24KV vacuum high-voltage circuit breaker equipped with small modular spring operating mechanism

A high-voltage circuit breaker and operating mechanism technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of complex structure, large space, and many parts, and achieve long life and low noise , reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

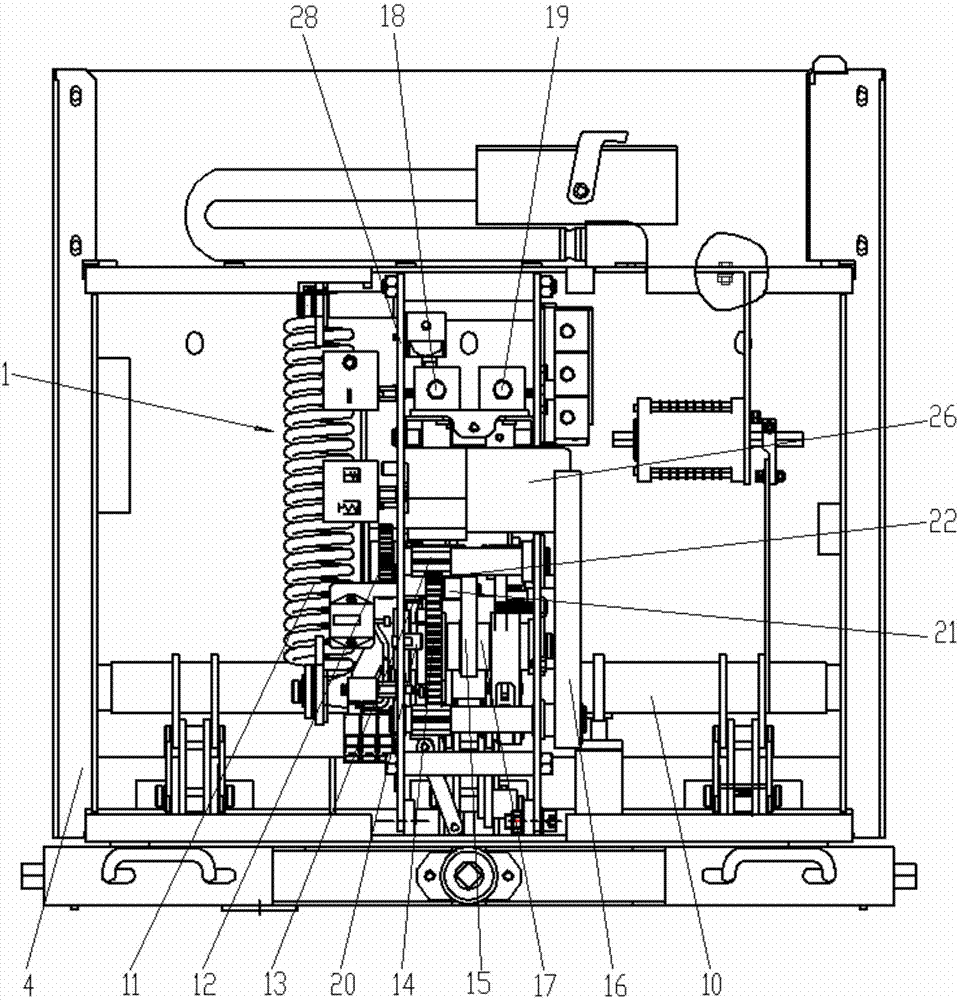

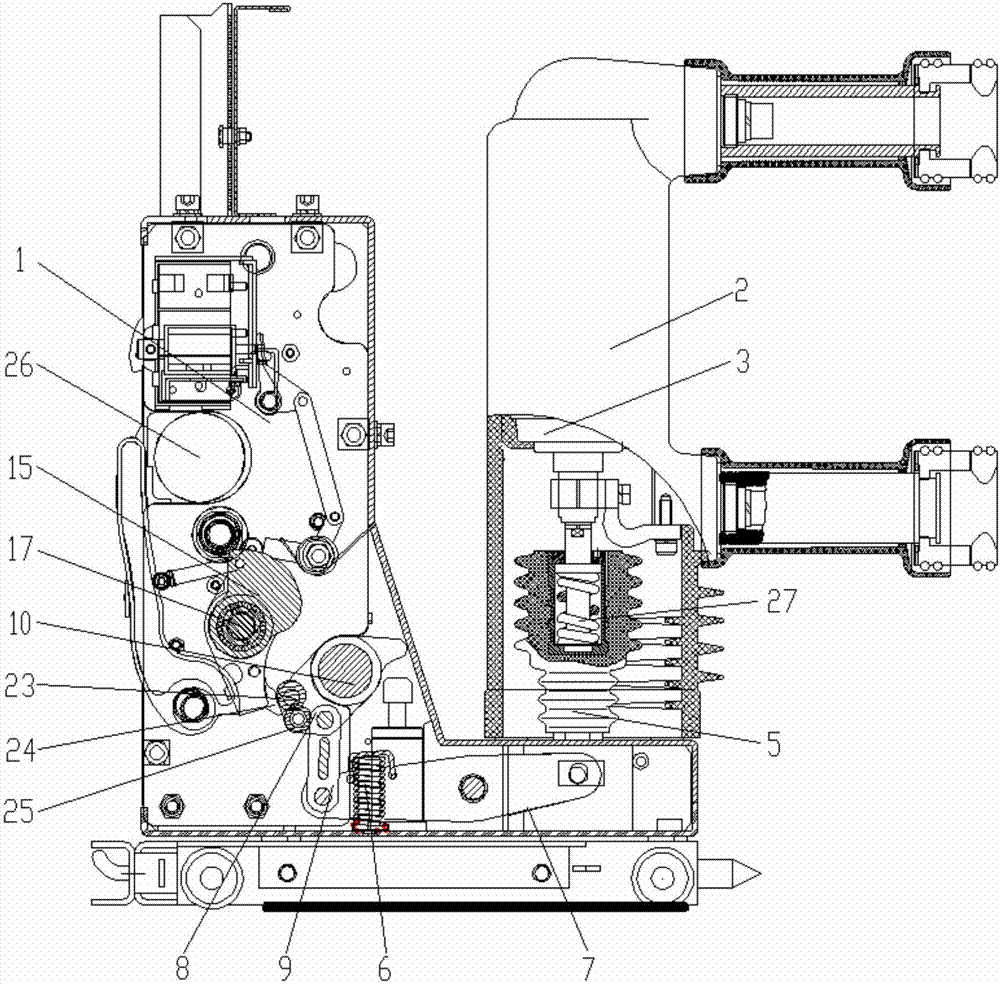

[0013] Attached below Figure 1-2 Embodiments of the present invention are described.

[0014] 24KV vacuum high voltage circuit breaker with small modular spring operating mechanism, such as figure 1 and 2 As shown, there is a box body 4, and the inside of the box body 4 is provided with a solid-sealed pole 2 and a VSH small modular spring operating mechanism 1, and the interior of the solid-sealed pole 2 is provided with a vacuum interrupter 3. The vacuum interrupter 3 is cast on the solid-sealed pole 2 with APG epoxy resin, which simplifies the complex assembly and adjustment links of the three-phase main circuit, reduces the possible damage to the vacuum interrupter during the assembly process and reduces the number of bolts used. The connection is loosened due to vibration. The unique epoxy resin pole has anti-aging, high temperature resistance, low temperature resistance and high mechanical strength, which completely avoids the external surface of the vacuum circuit bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com