Method for measuring contents of aldehyde ketone in polyether modified organosilicon

A polyether modification, silicone technology, applied in measuring devices, instruments, scientific instruments, etc., to achieve the effects of good repeatability, simple pretreatment, high sensitivity and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

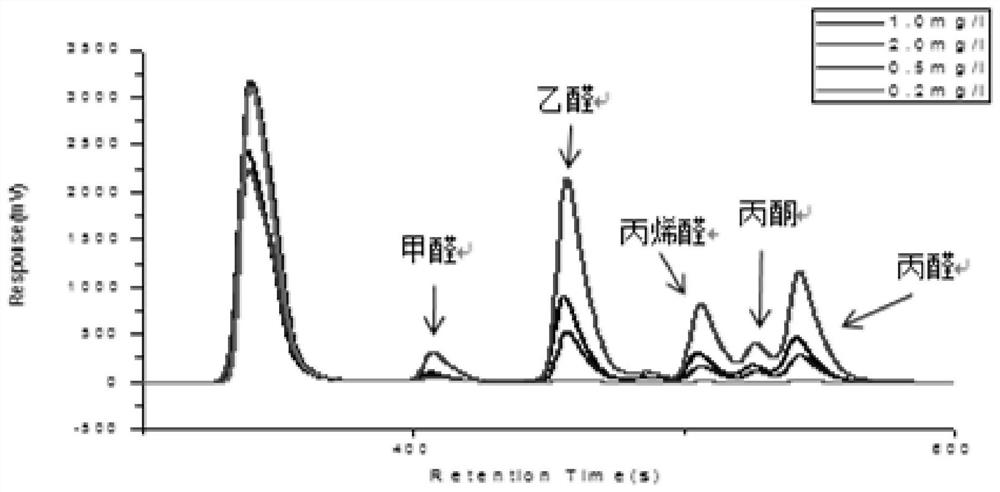

[0068] The instrument used in this experiment is a 1260 high performance liquid chromatograph from Agilent Company of the United States, equipped with a UV detector, and the wavelength of the detector is set to 360nm. The analytical column is Agilent C18 column, the model is 5um*4.6mm*250mm.

[0069] The embodiment of the present invention provides a method for measuring the content of aldehydes and ketones in polyether-modified silicone, including:

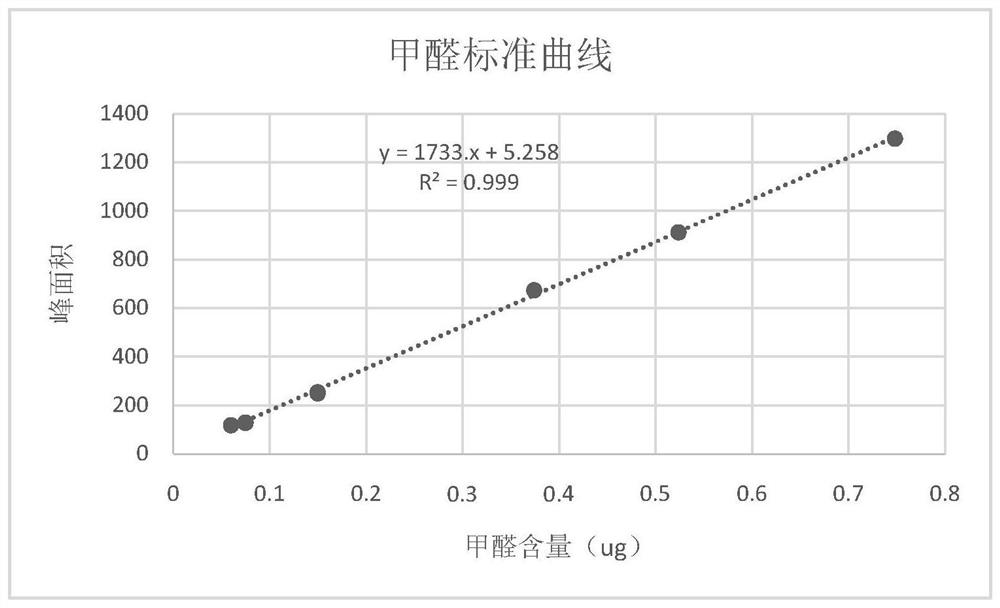

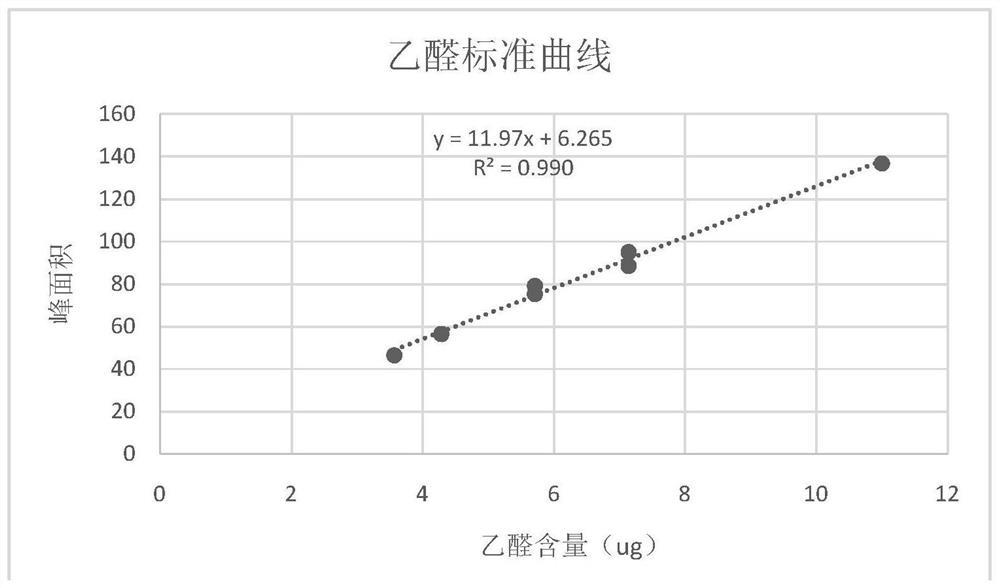

[0070] Select formaldehyde, acetaldehyde, acetone, acrolein, and propionaldehyde as the standard substances to be tested, and after accurate weighing, use chromatographic grade acetonitrile to prepare the concentrations of 0.05μg / ml, 0.1μg / ml, 0.5μg / ml, 1.0 Standard solutions of μg / ml, 1.5μg / ml, 3.0μg / ml, 5.0μg / ml, 10.0μg / ml; prepare 1% mass fraction of 2,4-dinitrophenylhydrazine solution with chromatographic grade acetonitrile, and use Chromatography-grade acetonitrile was used to prepare a 1% phosphoric acid solution.

[0071...

Embodiment 2- Embodiment 6

[0085]Detect with reference to the detection method of embodiment 1, the difference is that the polyether modified silicone sample that adopts is different, and embodiment 2 is marked as sample 2, and its molecular weight is about 1300, and embodiment 3 is marked as sample 3, and its molecular weight is about 2000, embodiment 4 is recorded as sample 4, and its molecular weight is about 3200, and embodiment 5 is recorded as sample 5, and its molecular weight is about 5000, and embodiment 6 is recorded as sample 6, and its molecular weight is about 5700, and the test results are as follows:

[0086]

[0087]

[0088] It should be noted that the samples provided in the examples of the present invention are self-made samples by the inventors, for example, sample 1 is a sample synthesized by referring to the synthesis method of document CN109942823A.

[0089] verify:

[0090] 1. Repetitive experiment

[0091] Select the polyether-modified silicone sample of Example 5 above, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com