Packer, string and method for rapid leak detection in whole wellbore

A packer and leaking pipe technology, applied in the field of oil drilling, can solve problems such as unreasonable pipe string structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

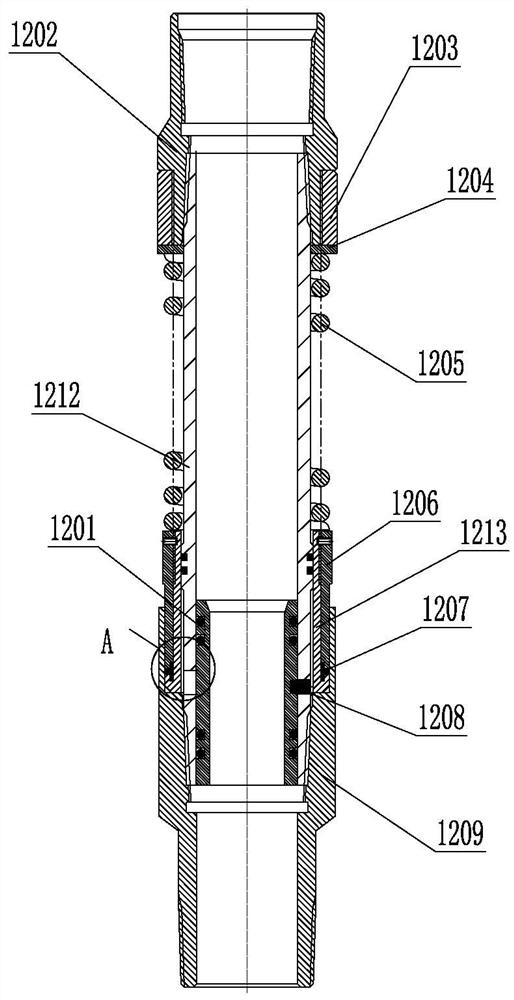

[0042] like Figure 5 and Image 6 The shown packer 11 for rapid leak detection in the whole wellbore, the packer 9 includes a central pipe 904, the upper and lower ends of the central pipe 904 are respectively connected with an upper joint 903 and a lower joint 901, and the central pipe 1 A rubber barrel 905 and a rubber barrel lower seat 907 are set on the 904. The rubber barrel lower seat 907 can slide up and down along the outer wall of the lower joint. The central tube 904 is connected with a sliding sleeve 908. The sliding sleeve 908 and the central tube 904 are connected. A shearing pin 909 is set between the two parts, and the lower seat 907 of the rubber barrel is in contact with the downward end of the lower seat 907 of the rubber barrel; the inner wall of the lower part of the lower seat 907 of the rubber barrel is threadedly connected with a limit ring 911, and the limit ring 911 can be along the lower joint one. 901 slides up and down, a limit step 913 is set at ...

