A belt type sucrose 6 ester synthesis equipment

A synthesis equipment and belt-type technology, applied in the field of organic matter evaporation, can solve the problems of lengthening production process, lowering production efficiency, and affecting the continuity of the production process of sucrose-6-ester synthesis, so as to achieve faster synthesis speed, sufficient cooling time, The effect of high social use value and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

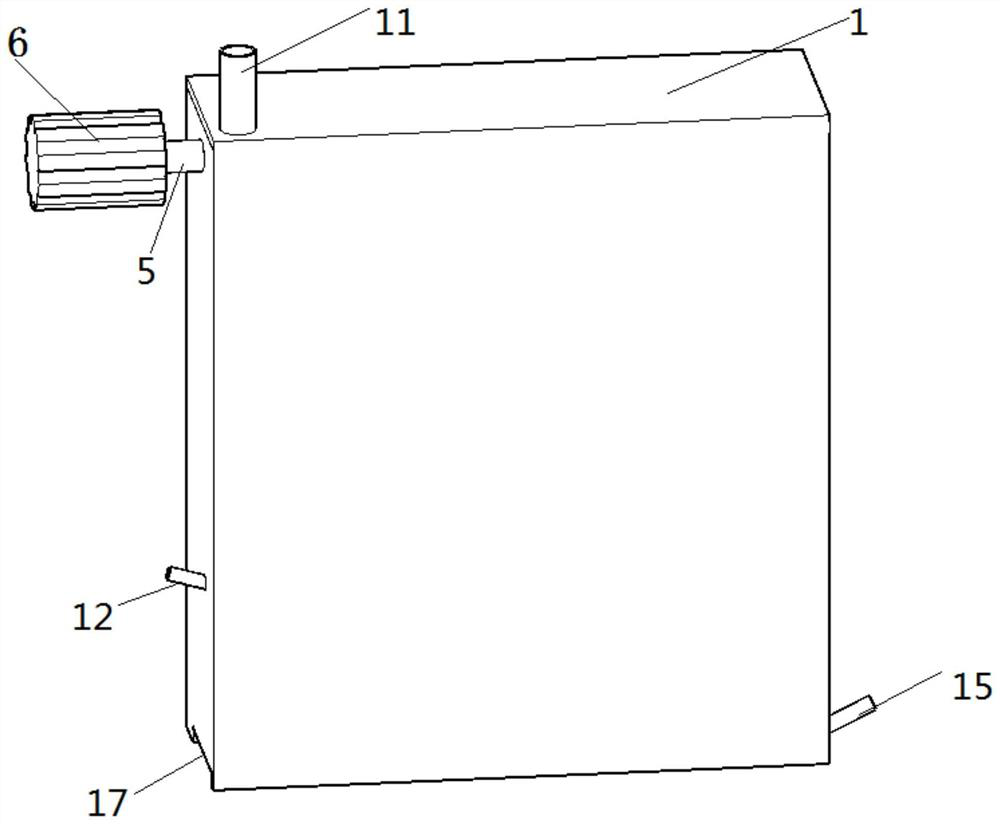

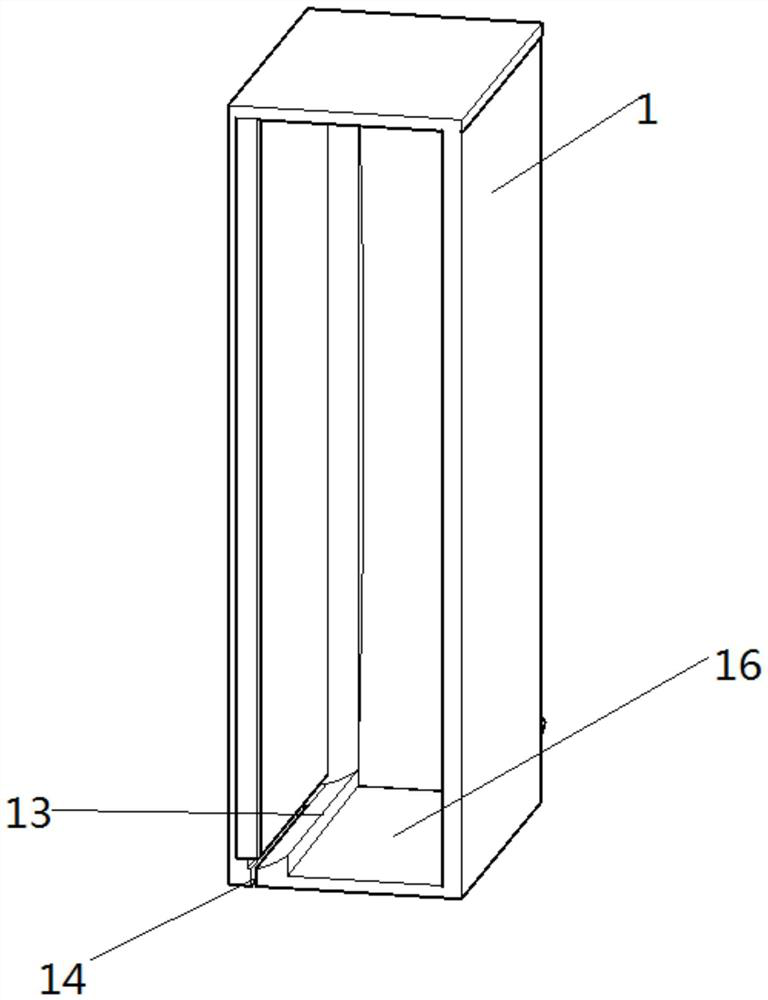

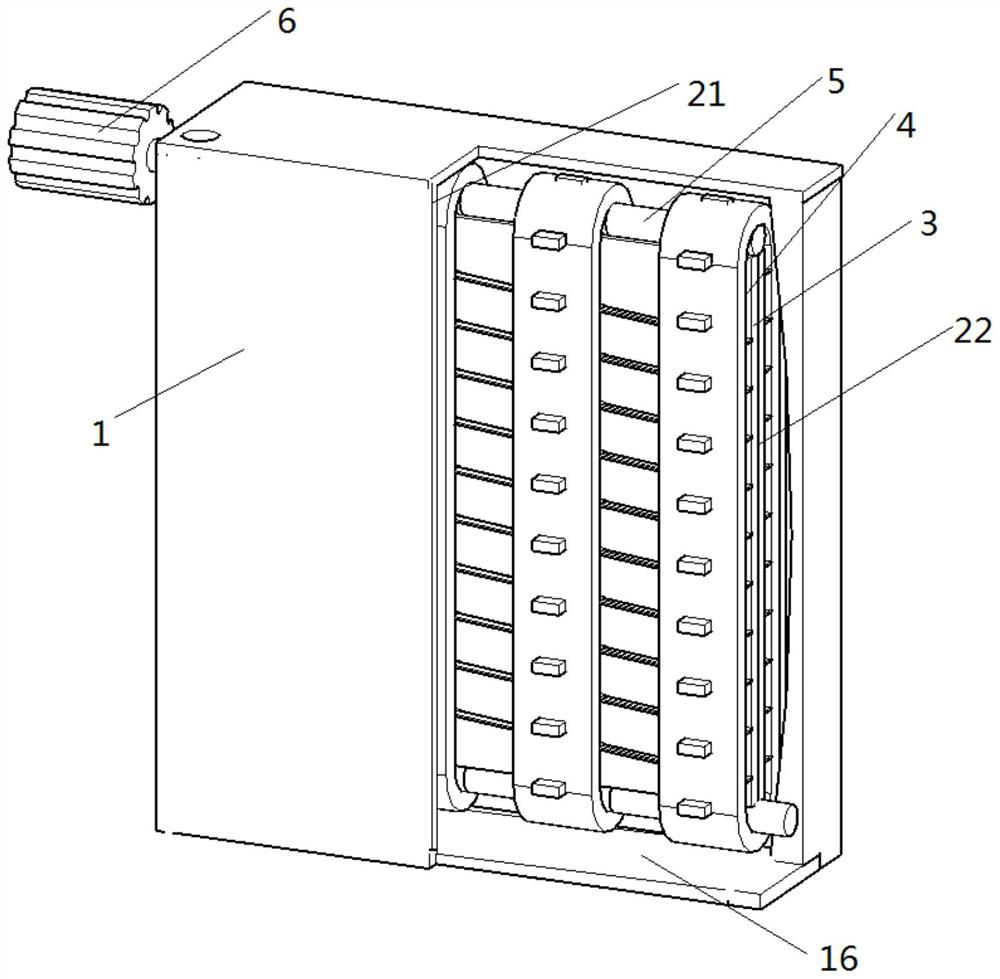

[0031] like Figure 1-3 As shown, the tank body 1 includes: a vacuum pumping pipe 11, a liquid inlet pipe 12, a guide plate 13, a liquid outlet 14, a feed pipe 15, a guide plate 2 16, and a discharge port 17;

[0032] The overall shape of the tank body 1 is square, and its upper end is provided with a vacuum exhaust pipe 11, so that the inside of the tank body is in a vacuum state, which is conducive to the evaporation of the first mixed liquid;

[0033] The liquid inlet pipe 12 is arranged on the wall surface of the tank body 1 close to the vacuum pumping pipe 11, and it is arranged obliquely downward along the wall surface of the tank body 1. When the first mixed liquid flows into the tank body 1 from the liquid inlet pipe 12, it is The lower power falls on the heating plate 4 and the rotating device 5;

[0034] The side of the tank body 1 is provided with a condensing plate-21, which is square in shape and fits with the inner wall of the tank body 1, and a guide plate-13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com