Novel flexible tripping structure

A flexible and new technology, applied in the protection switch operation/release mechanism, parts of the protection switch, electrical components, etc., can solve the problems of tripping, can not effectively solve the reliable closing, etc., to solve the problem of short life and small elastic deformation , the overall effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

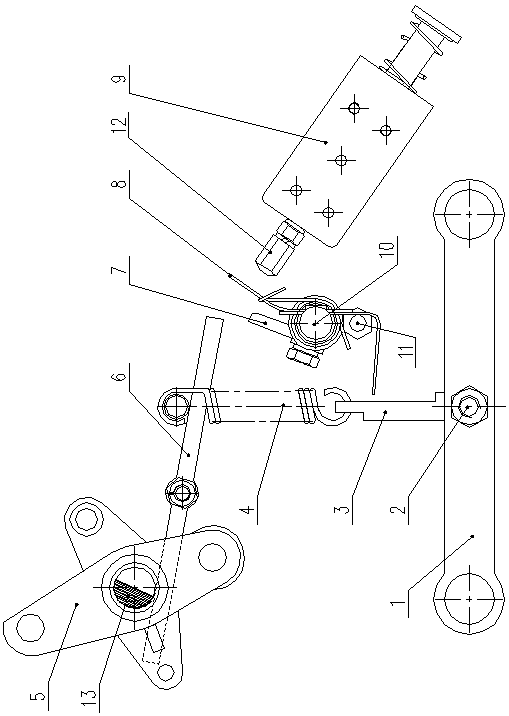

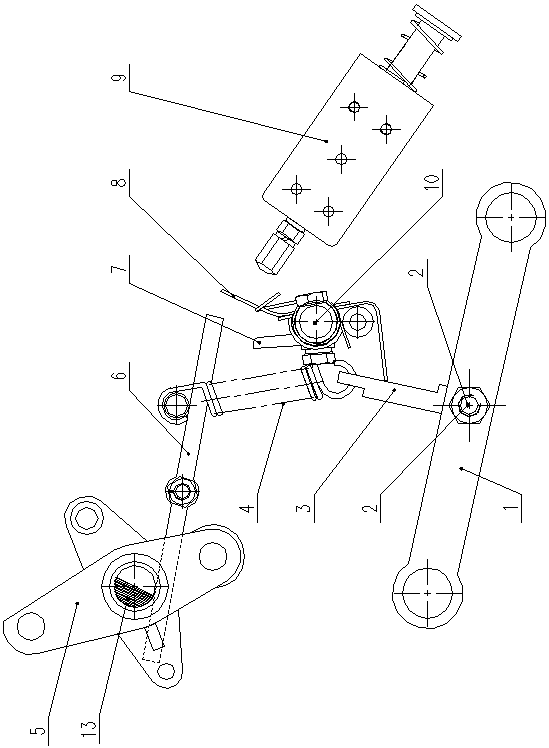

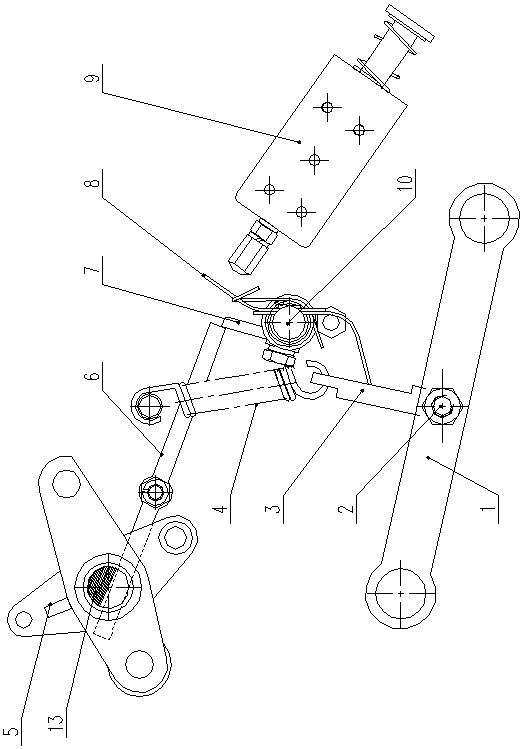

[0030] Such as Figure 1 to Figure 4 As shown, a novel flexible tripping structure of the present invention includes a manual operating mechanism, an electric operating mechanism, a closing semi-axis mechanism and an interlocking mechanism. The closing half-shaft mechanism includes a closing half-shaft 10 and a flexible trip plate 8 installed on the closing half-shaft 10 , and the closing half-shaft 10 is also connected with a closing half-shaft rotation reset device.

[0031] In this embodiment, the flexible tripping plate 8 is made of 1mm 65Mn spring steel plate, which can drive the closing half shaft 10 before elastic deformation, so as to reliably close. After closing and interlocking, the push plate is driven again, and the flexible trip plate deforms elastically, effectively realizing the closing and interlocking function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com