Embodiment 2

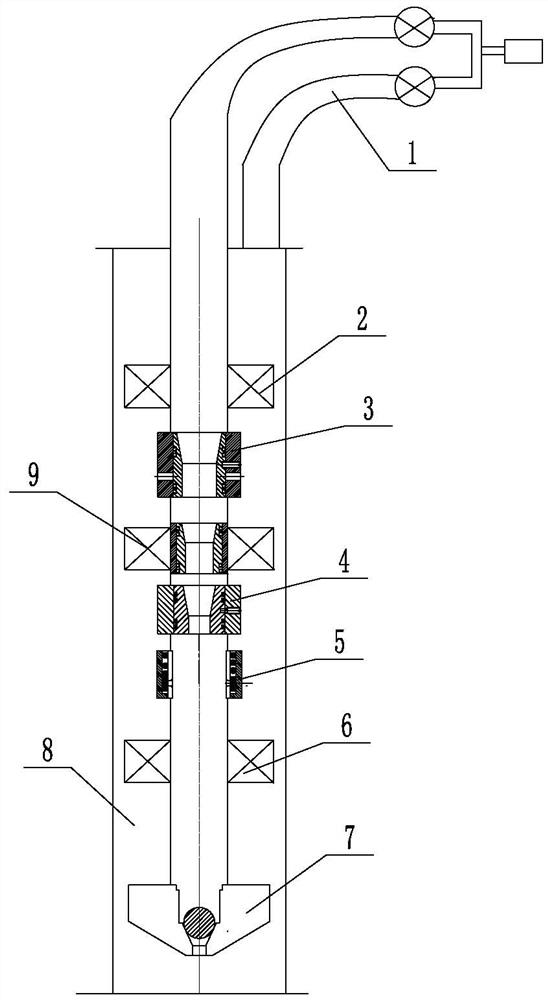

[0044] like figure 1 The upper bound leak-finding string using the packer 9 for upper bound leak detection shown includes the upper bound string body 8, and the upper bound string body 8 is sequentially connected with the upper bound packer 2, 2 and 2 from top to bottom. Pressure relief valve 1 3, packer 9, pressure test valve 1 4, upper limit restrictor 5, upper bound packer 1 6 and ball seat 1 7, the outer diameter of ball seat 1 7 is less than or equal to the diameter of the well gauge , play the role of well opening and protection, and righting the packer rubber cylinder 905; upper bound packer 1 6, upper bound packer 2 2, packer 9, upper bound choke 5, pressure test valve 1 4. Ball seat one 7 and pressure relief valve one 3 are coaxially arranged.

Embodiment 3

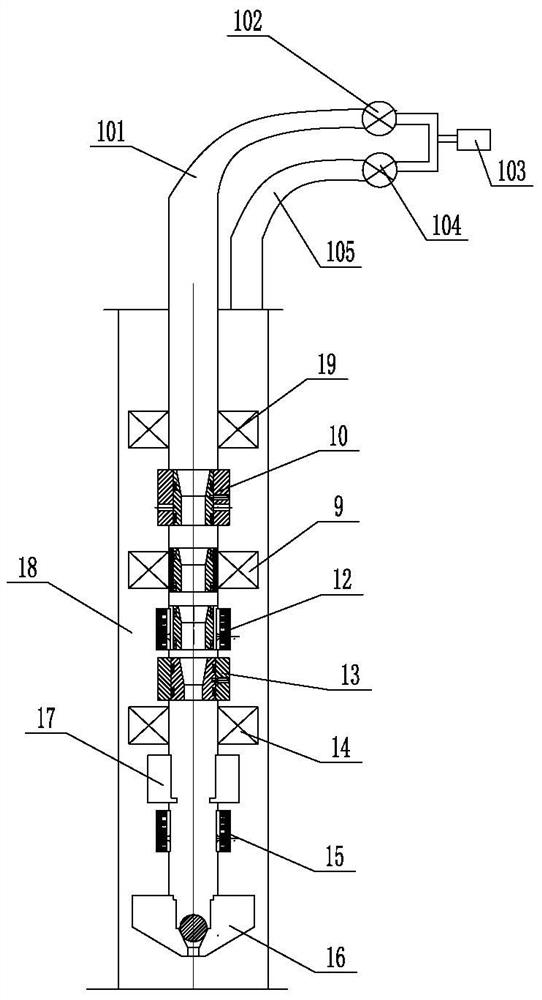

[0046] The method of using the upper bound leak-finding string to detect leaks in the upper bound. The upper end of the upper bound tubing string body 8 is connected with a leak-seeking string 1, and the leak-seeking string 1 includes a hose-101 connected to the body of the tubing string. and the second hose 105, the first hose 101 is connected with the oil pipe, the second hose 105 is connected with the oil casing annulus outside the oil pipe, and the first hose 101 and the second hose 105 outside the wellhead are respectively connected with a valve one 102 and a valve Two 104, the valve one 102 and the liquid inlet of the valve are connected together through the liquid inlet pipe, and the liquid inlet of the liquid inlet pipe is connected with a pump truck 103, including the following steps:

[0047] (101) Lower the upper bound leak detection string to 20 meters above the initial leak point judgment position;

[0048] (102) Throwing ball pressure test valve 1 4, open valve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com