 3;

[0098] Step 2, the spray gun 2a sprays the material into the material tank 2 until the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com