Electric connector

An electrical connector and electrical connection technology, which is applied in the direction of connection, parts and circuits of connection devices, can solve the problems of increasing design difficulty, increasing processing cost, and easy shaking, so as to reduce the number of terminal assemblies, prevent collision interference, The effect of improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

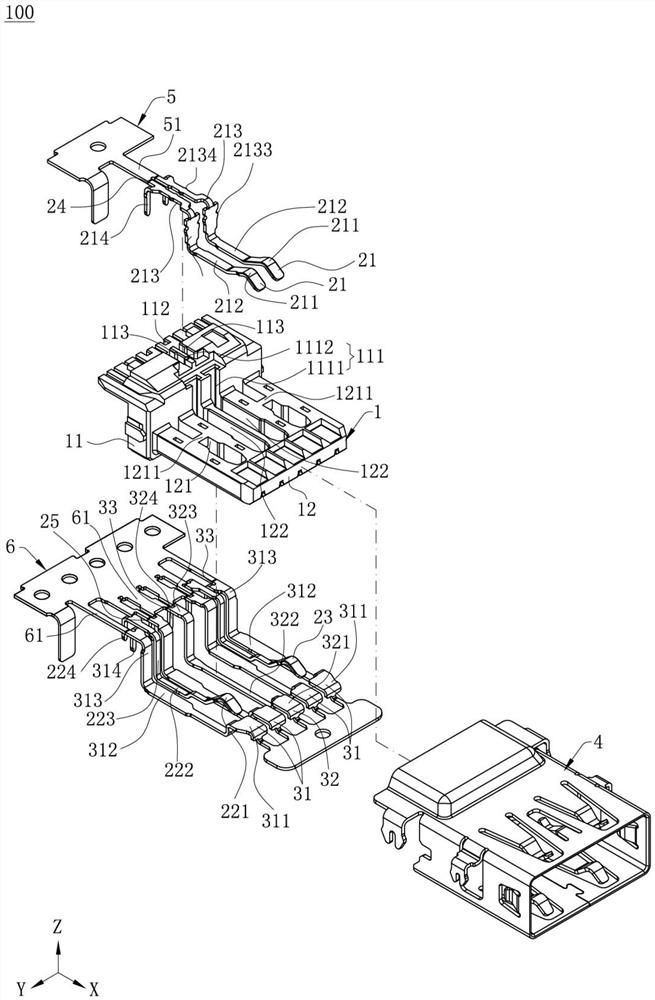

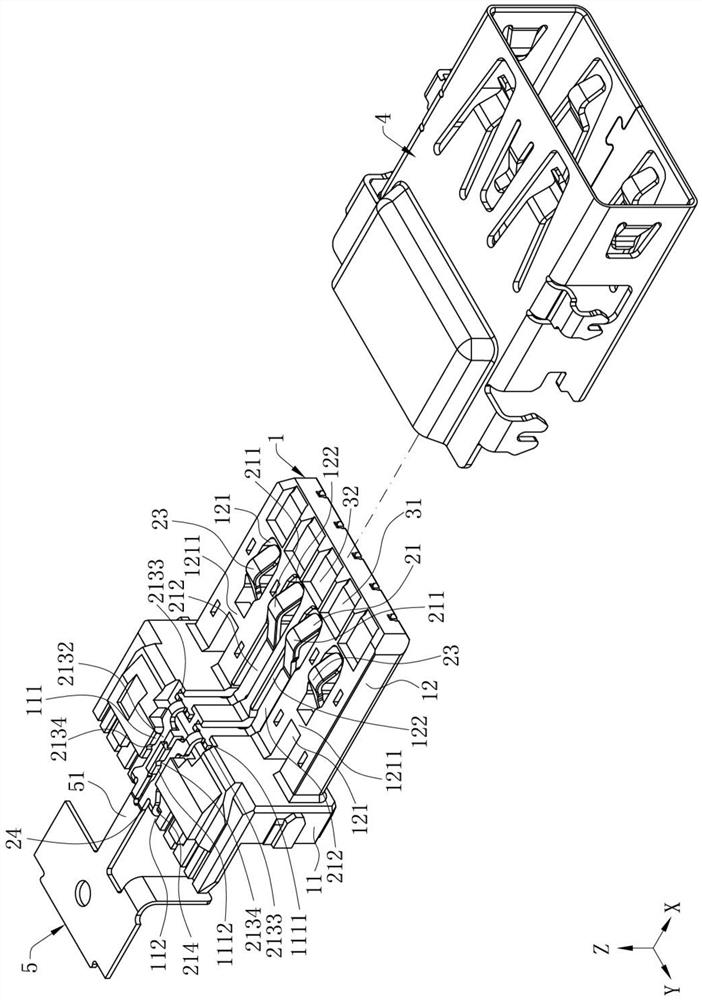

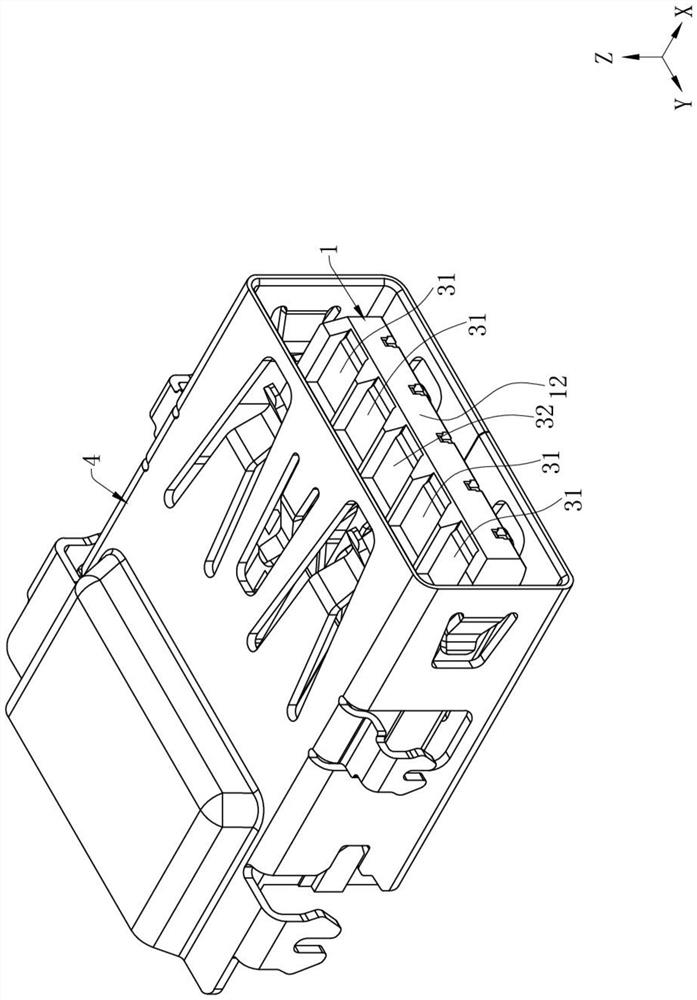

[0041] Such as Figure 1 to Figure 3 As shown, the electrical connector 100 of the present invention is used to dock with a docking connector (not shown) forward. In this embodiment, the electrical connector 100 is a USB 3.1 connector. Of course, in other embodiments, the The electrical connector 100 may also be other connectors for transmitting high-frequency signals. For the convenience of description, the direction in which the electrical connector 100 is docked with the butt connector is set as the front-rear direction, wherein the X-axis is the front-rear direction, the arrow direction of the X-axis is the forward direction, the Y-axis is the left-right direction, and the Y-axis is the left-right direction. The arrow direction of the axis is the right direction, the Z axis is the up and down direction, and the arrow direction of the Z axis is the upward direction.

[0042] Such as Figure 1 to Figure 3 As shown, the electrical connector 100 includes an insulating body 1...

Embodiment 2

[0058] Such as Figure 9 to Figure 12 As shown, in this embodiment, the structure of the electrical connector 100 is basically the same as the structure of the electrical connector 100 in Embodiment 1, the difference is that the second ground connection part 3232 and the differential connection part 3132 are located On the same plane, part of the first ground connection part 2232 and part of the power supply connection part are located on the same plane as the signal connection part 2132 and are located on a different plane from the second ground connection part 3232 and the differential connection part 3132 , under the premise that the first ground connection part 2232, the power supply connection part, the second ground connection part 3232, and the differential connection part 3132 are co-injection-molded on the insulating body 1, the first ground connection part 2232 is located on the same plane as the signal connection part 2132, so that the interference signal of the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com