Radial adsorption tower and adsorption process

An adsorption tower and adsorbent technology, which is used in the field of petrochemical gas adsorption and separation, can solve the problems of affecting the performance of the adsorbent, gas phase entrainment and incomplete desorption of the adsorbent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 is a purification process of catalytic reforming by-product hydrogen. The reformed hydrogen flow rate is 87347Nm 3 / h, the reformed hydrogen composition is shown in Table 1.

[0057] Table 1 Reformed Hydrogen Composition

[0058]

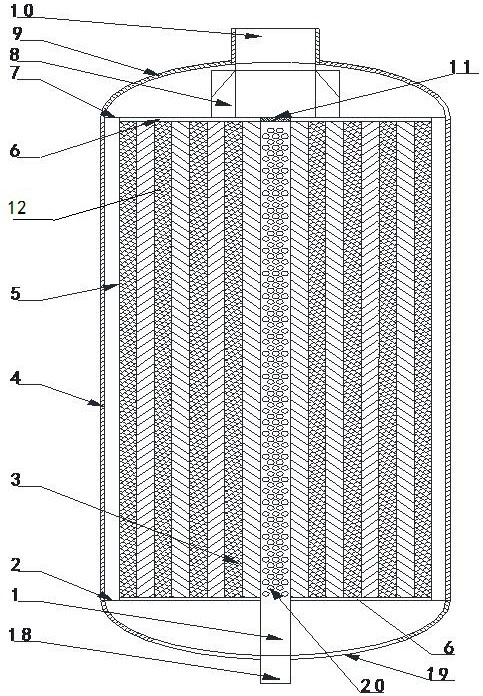

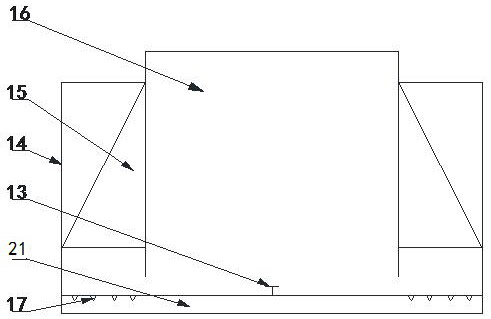

[0059] The adsorption tower of this embodiment adopts the adsorption tower and adsorbent filling technology of the present invention. The adsorption process requires four proprietary adsorbents, adsorbents a, b, c, and d. According to the specific implementation method, the four kinds of adsorbents are sequentially made into wire mesh roll columns according to the packing volume, and the packing volume ratio of the four kinds of adsorbents is 25:30:30:15. The operating conditions of the adsorption tower are shown in Table 2.

[0060] Table 2 Operating conditions of adsorption tower

[0061]

[0062] The reforming by-product hydrogen enters the adsorption tower through the central pipe, and the small molecular hydrocarbons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com