Thermoplastic elastomer composition as well as preparation method and application thereof

A technology of thermoplastic elastomer and composition, applied in the field of thermoplastic elastomer composition and its preparation, can solve the problems of foaming agent injection molding process and temperature sensitivity, nozzle material cannot be recycled and remanufactured, and product quality is uneven, etc., to achieve excellent Mechanical properties, ensuring the balance of product performance, and improving the effect of tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a preparation method of the thermoplastic elastomer composition, comprising the steps of:

[0061] Mixing the hollow glass microspheres, mineral oil and coupling agent to prepare mixture A;

[0062] The mixture A and the styrene block copolymer described were mixed.

[0063] By adding step by step, the hollow glass microspheres, mineral oil and coupling agent are mixed first, which is equivalent to treating the surface of the hollow glass microspheres, which is beneficial to improve the hollow glass microspheres and the styrene block. The compatibility between the copolymers and the improvement of the dispersibility of the hollow glass microspheres in the thermoplastic elastomer composition are beneficial to the performance balance of each part and can reduce the explosion rate of the hollow glass microspheres.

[0064] In one of the embodiments, the formulation of the thermoplastic elastomer composition contains thermoplastic resin ...

Embodiment 1

[0074] This embodiment provides a thermoplastic elastomer composition and a preparation method thereof.

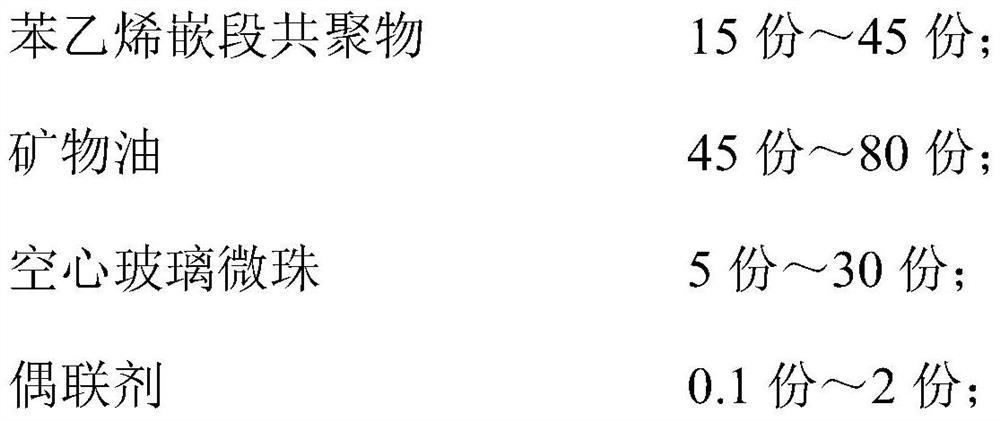

[0075] (1) In parts by weight, the raw materials for the preparation of thermoplastic elastomer composition 1 are as follows:

[0076]

[0077] (2) Preparation of thermoplastic elastomer composition 1:

[0078] a: Add mineral oil and coupling agent to the high mixer in turn, mix and stir at high speed at 50HZ, stir for 1 to 2 minutes, then add hollow glass microspheres to the high mixer, rotate at low speed at 10HZ, and stir for 2 to 5 minutes ;

[0079] b: Add the styrene block copolymer SEBS 6151 and SEBS1654 into the high mixer, mix the mixture A, rotate 10HZ at a low speed after adding, and then set the time for 5 to 10 minutes to mix the styrene block copolymer and mineral oil Uniformly and fully absorb oil to prepare mixture B;

[0080] c: Pour mixture B into the internal mixer, add thermoplastic resin HM-1000, thermoplastic polar substance EMAAC1125, antioxida...

Embodiment 2

[0083] This embodiment provides a thermoplastic elastomer composition and a preparation method thereof.

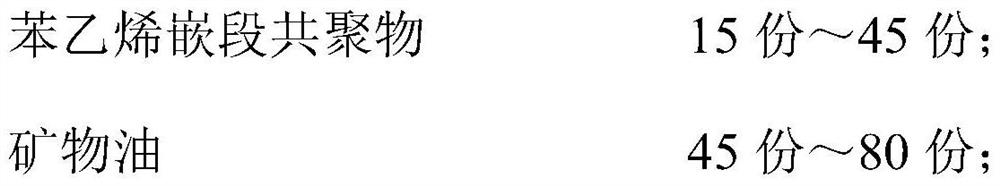

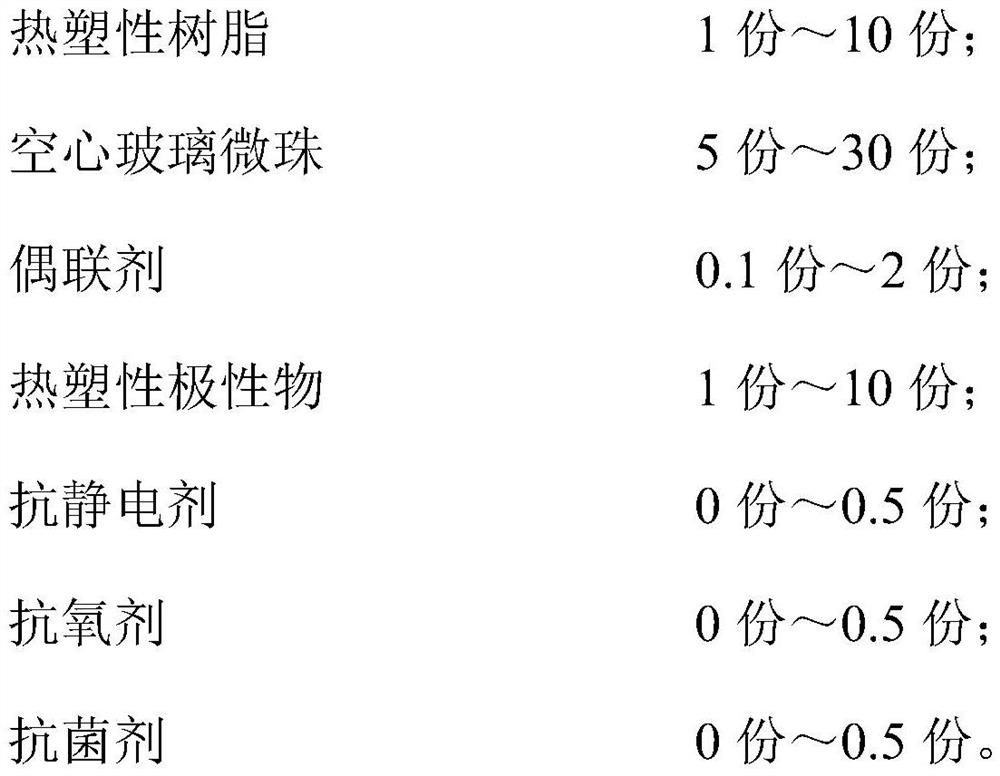

[0084] (1) In parts by weight, the raw materials for the preparation of thermoplastic elastomer composition 2 are as follows:

[0085]

[0086]

[0087] (2) Preparation of thermoplastic elastomer composition 2:

[0088] The preparation method is the same as in Example 1, and a thermoplastic elastomer composition 2 is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com