Slurry-free carbon fiber three-dimensional anti-twist steering industrialization device

A carbon fiber, three-dimensional technology, applied in the field of pulpless carbon fiber three-dimensional anti-twist steering industrial equipment, can solve the problems of small equipment spacing, limited equipment operation and maintenance space, and the inability to realize pulpless carbon fiber three-dimensional steering, and achieve long-lasting smoothness and durability. Excellent abrasiveness and low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

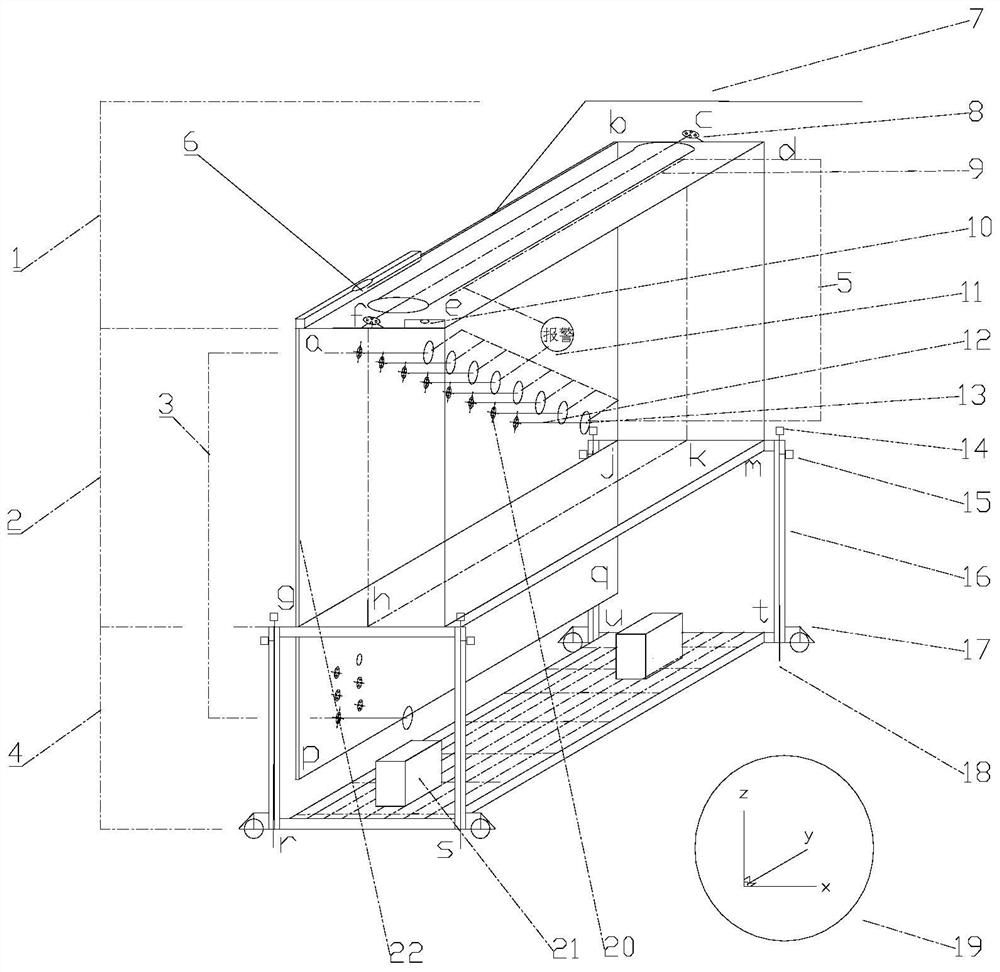

[0047] Adopt the three-dimensional anti-twisting industrialization device (as figure 1 ), which consists of: carbon fiber guiding system 1, godet wheel group fixing system 2, godet wheel group 3, base system 4, and tension test and alarm system 5. For the convenience of device operation instructions, a three-dimensional direction coordinate is added 19. Carry out a three-dimensional anti-twisting steering of 8 bundles of carbon fibers: the operation process is as follows: ⑴The device is in place: the device is moved from the universal roller 17 to the carbon fiber device before the carbon fiber sizing process or the drying process, or the washing process, or after the high carbon furnace. Place under the tow, by folding the T-square, the axial direction of the guide roller 9 is vertically aligned and fixed at 90° to the running direction of the carbon fiber tow taken. Through the Y-axis movement of the godet wheel set fixing plate 11 and the overfolding of the T-square 7, eac...

