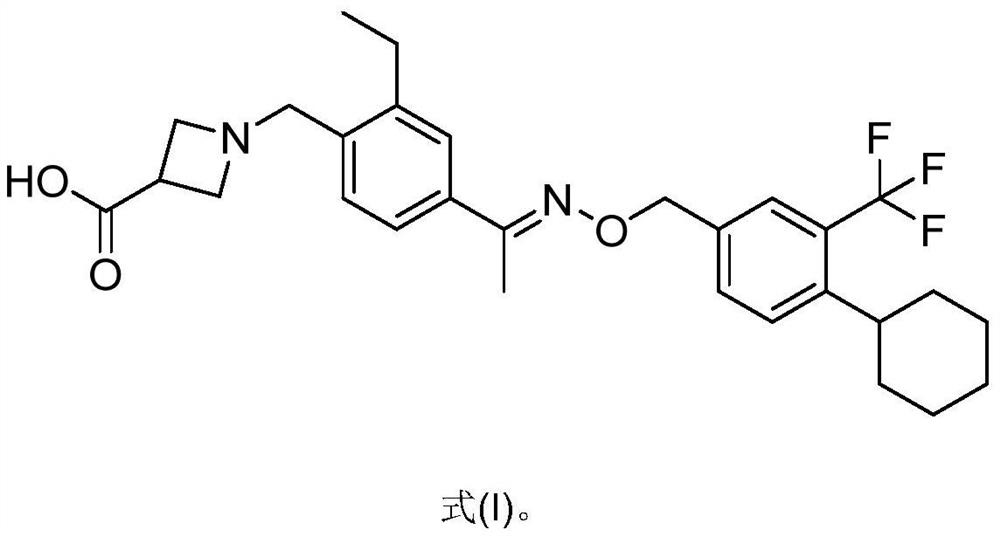

Preparation method of siponimod intermediate

A technology of inert gases and compounds, applied in the field of preparation of siponimod intermediates, can solve the problem of high cost, achieve the effects of reducing three wastes, reducing costs, and removing impurities efficiently and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

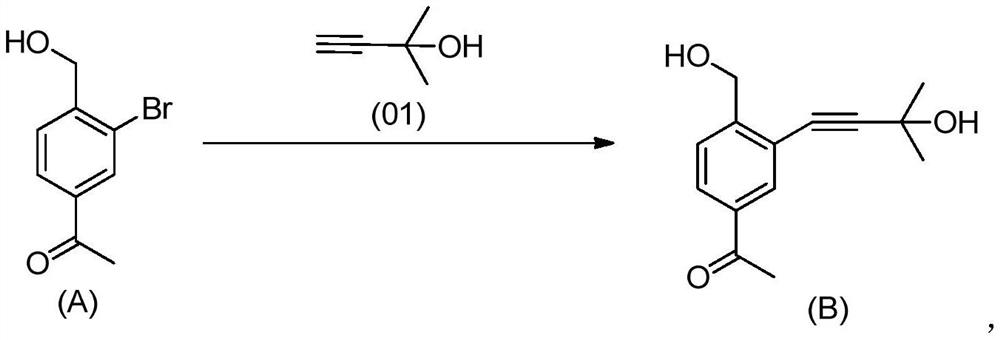

[0068] The preparation of embodiment 1 compound (B)

[0069] Add compound (A) (15.00g), 2-methyl-3-butyn-2-alcohol (7.16g), Pd(dppf)Cl in the reaction flask 2 (0.96g), cuprous iodide (0.62g), and TEA (150mL), the air in the reaction flask was replaced with nitrogen 3 times, and the temperature was raised to 80°C under stirring, and the reaction was continued until the reaction was detected by HPLC. Cool the reaction solution to room temperature, filter with suction, spin dry the filtrate, add 45ml of water to the spin-dried product, extract 30ml*3 times with EA, combine the organic layers and spin dry, and recrystallize the spin-dried product in toluene to obtain compound (B): 13.42g The yield is 88%, detection: purity 98%, MS: [M+1]=233.1, NMR: 1H NMR (400MHz, DMSO-d6): δ1.50 (6H, s), 2.58 (3H, s) 4.67~4.69(2H,d), 5.45~5.48(1H,t), 5.52(1H,s), 7.65~7.67(1H,d), 7.86(1H,s), 7.86~7.93(1H,d).

Embodiment 2

[0070] The preparation of embodiment 2 compound (B)

[0071] Add compound (A) (15.00g), 2-methyl-3-butyn-2-alcohol (7.16g), Pd(dppf)Cl in the reaction flask 2 (0.96g), cuprous iodide (1.24g), and DIPEA (150mL), the air in the reaction flask was replaced with nitrogen 3 times, the temperature was raised to 80°C under stirring, and the reaction was continued until the reaction was detected by HPLC. Cool the reaction solution to room temperature, filter with suction, spin dry the filtrate, add 45ml of water to the spin-dried product, extract 30ml*3 times with EA, combine the organic layers and spin dry, and recrystallize the spin-dried product in toluene to obtain compound (B): 11.44g ; Yield is 75%, detection: purity 96%.

Embodiment 3

[0072] The preparation of embodiment 3 compound (B)

[0073]Add compound (A) (15.00g), 2-methyl-3-butyn-2-alcohol (7.16g), dichloroditriphenylphosphine palladium (0.92g), cuprous iodide ( 0.93g), and TEA (150mL), the air in the reaction flask was replaced with nitrogen for 3 times, the temperature was raised to 80°C under stirring, and the reaction was continued until the reaction was detected by HPLC. Cool the reaction solution to room temperature, filter with suction, spin dry the filtrate, add 45ml of water to the spin-dried product, extract 30ml*3 times with EA, combine the organic layer and spin-dry, and recrystallize the spin-dried product in toluene to obtain compound (B): 12.35g ; Yield is 81%, detection: purity 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com