Launching mechanism based on elastic ejector pin

A launch mechanism and elastic thimble technology, which is applied to launchers operated by friction wheels, weapons without explosives, throwing weapons, etc., can solve problems affecting launch accuracy and ejection, and achieve improved launch accuracy, simple and reliable control, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

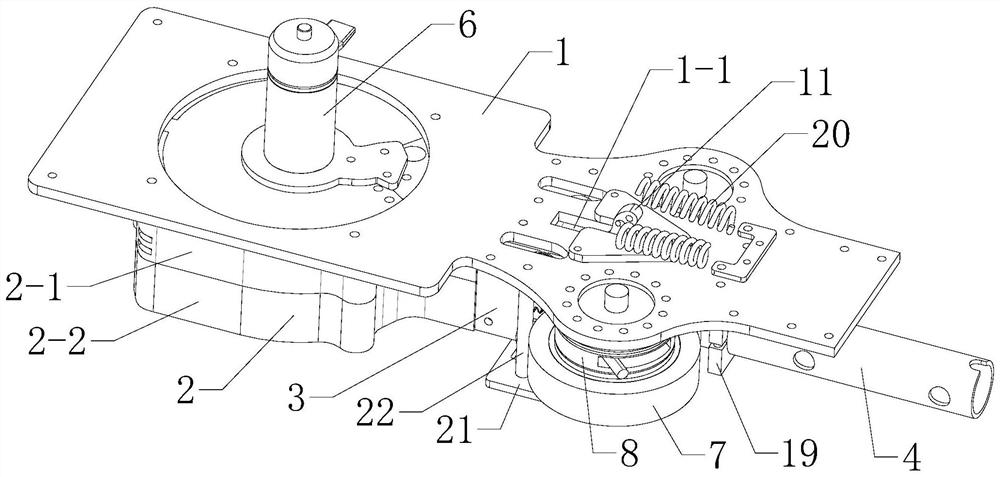

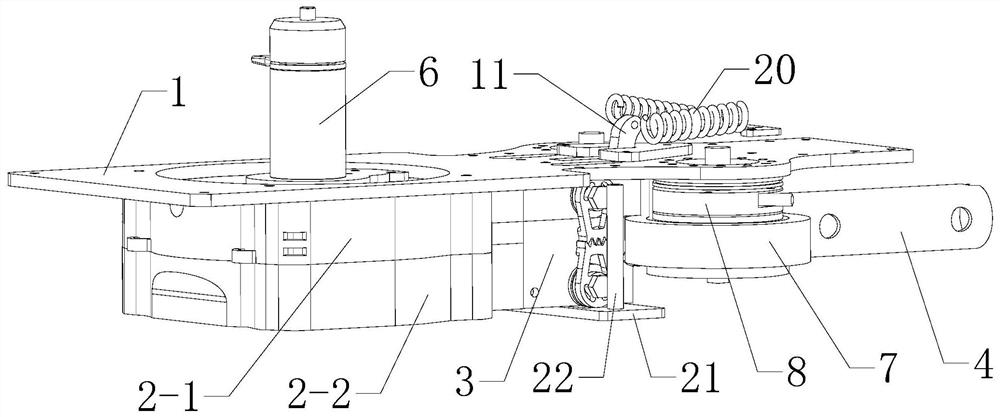

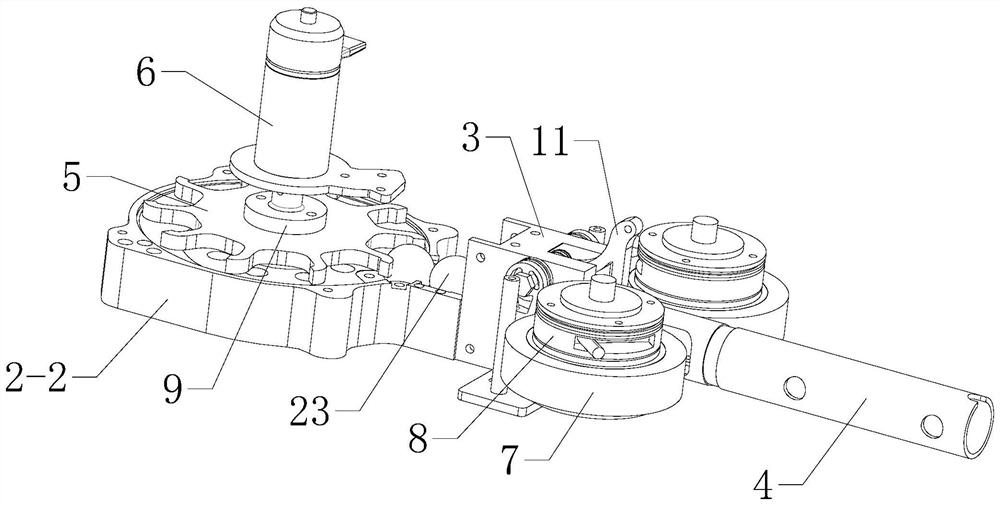

[0026]Such asFigure 1 to 4 As shown, a transmitting mechanism based on an elastic thim needle, including a top plate, a bottom fixed connection between the top plate, and a reservoir, the balloon is connected, and the top needle fixation is provided with a ball. Hole, the tip fixture is connected to the emitting pipe, and the eradic conductors are communicated with the transmitting pipe; the bolt is rotated to be connected to the dial, the dial is driven by the dial motor, and the top needle fixing is provided is used for clamping or loosening. The limit clamp of the projectile that enters the transmitting conduit, the left and right sides of the transmitting conduit are sided, and the opening is provided with an opening friction wheel at both sides of the transmitting conduit, and the emitting friction wheel is driven by a brushless motor. Front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com