Dust fall and leakage-proof intelligent system and method for coal conveying belt of thermal power plant

A technology for thermal power plants and belts, which is applied in the field of dust-reducing and leak-proof intelligent systems for coal conveying belts in thermal power plants. It can solve the problems of inconvenient transformation, high investment cost, and insufficient intelligence level, etc., and achieves convenient changes, intelligentization, and material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

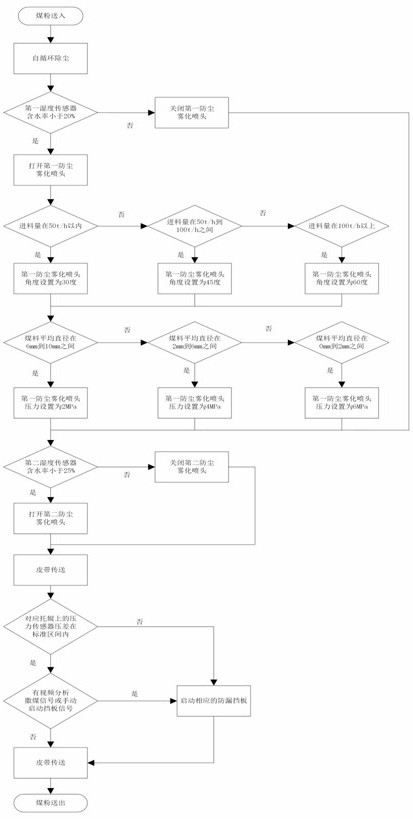

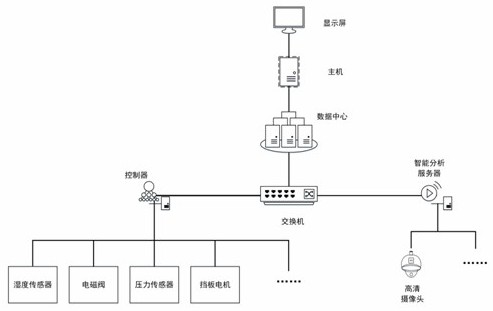

[0078] Such as figure 1 , figure 2 As shown, a thermal power plant coal conveyor belt dust reduction and leakage prevention intelligent system includes: self-circulation area 1, humidification chamber 2, humidity sensor, humidification device, leakage prevention baffle 5, camera 7 and controller 8.

[0079] The self-circulation area 1 is set on the coal-falling pipe, and the self-circulation area 1 includes the main pipe 101 of the coal-falling pipe, the first auxiliary pipe 102 and the second auxiliary pipe 103, and the first auxiliary pipe 102 and the second The two secondary pipelines 103 are reversely connected to the coal outlet and coal inlet of the main pipeline 101 of the coal falling pipe to form a semi-closed pipeline, and the coal dust is separated by the pressure difference generated when the material coal falls and formed in the main and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com