Reaction kettle for continuous chlorination

A technology of reactor and continuous method, which is applied in the field of reactor for continuous chlorination, can solve the problems of inconvenient cleaning of the reactor, and achieve the effect of increasing the speed of chlorination reaction and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

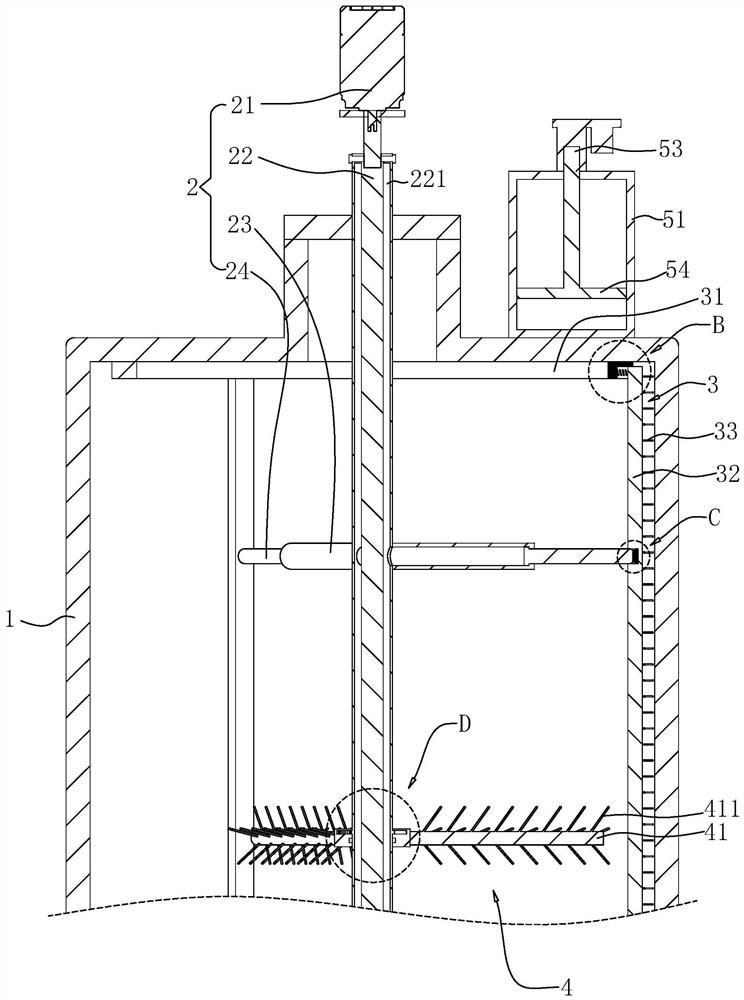

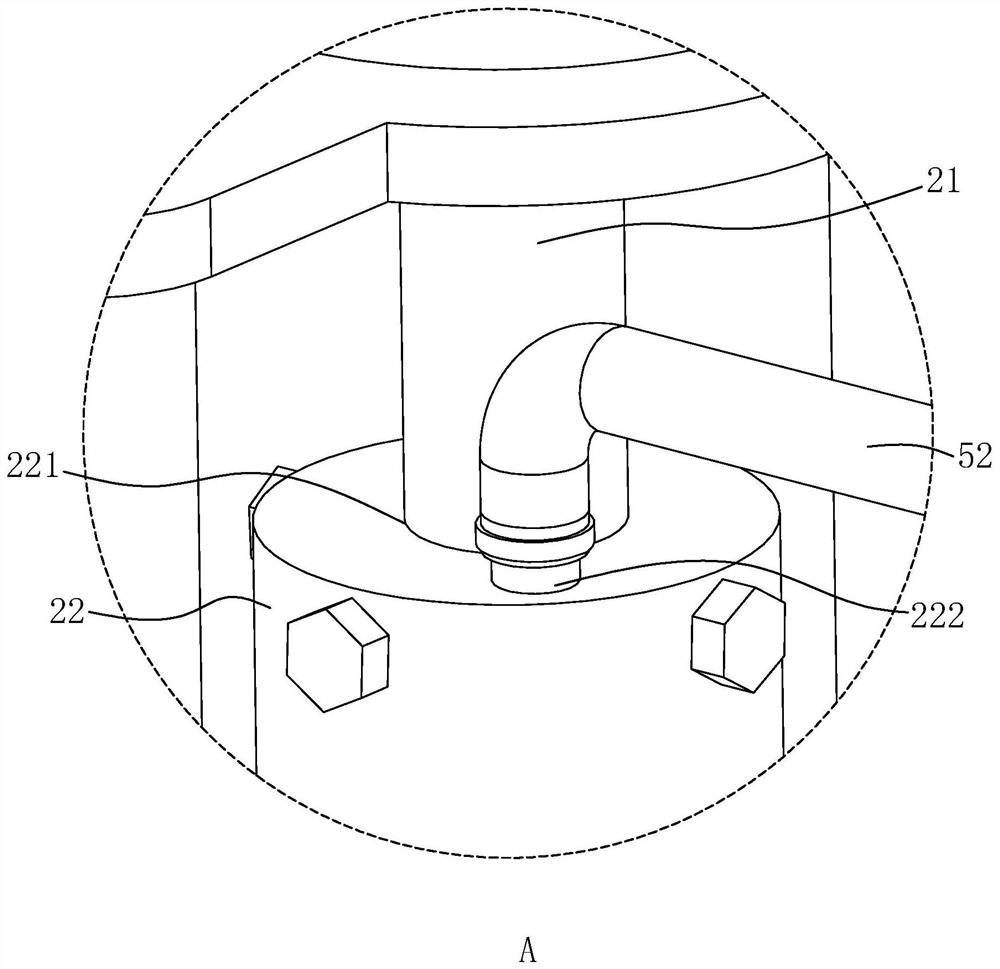

[0038] The following is attached Figure 1-6 The application is described in further detail.

[0039] The embodiment of the present application discloses a reactor for continuous process chlorination.

[0040] refer to figure 1 with figure 2 A reactor for continuous chlorination includes a reactor body 1 , a stirring assembly 2 , a cleaning assembly 3 , a defoaming assembly 4 and a hydraulic assembly 5 . Stirring assembly 2 is arranged on the reactor body 1 close to the central axis, so as to stir and mix the material inside the reactor body 1 to improve the reaction rate; 2 Drive the rotation to improve the complete reaction rate between materials on the premise of improving the uniformity of material mixing, and at the same time break the chlorine gas bubbles inside the reaction liquid smaller, increasing the contact area between chlorine gas and materials, thus The degree of combination of chlorine gas and reaction substances is improved, and the reaction speed of chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com