Static electricity removing device used in light diffusion plate production

A technology of static electricity removal device and light diffusion plate, which is applied in the direction of static electricity and electrical components, can solve the problems of reducing the light transmittance of the light diffusion plate and increasing production costs, and achieves the effect of good conductivity, strong applicability, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

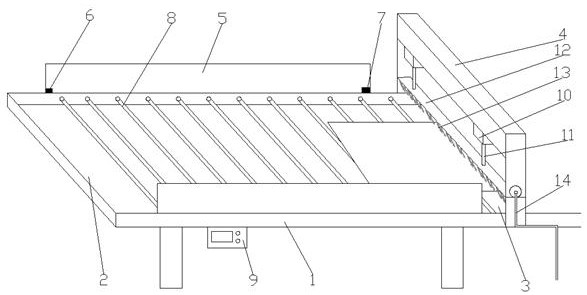

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0017] Such as figure 1 A static elimination device used in the production of light diffusion plates is shown, including a transport frame 1, the left side of the transport frame is the material inlet 2, and the right side is the material output port 3, and the transport frame 1 is close to the discharge port. A support frame 4 is fixedly connected above the end of the mouth 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com