Environment-friendly high-vicat high-impact-resistance low-temperature-resistant vulcanization-pollution-resistant electric conduit and preparation method thereof

A high-dimensional card, high-impact technology, applied in the field of electrical conduit preparation, can solve the problems of easy cracking, damage and deformation, easy deformation, etc., and achieve suitable tensile properties, improve low-temperature brittleness, and good low-temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

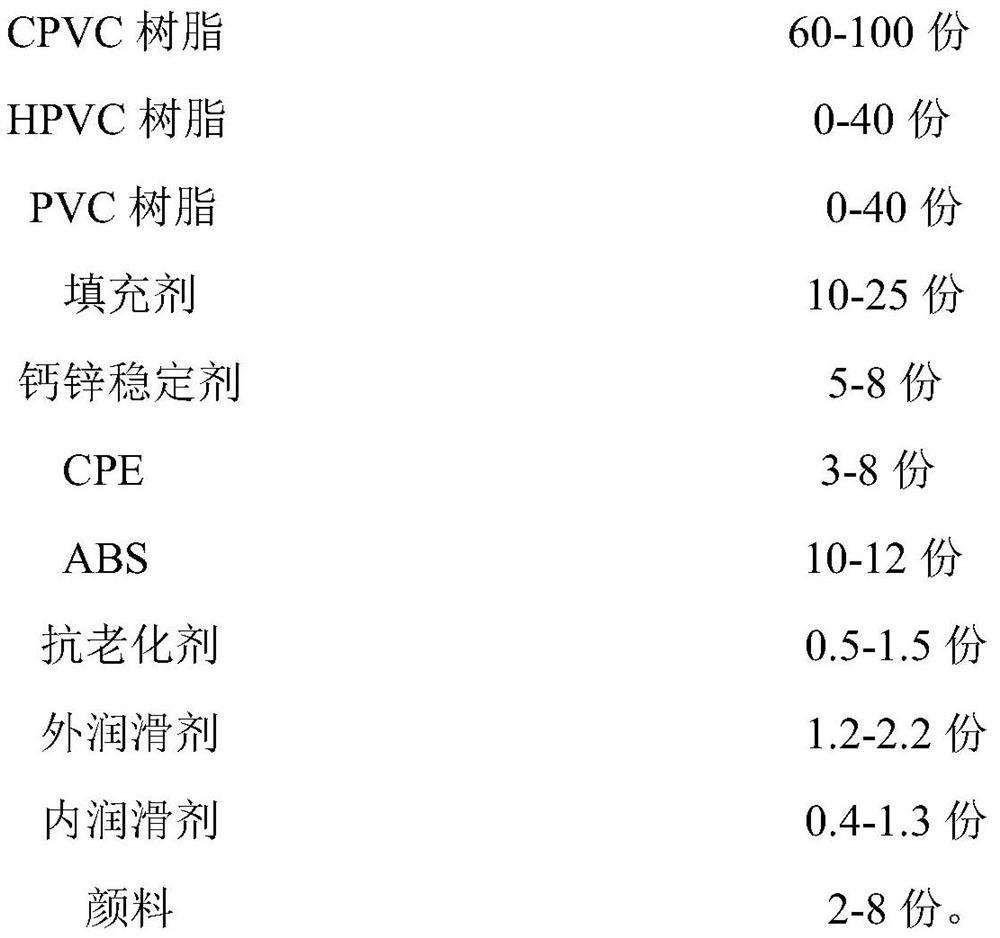

[0032] An environment-friendly high-vicat, high-impact, low-temperature, anti-vulcanization, and pollution-resistant power conduit is prepared from the following raw materials in parts by mass:

[0033]

[0034]

[0035] The preparation method of the above-mentioned environment-friendly high-vicat, high-impact, low-temperature, vulcanization-resistant and pollution-resistant power conduit is as follows:

[0036] First add CPVC resin, HPVC resin, PVC resin, nano-calcium, calcium-zinc stabilizer, CPE, ABS, titanium dioxide, high melting point wax, Fischer-Tropsch wax, monoglyceride and calcium stearate into the mixer, first at low speed Mix the materials for 10 minutes, then switch to high-speed stirring, high-speed mixing to 120°C, put in cold mixing and cool to 45°C to obtain the mixture, and transport the mixture to the twin-screw extruder, set the barrel temperature to 160-200 ℃, the confluence core temperature is 150-155℃, the template temperature is 160-190℃, the die...

Embodiment 2

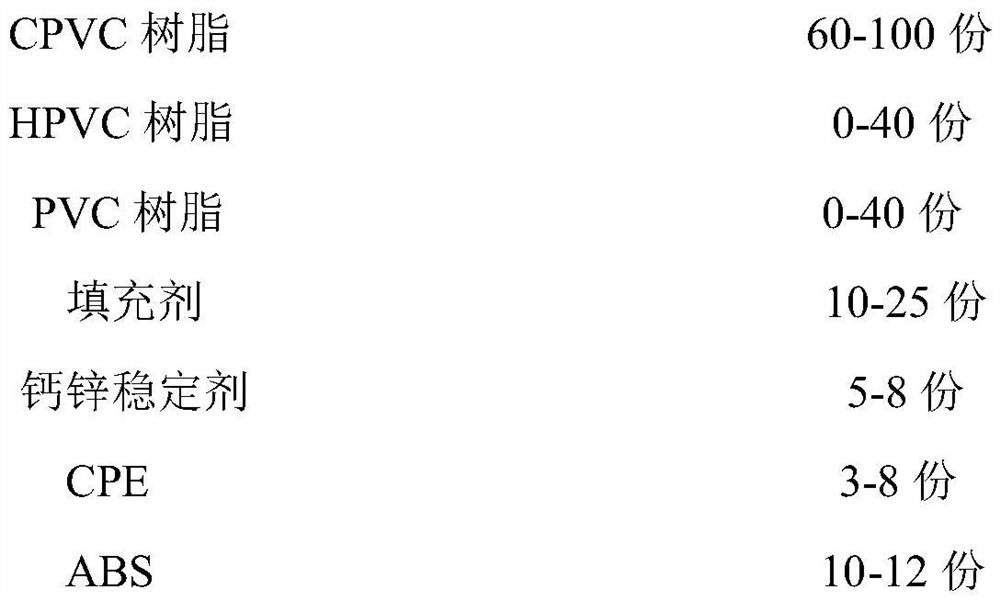

[0038] An environment-friendly high-vicat, high-impact, low-temperature, anti-vulcanization, and pollution-resistant power conduit is prepared from the following raw materials in parts by mass:

[0039]

[0040] The preparation method of the above-mentioned environment-friendly high-vicat, high-impact, low-temperature, vulcanization-resistant and pollution-resistant power conduit is as follows:

[0041] First add CPVC resin, HPVC resin, PVC resin, nano-calcium, calcium-zinc stabilizer, CPE, ABS, titanium dioxide, high melting point wax, Fischer-Tropsch wax, monoglyceride and calcium stearate into the mixer, first at low speed Mix the materials for 10 minutes, then switch to high-speed stirring, mix at high speed to 120°C, put in cold mixing and cool to 45°C to obtain the mixture, transport the mixture to the twin-screw extruder, set the barrel temperature to 160-200 ℃, the confluence core temperature is 150-155℃, the template temperature is 160-190℃, the die temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com