Suspended alkali-free liquid accelerator and preparation method thereof

A technology of quick-setting agent and liquid, which is applied in the field of suspension-type non-alkali liquid quick-setting agent and its preparation. It can solve the problems of ready-mixed concrete spraying, high requirements for spraying machinery, and pipe plugging of spraying machinery, so as to reduce pipe plugging. , Good coagulation effect, early strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

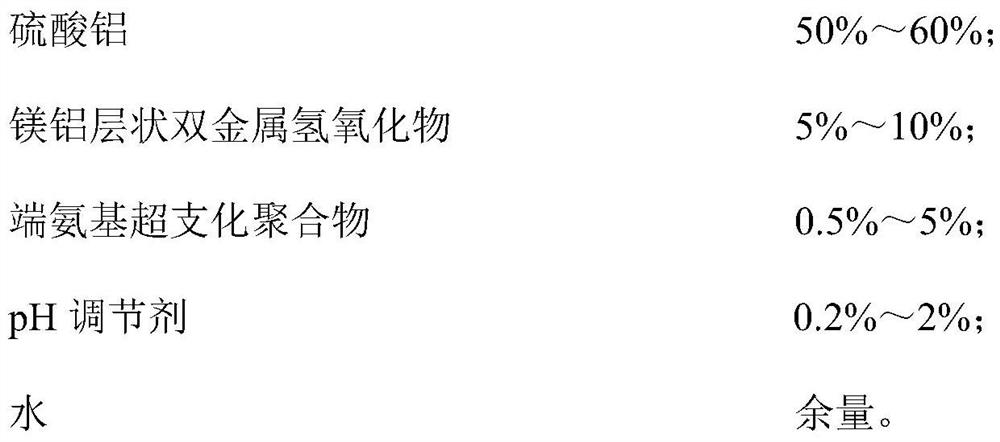

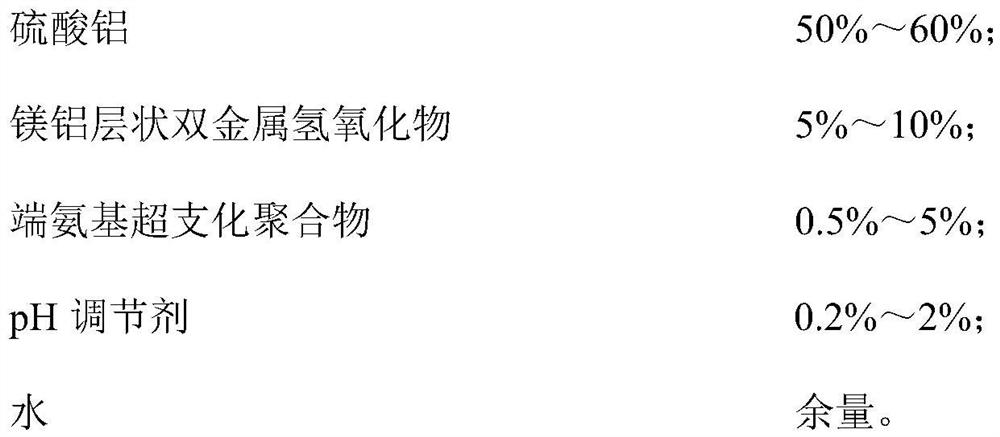

[0036] A suspension-type non-alkali liquid quick-setting agent of the present embodiment includes the following components in mass percentage:

[0037]

[0038] A suspension type non-alkali liquid quick-setting agent of the present embodiment is prepared by the following method:

[0039] (1) Preparation of magnesium-aluminum layered double metal hydroxide: magnesium sulfate and aluminum sulfate are pressed by Mg 2+ / Al 3+ Dissolve in a mixed solvent of water and N,N-dimethylformamide with a volume ratio of 1:2 at a molar ratio of 2:1, then add sodium hydroxide and stir to mix evenly, and then heat it in water at a temperature of 120-150°C After the reaction, the solid product is filtered, washed, dried and ground to obtain nano-sized magnesium-aluminum layered double metal hydroxide.