Embodiment 2

[0052] Adopt a pulpless carbon fiber three-dimensional anti-twisting industrialized device provided by the present invention such as figure 1 , whose composition removes the T-square. Carry out 8 bundles of carbon fiber three-dimensional anti-twisting steering, and the steering operation process is the same as that of Example 1.

[0053] During the three-dimensional steering process, observe the influence of carbon fiber on the unsteered carbon fiber, the steering angle, the normal running time on the equipment, the broken hair rate, the order and continuity of the continuous production of carbon fiber, and test the three-dimensional steering of this device. The bundle strength loss rate of silk carbon fiber, the results are shown in the effect comparison table 1.

Embodiment 3

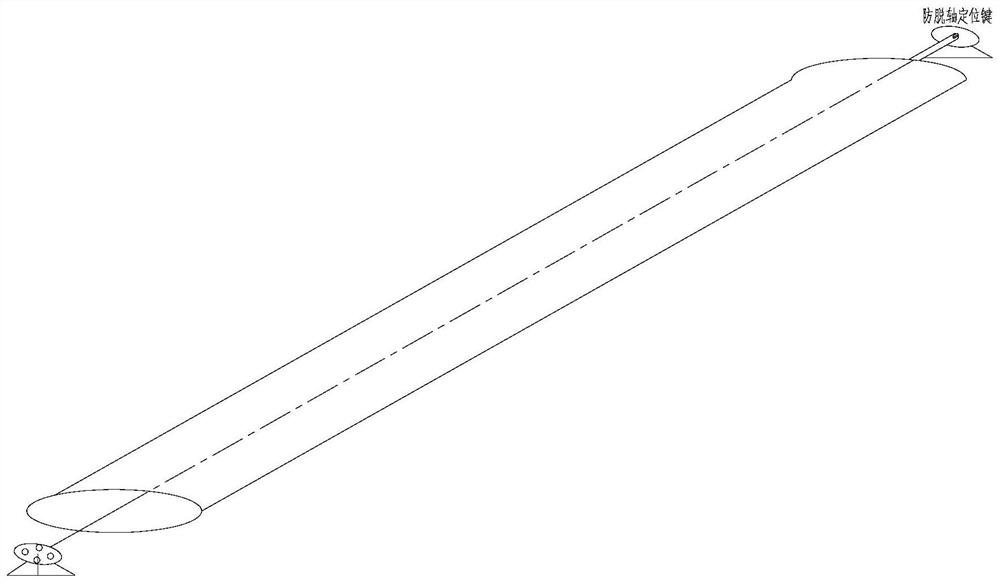

[0055] Adopt a pulpless carbon fiber three-dimensional anti-twisting industrialized device provided by the present invention such as figure 1 , in which the godet wheel set is replaced by a godet roller free metal roller of the same diameter (see Figure 13 ). Carry out 8 bundles of carbon fiber three-dimensional anti-twisting steering: the steering operation process is the same as that of Example 1.

[0056] During the three-dimensional steering process, observe the influence of carbon fiber on unsteered carbon fiber, the number of turns of carbon fiber, the angle of turn, the normal running time on equipment, the rate of broken hair, the order and continuity of continuous production of carbon fiber, and test the The bundle strength loss rate of each carbon fiber after the three-dimensional steering of the device, the results are shown in the effect comparison table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com