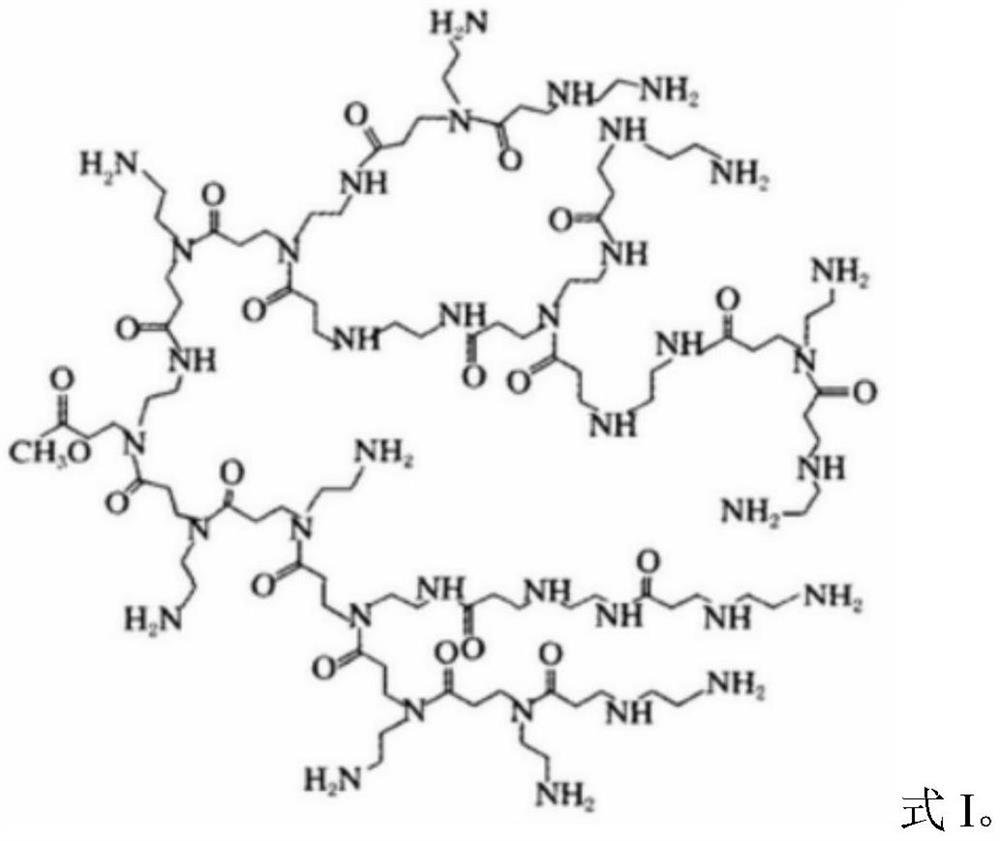

[0040] (2) Preparation of amino-terminated hyperbranched polymer: Add N,N-methylenebisacrylamide and diethylenetriamine at a molar ratio of 1:1.5 into N,N-dimethylformamide solvent, and then ...

Embodiment 2

[0043] A suspension-type non-alkali liquid quick-setting agent of the present embodiment includes the following components in mass percentage:

[0044]

[0045] A suspension type non-alkali liquid quick-setting agent of the present embodiment is prepared by the following method:

[0046] (1) Preparation of magnesium-aluminum layered double metal hydroxide: magnesium sulfate and aluminum sulfate are pressed by Mg 2+ / Al 3+ Dissolve in a mixed solvent of water and N,N-dimethylformamide with a volume ratio of 1:2 at a molar ratio of 3:1, then add sodium hydroxide and stir to mix evenly, and then heat it in water at a temperature of 120-150°C After the reaction, the solid product is filtered, washed, dried and ground to obtain nano-sized magnesium-aluminum layered double metal hydroxide.

[0047] (2) Preparation of amino-terminated hyperbranched polymer: Add N,N-methylenebisacrylamide and diethylenetriamine at a molar ratio of 1:1.5 into N,N-dimethylformamide solvent, and the...

Embodiment 3

[0050] A suspension-type non-alkali liquid quick-setting agent of the present embodiment includes the following components in mass percentage:

[0051]

[0052] A suspension type non-alkali liquid quick-setting agent of the present embodiment is prepared by the following method:

[0053] (1) Preparation of magnesium-aluminum layered double metal hydroxide: magnesium sulfate and aluminum sulfate are pressed by Mg 2+ / Al 3+ The molar ratio is 4:1, dissolved in a mixed solvent of water and N,N-dimethylformamide with a volume ratio of 1:2, then adding sodium hydroxide and stirring to mix evenly, and then hydrothermally After the reaction, the solid product is filtered, washed, dried and ground to obtain nano-sized magnesium-aluminum layered double metal hydroxide.

[0054] (2) Preparation of amino-terminated hyperbranched polymer: Add N,N-methylenebisacrylamide and diethylenetriamine at a molar ratio of 1:1.2 into N,N-dimethylformamide solvent, and then Add N,N-methylenebisa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com